10/10/02 M1-4_EN

ENGLISH

ENGLISH

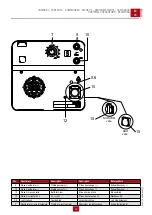

1

2

16

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

17

3

4

5

6

6

7

8

9

10

11

12

13

12a

12b

12c

13

14

13a

13b

13c

13a

13b

13c

14

14a

14b

14c

14a

14b

14c

9

15

Any of our product is labelled with CE marking attesting its conformity to appliable directives and also the fulfillment of safety

requirements of the product itself; the list of these directives is part of the declaration of conformity included in any machine

standard equipment.

Here below the adopted symbol:

CE marking is clearly readable and unerasable and it can be either part of the data-plate.

REV

.7-02/18

M

1.4.2

CE MARKING

ENGINE DRIVEN WELDER

Furthermore, on each model it is shown the noise level value; the symbol used is the following:

The indication is shown in a clear, readable and indeleble way on a sticker.

1. Manufacturer name or brand

2. Year of production

3. Engine Driven Welder model

4. Serial number | registration number

5. Reference to the standard confir

-

ming that the Engine Driven Welder

complies with its requirements

6. Welding process symbol

7. Symbol for Engine Driven Welders

which can be used an environment

with increased risk of electric shock.

8. Welding current symbol

9. OCV value (Rated no-load voltage)

or adjustment range between mini-

mum and maximum value

10. Reduced rated no-load voltage in

case of a voltage reducing device

(VRD)

11. Maximum and minimum welding

current values and relative voltage

value

12. Duty cycle symbol

12a. Duty cycle values

12b. Duty cycle values

12c. Duty cycle values

13. Rated welding current symbol

13a. Rated welding current values

13b. Rated welding current values

13c. Rated welding current values

14. Conventional load voltage symbol

14a. Welding voltage values

14b. Welding voltage values

14c. Welding voltage values

15. Auxiliary power supply symbol

16. Rated frequency

17. Power factor Cos

ϕ

18. Insulation class

19. Rated power (kVA/kW)

20. Rated voltage (V)

21. Rated current (A)

22. Rated power (kVA/kW)

23. Rated voltage (V)

24. Rated current (A)

25. Rated power (kVA/kW)

26. Rated voltage (V)

27. Rated current (A)

28. Engine symbol

29. Rated speed

30. Rated no-load speed

31. Rated idle speed

32. Engine maximum power

33. IP degree protection

34. Dry weight (kg)

5

Содержание MAGIC WELD 200

Страница 2: ......

Страница 33: ...11 01 01 Note NOTE 33...

Страница 34: ...11 01 01 Note NOTE 34...

Страница 35: ......