11

NL

M1.1.HB250CF.NLFREN - 05012018

U

U

S

S

E

E

R

R

’

’

S

S

M

M

A

A

N

N

U

U

A

A

L

L

- 13 -

7.3 Installation

Column installation

a. Set up the column

set up the installed main and sub columns on the concrete foundation, with distance at 2680mm which is suitable to

install the oil hose cover plate, make sure the two columns are in same level.(refer below picture).

b. Install the expansion bolt

The expansion bolt must work after finished the maintenance of the concrete foundation, otherwise, it will affect

the locking quality.

-Adjust the position & vertical degree of the two columns.

-Use a hammer clip with

φ

18mm impact bit(the length of the bit

≥180mm )

drill the hole from the base plate hole till

depth 160MM, and clean the hole with dust cleaner

- Use the light hammer to knock the expansion bolts to the 10 holes (no need to insert the center expansion nail, fix

it after finished the level adjustment)

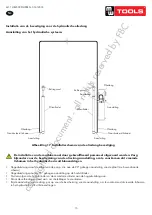

Picture 9 picture 10 picture 11

Picture 12 picture 13

c. Level adjustment

- Use a transparent horizontal tube or gradienter to exam the all around level of the master & vice column, if level

degree is no problem, insert the center expansion nail, heavy hammer knocks the center expansion nail, tighten the

nuts after finished to install the top beam and the master & vice column is still in level degree.

If the concrete foundation is under the maintenance, please do not knock in the center expansion bolt. The

space between the base plate and ground must fill with cement mortar after adjust the level degree

.

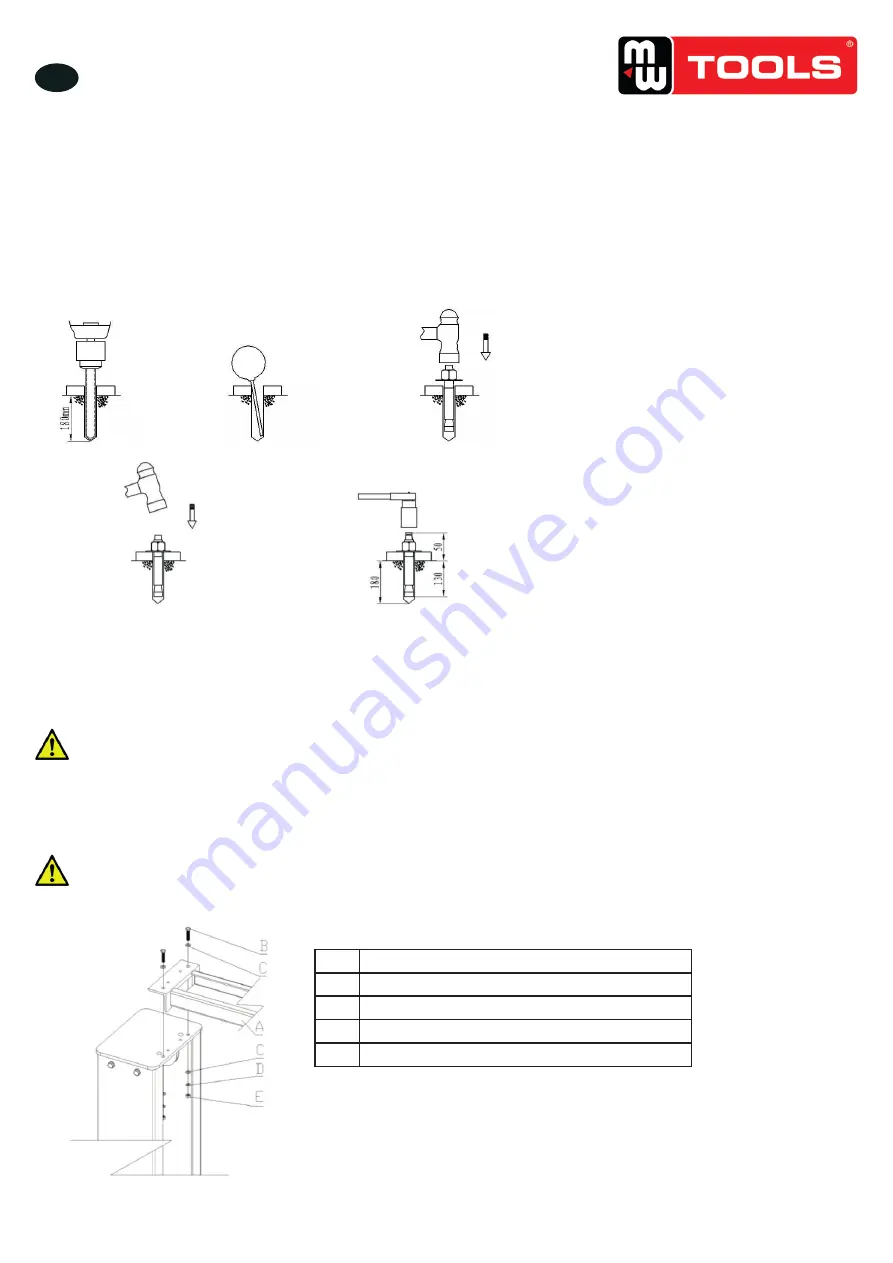

d. Top beam installation

- After raised the two columns stand up, put the top beam on the top of the two columns with crane and use bolts to

fix it.

ATTENTION:pay attention to the top beam while installating it for it might drop from middle-air and do harm to

person.

A

top beam

B

M8×35 full thread hex flanges bolt

C

φ8 flat washer

D

φ8 spring washer

E

φ8

nuts

2. Nivellering:

- Gebruik een transparante buis of een waterpas om het niveau rondom de kolommen te bekijken. Als het correct is, sla de

middenspijker met de zware hamer in. Bevestig vervolgens de moeren om de bovenbalk te installeren.

Als de betonbasis niet vlak is, sla de centrale expansiebout niet in� De ruimte tussen de basisplaat

en de vloer moet met mortel ingevuld worden, na het aanpassen van de horizontaliteit�

3. Installatie van de bovenbalk:

- Na de installatie van beide kolommen, plaats de bovenbalk op de kolommen met een kraan, en bevestig de balk met

bouten.

AANDACHT!

Pas op voor de bovenbalk bij de installatie, deze kan neervallen en iemand verwonden�

Installeer de expansiebouten:

- De expansiebouten moeten na het uitharden van de betonvloer geplaatst worden, anders zal de kwaliteit van de

bevestiging beïnvloed worden.

- Pas de positie en de verticaliteit van beide kolommen aan.

- Gebruik een boorhamer met een slagbit van 18 mm (lengte van de slagbit ≥180 mm). Boor een gat van 160 mm vanaf

de basisplaat en reinig het gat met een stofzuiger.

- Gebruik een lichte hamer om de expansiebouten in de 9 gaten in te slaan (geen noodzaak om de midedenspijker in te

slaan, bevestig deze na de nivellering).

U

U

S

S

E

E

R

R

’

’

S

S

M

M

A

A

N

N

U

U

A

A

L

L

- 13 -

7.3 Installation

Column installation

a. Set up the column

set up the installed main and sub columns on the concrete foundation, with distance at 2680mm which is suitable to

install the oil hose cover plate, make sure the two columns are in same level.(refer below picture).

b. Install the expansion bolt

The expansion bolt must work after finished the maintenance of the concrete foundation, otherwise, it will affect

the locking quality.

-Adjust the position & vertical degree of the two columns.

-Use a hammer clip with

φ

18mm impact bit(the length of the bit

≥180mm )

drill the hole from the base plate hole till

depth 160MM, and clean the hole with dust cleaner

- Use the light hammer to knock the expansion bolts to the 10 holes (no need to insert the center expansion nail, fix

it after finished the level adjustment)

Picture 9 picture 10 picture 11

Picture 12 picture 13

c. Level adjustment

- Use a transparent horizontal tube or gradienter to exam the all around level of the master & vice column, if level

degree is no problem, insert the center expansion nail, heavy hammer knocks the center expansion nail, tighten the

nuts after finished to install the top beam and the master & vice column is still in level degree.

If the concrete foundation is under the maintenance, please do not knock in the center expansion bolt. The

space between the base plate and ground must fill with cement mortar after adjust the level degree

.

d. Top beam installation

- After raised the two columns stand up, put the top beam on the top of the two columns with crane and use bolts to

fix it.

ATTENTION:pay attention to the top beam while installating it for it might drop from middle-air and do harm to

person.

A

top beam

B

M8×35 full thread hex flanges bolt

C

φ8 flat washer

D

φ8 spring washer

E

φ8

nuts

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

A

Bovenbalk

B

Flensbout met voldraad M8x35

C

Sluitring φ 8

D

Veerring φ 8

E

Moer φ 8

Tablel 5

Afbeelding 12

copyrighted

document

- all

rights

reserved

by

FBC