45

EN

M1.1.HB250CF.NLFREN - 05012018

5 Machine structure and drive principle

5�1 Machine structure

This machine is made of column, carriage, lifting arm, spindle parts, safety lock device, oil cylinder, power unit, oil hose,

control box and electric wire. Mechanical lock and hydraulic lock double safety device ensure its security.

U

U

S

S

E

E

R

R

’

’

S

S

M

M

A

A

N

N

U

U

A

A

L

L

- 10 -

clear of the electrical control panel.

Risks related to appropriate lighting

The operator and the maintenance fitter must be able to assure that all the areas of the lift are properly and

uniformly illuminate compliance with the laws in force in the place of installation.

During up and down operations, the operator should continually observe the lift and can operate it only in the

position of operator. When lifting and lowering the vehicle, the cushion needs being put in the bottom of chassis.

The handling of safety devices is strictly forbidden. Never exceed the maximum carrying capacity of the

lift, make sure the vehicles to be lifted have no load.

6. Machine structure and drive principle

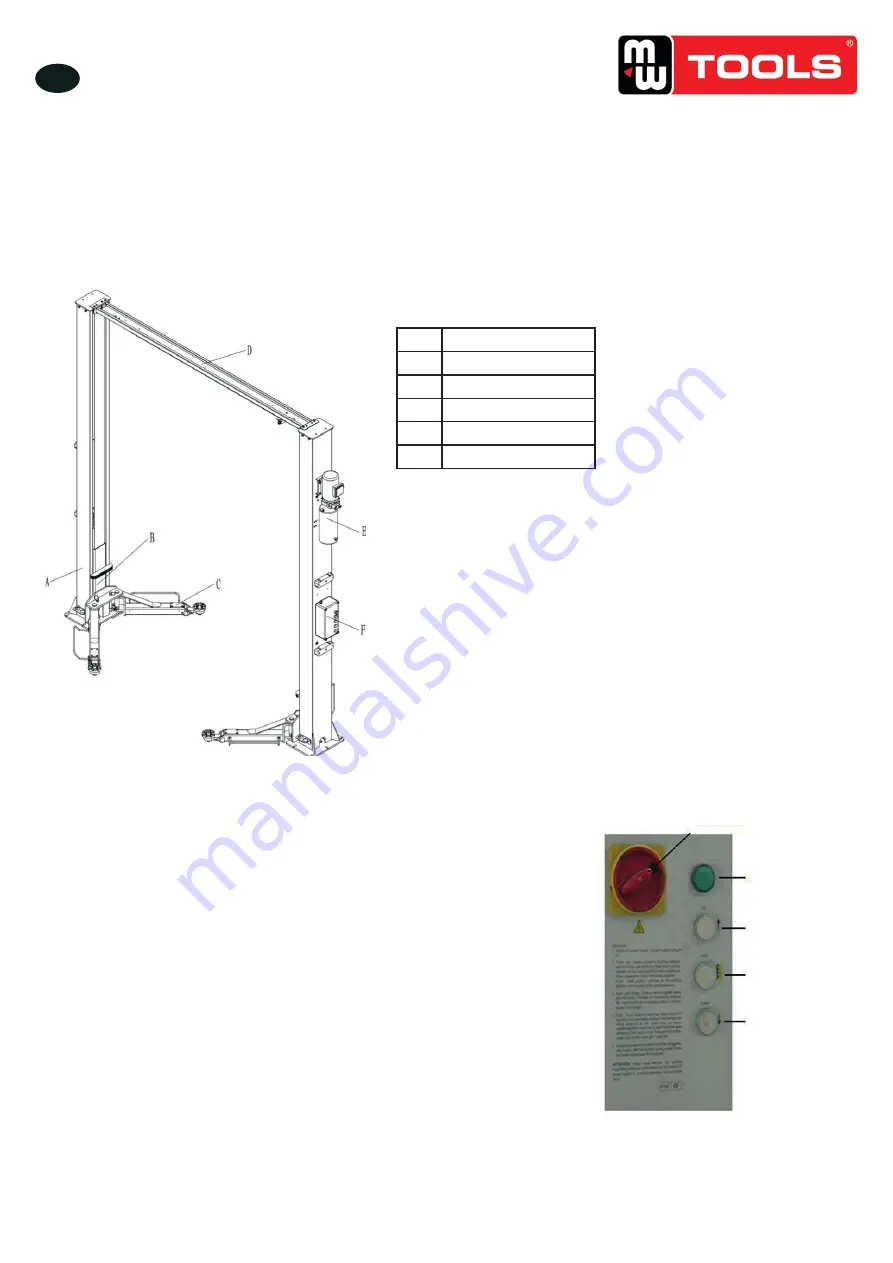

6.1 machine structure

:

-This machine is made of column, carriage, lifting arm, spindle parts, safety lock device, oil cylinder, power unit, oil

hose, control box and electric wire. mechanical lock and hydraulic lock double safety device ensure its security.

Instruction of each part

6.2 Drive principle

:

-

Press button “UP”, the contactor and motor work. Motor drives the gear pump, the hydraulic oil goes through the

one-way valve, oil hose finally reach the in the downward cavity of oil cylinder. The piston rod is pushed by the oil

A

Column

B

Carriage

C

Lifting arm

D

top beam

E

Power unit

F

Control box

Picture 5

Table 5

A

Column

B

Carriage

C

Lifting arm

D

Top beam

E

Power unit

F

Control box

Picture 4

Table 3

5�2 Drive principle

• Press button “UP”, the contactor and motor work. Motor drives the gear pump,

the hydraulic oil goes through the one-way valve, oil hose finally reach the in the

downward cavity of oil cylinder. The piston rod is pushed by the oil pressure. The

oil cylinder drives the lifting arm synchronously with the steel cable and roller

wheel and chain.

• To do the vehicle maintenance, operators press the “LOCK” button, the lowering

solenoid valve works and the electromagnets do not work when the carriage is

locked.

• To lower the lift, press the “DOWN” button, the time relay works, the lift raises

for 2-3 seconds and lowering solenoid valve works at the same time. The weight

of vehicle and lift extrude the hydraulic oil into the oil tank. Finish the lowering

operation.

U

U

S

S

E

E

R

R

’

’

S

S

M

M

A

A

N

N

U

U

A

A

L

L

- 11 -

pressure. The oil cylinder drives the lifting arm synchronously with the steel cable and roller wheel and chain.

. W

hen do the vehicle maintenance, operators press the “LOCK” button, the lower solenoid valve works and the

electromagnets do not work when the ca

rriages is locked. When lower the lift, press the “DOWN” button, the time

relay works, the lift raises for 2-3 seconds and lower solenoid valve works at the same time. The weight of vehicle

and lift extrude the hydraulic oil into the oil tank. Finish the lowering operation.

Picture 6

7. Installation

7.1 Installation requirement

-Two post lift must keep install under the safe distance requirement from the wall, column and other equipment.

Minim distance from wall is 800mm, consider the urgency situation and convenience work, the distance of exit

passageway should considered having enough rooms.

Please make sure there is power supply for the control unit.

The indoor height should not be less than 4500mm.

Indoor ground is available for installation, only the ground level meets the installation requirement and have enough

endurance capacity (concrete intensity must be higher than 21MPa, concrete thickness must reach 300mm and

above), otherwise, please pour concrete 1200 * 4000mm in installation space, thickness must reach 300mm and

above.

Table 6

Picture 7

A

Concrete thickness must reach 300mm and above

B

Side- hole to the concrete edge must reach 150mm

C

Machine baseboard installation distance

Main switch

Power indicator

“RISING” button

“LOCKING” button

“FALLING” button

Picture 5

copyrighted

document

- all

rights

reserved

by

FBC