26/1

1/08 C0DN6000_EN

ENGLISH

ENGLISH

M

40.2

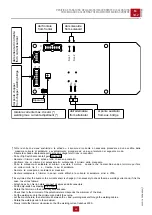

TROUBLE-SHOOTING

REV

.0-12/19

Problem

Possible cause

Solution

ENGINE

The motor does not start up,

or starts up and then stops

immediately

1) Engine switch (28) at position OFF

2) Lack of or insufficient oil in the motor

3) Faulty motor stopping device (oil-alert)

4) Lack of fuel in tank or fuel tap closed

5) Dirty or faulty spark plug

6) Cold motor

7) Other causes

1) Position switch to ON

2) Refill or top off

3) Replace

4) Refill the tank. Open the fuel tap

5) Clean or check and eventually replace

6) Hold down the CHOKE button, after start-up,

for a longer period of time

7) Consult the motor Operating Manual.

The motor does not accelerate.

Inconstant speed.

Too little power provided by

motor.

1) Air or fuel filter clogged

2) Bad gasoline

3) Overload

1) Check the air filter

2) Drain fuel tank and carburetor. Refuel with

fresh gasoline

3) Check the connected loads and if necessary

reduce

Other problems or inconve-

niences on the engine.

Consult the motor Operating Manual

WELDING CIRCUIT

No current under no-load con-

ditions in weld mode

1) Faulty welding control board

2) Faulty Hall sensor

3) Chopper welding bridge broken

4) Faulty alternator

1) Ask for intervention of Service Department

to replace the board.

2) Ask for intervention of Service Department

to replace the Hall sensor.

3) Ask for intervention of Service Department

to replace the Chopper Bridge.

4) Disconnect the welding and auxiliary power

cables. Use a voltmeter to check that there

is 48 Vac at the outputs in weld and appro-

ximately 145 Vac between the outputs in

generation. Carry out the check when the

engine idles (disconnect one of the two

wires to the solenoid).

Irregular or inconsistent wel-

ding current

1) Faulty welding control board

2) Faulty Hall sensor

3) Chopper bridge short circuit

1) Ask for intervention of Service Department

to replace the board.

2) Ask for intervention of Service Department

to replace the Hall sensor.

3) Ask for intervention of Service Department

to replace the Chopper Bridge.

Engine always at idle speed.

Engine always at maximum

speed

1) Faulty welding control board

2) Fault to the Auto Idle -

Economizer system

1) Ask for intervention of Service Department

to replace the board.

2) Check that the resistance of the solenoid

winding is approximately 10 ohm.

Replace.

Ask for intervention of Service Department.

25

Содержание MAGIC WELD 200

Страница 2: ......

Страница 33: ...11 01 01 Note NOTE 33...

Страница 34: ...11 01 01 Note NOTE 34...

Страница 35: ......