26/1

1/08 C0DN6000_EN

ENGLISH

ENGLISH

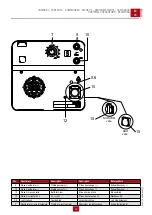

FIG. 1

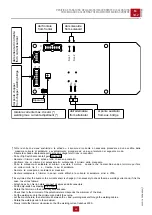

FIG. 2

M

34.1

USE AS A WELDER

REV

.0-12/19

AUTO IDLE

Operation

When the engine is switched on it immediately reaches a ma-

ximum speed of 3720 rpm for approximately 6/7 seconds for

easy start up, after which it automatically decreases and idles at

2650 rpm. It remains at this speed until current is drawn when

set to weld or auxiliary power.

When set to weld mode the machine reaches maximum engine

speed as soon as there is minimum contact between the tip of

the electrode and the piece to be welded and also when set to

generation drawing a minimum of 250 – 300 W

The machine returns to minimum 6/7 seconds later if power is

not drawn during welding or generation.

Checking and adjusting idling speed

- Check idling speed when COLD;

- When the engine is switched on it reaches maximum speed;

after 6/7 seconds it decreases automatically to idle. Check

the speed when the engine idles;

- The idling speed corresponds to 47-50 Vdc at the welding

sockets or the equivalent at 2650 rpm.

Minimum welding voltage TOO LOW

- From Fig. 1 proceed as follows:

•

when the machine idles (engine cold)

•

Keep pin A locked (8 mm spanner) and unscrew nut B (7

mm spanner)

•

Again with pin A locked, turn nut C clockwise (7 mm spanner)

1 - 3 mm: The more it is extended the more the idle speed

increases

•

Tighten nut B on pin A and check the idling speed.

Minimum welding voltage TOO HIGH

- From Fig. 1 proceed as follows:

•

When the machine idles (engine cold)

•

Keep pin A locked (8 mm spanner) and unscrew nut B 1-3

mm (7 mm spanner)

•

Again with pin A locked, turn nut C anticlockwise (7 mm

spanner) until nut B touches pin A

•

Tighten nut B against pin A and check that the idling speed

is correct.

Adjusting the maximum engine speed

Calibration of maximum RPM (Revolutions Per Minute)

To check that the maximum engine RPM is correct, simply

measure that the welding tension with no-load (not under load)

at the maximum RPM must be between 69-71V.

Adjustment is made by the screw (A) Fig. 2.; first, however,

the accelerator lever lock nut must be loosened, then carry out

the adjustment, turning the screw (A) clockwise to reduce the

maximum and anti-clockwise to increase it. Once the calibration

has been carried out, re-tighten the accelerator lever lock nut.

21

Содержание MAGIC WELD 200

Страница 2: ......

Страница 33: ...11 01 01 Note NOTE 33...

Страница 34: ...11 01 01 Note NOTE 34...

Страница 35: ......