2. Connect water hoses from the property’s cold water

supply to connections (EP14-XL1) and (EP15-XL1).

3. Open the water supply and flush the system for 10

minutes.

4. Shut off the water supply, empty the system and

disconnect the drain hoses from (EP14-XL2) and (15).

5. Close connections (EP14-XL2) and (EP15-XL2) using

end caps (not enclosed) that can withstand a pres-

sure of up to 4 bar.

6. Open the water supply and raise the pressure to 4

bar. Read off the pressure gauge (not enclosed),

which is installed in the water supply system.

7. Shut off the water supply once the pressure reaches

the desired level.

8. Leave the system pressurised for at least 6 hours.

Write a suitable report for the test results.

9. Check carefully for any leakage. If leaks are dis-

covered, these must be repaired. Then follow the

above points again until all leaks have been elimin-

ated.

10. When the heating medium system has passed the

pressure test, empty the heating medium system

and remove all connected hoses.

Caution

Use suitable drainage systems according

to local legislation to empty the pipe sys-

tem.

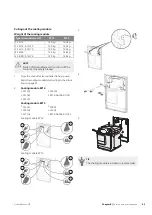

Connections, heating medium: 3-12/12, 3-16/12, 3-16/15

EP14-XL2

EP15-XL2

EP14-XL1

EP15-XL1

XL40

Connections, heating medium: 4-16/12, 4-16/15, 4-

16/20, 4-16/30, 5-16/30

UN

EP14-XL2

EP15-XL2

EP14-XL1

EP15-XL1

XL40

Cleaning and filling

Filling and venting the brine system

Caution

Because the temperature of the brine system

varies depending on the heat source, the 5.1.7

“br pmp al set.” menu must be set to a suitable

value.

1. Use filling pump LK Pumpmobil FSB 30, or equivalent,

in this procedure.

LK Pumpmobil FSB 30

5

4

1

2

3

6

Connection hose, return, 3 m

1.

Mixing vessel, 30 l

2.

Connection hose, supply, 3 m

3.

Pressure/centrifugal pump

4.

Valve screw, pump

5.

Filter/strainer

6.

GreenMaster-HP

Chapter 6 |

Commissioning and adjusting

34