MAN-0093 Rev 0 Oxygen Sensor

June 2008

Net Safety Monitoring Inc.

8

SECTION 1: Plan

1.1 Locate Sensor

Prior to the installation process, a location plan for placing the sensor should be developed. Although there are

no absolute rules determining the quantity of detectors or location of a sensor, the following points should be

considered when planning the installation.

•

Carefully locate the sensor in an area where gases may potentially accumulate. (Remember, light gases

tend to rise and heavy gases tend to accumulate in low areas).

•

Use redundant systems to enhance protection and reliability.

•

Consider the air movement patterns within the facility.

•

Consider the construction of the facility such as trenches where heavy gases or peaks where light gases,

may accumulate.

•

Seek advice from experts knowledgeable about the primary gas to be detected.

•

Use common sense and refer to the regulatory publications that discuss guidelines for your industry.

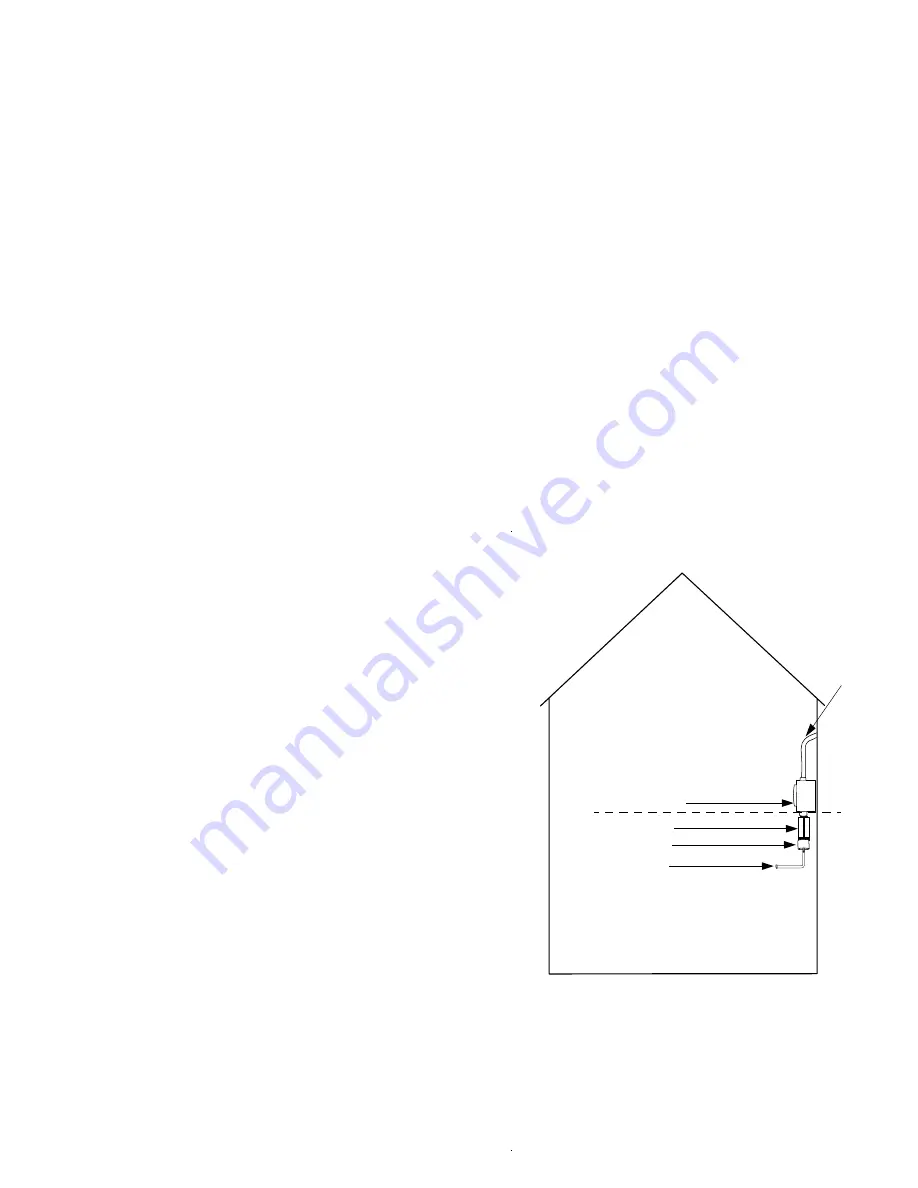

1.2 Sensor Non-Separated

The sensor is attached directly to a transmitter and located in the appropriate location for detecting the gas in

question.

Figure 3: Locating Sensor

1.3 Sensor Separated

Locate the sensor separate from a transmitter using a

‘junction box / separation kit’. The transmitter is located

near eye-level for easy access and the sensor is located

where the gas is likely to accumulate. A calibration cup is

clipped onto the bottom of the sensor housing and the

calibration tubing is attached to the calibration cup and

runs to a convenient place for applying calibration gas(air)

eliminating the need to access the sensor directly.

To compensate for distance when remotely calibrating, in

separation orientation, decrease the tubing diameter or

increase the calibration gas flow rate between the gas

canister and sensor. On initial install, always confirm

tubing run is not affecting calibration. Calibrate the sensor

using tubing run and then confirm readings directly at

sensor by applying calibration gas (air) and comparing the

output results. They should be accurate to the calibration

gas concentration used.

Sensor

Conduit to

Controller

Apply Calibration Gas

Controller

Calibration Cup

About

eye

level