NFO

Drives

AB

2021

201013

‐

2

Operating

and

Installation

Manual

42

whatever setpoint is available from the terminals (e.g. analog input, selected fix frequencies, etc), and for run

command 101h the setpoint is taken from Input Frequency Setpoint register (when in Frequency mode), or Input

Speed Setpoint register (when in Speed mode).

To setup inverter for automatic stop if communication is lost, it’s possible to use the serial timeout parameter, see

corresponding paragraph in section 5.

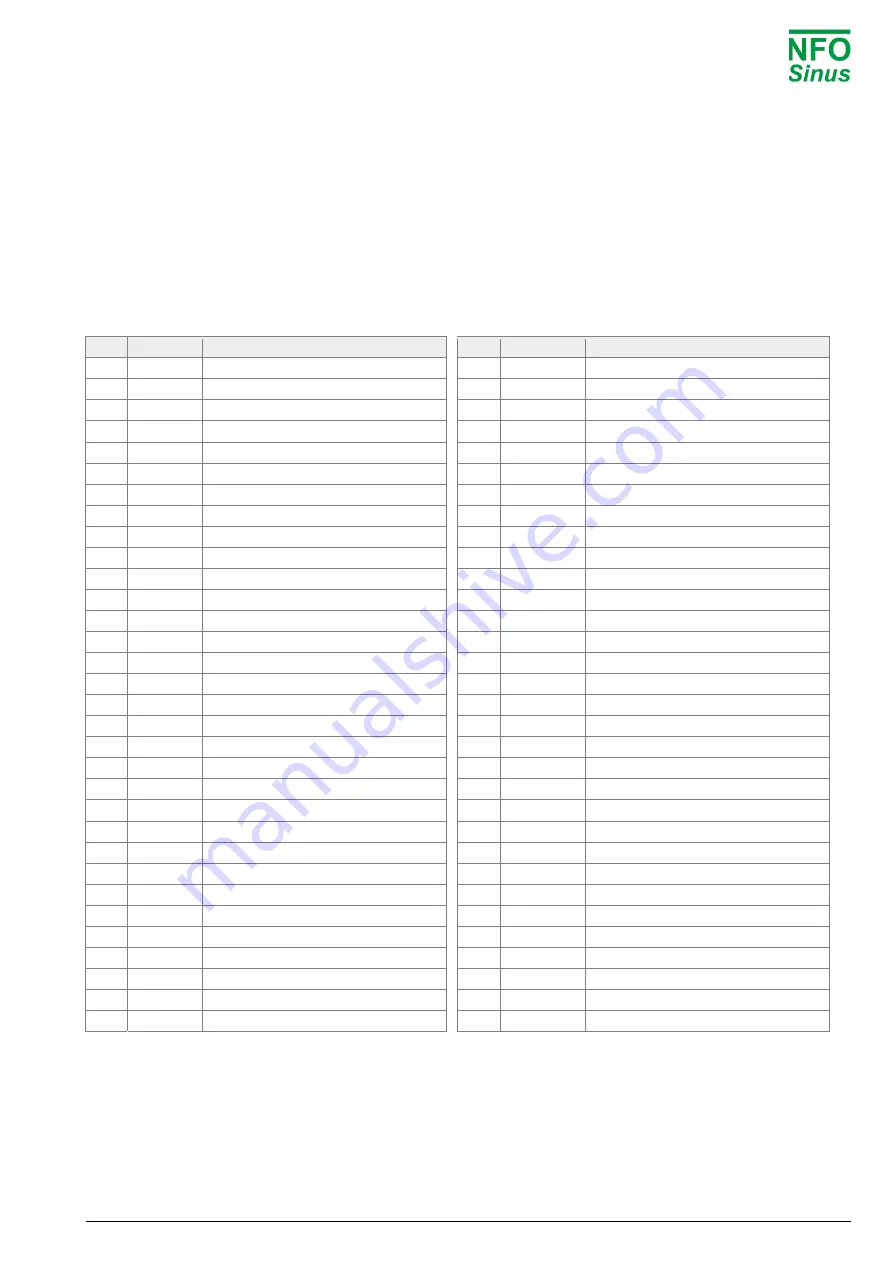

Status from inverter is reported in parameter Inverter status which can be read from Modbus register addresses

02A4h and 02A5h. Both will reply the same status code, but reading the former will also trigger an acknowledge of

alarm or fault condition, if such is active. Table below shows code, corresponding text shown on inverter display,

and a short description. The codes in

italic

are merely status, while other codes indicate an alarm or fault condition.

Code

Text

Description

Code

Text

Description

0

Erased

Error

log

was

erased

32

Decel

Inverter

is

decelerating

1

GND

Fail

R

Ground

fail

detected

during

run

33

Ext

Stby

Inverter

is

ready

for

run

cmd

in

Auto

mode

2

AC

Fail

Mains

power

error

34

Ext

Run

Inverter

is

running

in

Auto

mode

3

Temp

Hi

Too

high

temperature

on

heat

sink

35

Ext

Acc

Inverter

is

accelerating

in

Auto

mode

4

PTC

Temp

Motor

temperature

sensor

trip

36

Ext

Ret

Inverter

is

decelerating

in

Auto

mode

5

Overload

Electronic

motor

overload

trip

37

Bus

Stby

Inverter

is

ready

for

run

cmd

in

Bus

mode

6

Ain

Fail

Analog

input

out

of

range

38

Bus

Run

Inverter

is

running

in

Bus

mode

7

DC

Low

Internal

undervoltage

warning

39

Bus

Acc

Inverter

is

accelerating

in

Bus

mode

8

DC

High

Internal

overvoltage

warning

and

trip

40

Bus

Ret

Inverter

is

decelerating

in

Bus

mode

9

GND

Fail

S

Ground

fail

detected

during

stop

41

PI

Reg

Process

regulator

is

activated

at

terminal

10

Imagn

Low

Magnetization

current

too

low

or

too

high

42

Calibrating

Calibrate

procedure

is

ongoing

11

Cur

Low

Output

current

too

low

43

Calibr

Done

Calibrate

procedure

finished

12

Cur

High

Output

current

too

high

44

BasicTun

Ok

Basic

tuning

finished

13

Run

Fail

Locked

rotor

/

unable

to

control

motor

45

Full

Tun

Ok

Full

tuning

finished

14

Sio

Fail

Serial

communication

timeout

46

RsMeas

Ok

Stator

resistance

measurement

finished

15

Bus

Fail

Fieldbus

communication

timeout

47

ParCalc

Ok

Parameter

calculation

finished

16

Tun

Fail

P

Tuning

error,

parameter

value

48

Short

Circ

Short

circuit

error

detected

17

Tun

Fail

M

Tuning

error,

measurement

49

DC

Low

Trip

Internal

undervoltage

trip

18

RsMeasFail

Tuning

error,

stator

resistance

50

SampleTime

Internal

error,

measurement

sample

time

19

TuneCnvFail

Tuning

error,

calculation

51

Motor

Volt

Voltage

detected

on

motor

terminals

20

Dsp

ComErr

Internal

error,

communication

52

Unused

Reserved

for

future

use

21

Cop

Restrt

Internal

error,

restart/reboot

53

Not

Tuned

Tuning

has

not

been

performed

22

Dsp

SysErr

Internal

error,

measurement

circuits

54

Delay

Run

Inverter

will

start

after

run

delay

time

23

Cop

ComErr

Internal

error,

communication

55

DC

Low

Ctrl

Internal

undervoltage

regulation

active

24

Stop

Inverter

is

stopped

56

DC

High

Ctrl

Internal

overvoltage

regulation

active

25

Wait

Inverter

is

waiting

to

become

ready

57

Fact

Reset

Parameters

was

reset

to

factory

default

26

Brake

Ch

Brake

chopper

is

operating

58

Cop

FwUpdt

Firmware

update

of

co

‐

processor

27

Cur

Limit

Current

limit

has

been

reached

59

Dsp

FwUpdt

Firmware

update

of

DSP

28

Tuning

Tuning

is

ongoing

60

Gui

FwUpdt

Firmware

update

of

GUI

29

Sleep

Inverter

has

entered

sleep

mode

61

Unused

Reserved

for

future

use

30

Final

Freq

Inverter

has

reached

final

frequency

62

Unused

Reserved

for

future

use

31

Accel

Inverter

is

accelerating

63

Unused

Reserved

for

future

use

6.1.3 Control inverter using DriveControl/DriveStatus

As an alternative to the MODE/SMODE method, it’s also possible to control the inverter in a fashion more similar to

controlling from Profibus/Profinet, using bit field registers for control and status. When using Drive control register,

the inverter takes its setpoint from terminals (e.g. analog) or whatever setpoint is selected using other parameters.

3006469-2022-04