MOHAWK MODEL LMF-12, TP-15,TP-16 & TP-18

7

INSTALLATION INSTRUCTIONS

IMPORTANT

READ THIS MANUAL IN ITS ENTIRETY. BE FAMILIAR WITH PART NAMES AND HAVE A GOOD UNDERSTANDING

OF HOW THIS UNIT IS TO BE ASSEMBLED AND OF HOW INDIVIDUAL

PARTS OPERATE, BEFORE ASSEMBLING THE UNIT.

REFER TO ANSI/ALI ALIS, SAFETY REQUIREMENTS FOR INSTALLATION AND SERVICE OF AUTOMOTIVE LIFTS.

USING A CHALK LINE, LAYOUT THE FLOOR DIMENSIONS WHERE

THE UNIT WILL BE LOCATED.

REFER TO FIGURES 1 & 8

.

CUT THE SWING ARM BANDING AND REMOVE THE SWING

ARMS.

SECURE THE OVERHEAD LIFTING DEVICE TO THE MAIN SIDE

POST USING STRAPS OR CHAINS.

WARNING

•

EACH POST WEIGHS OVER 900 LBS. ERECT THE POSTS WITH

CHAINS AND STRAPS ATTACHED TO THE TOP OF THE POST.

DO NOT REMOVE THE CHAINS AND STRAPS UNTIL THE

POST HAS BEEN SECURED.

SEPARATE THE POSTS. REMOVE THE PARTS BOX, HYDRAULIC

LINES AND SUPPORTS. VERIFY PARTS BOX CONTENTS. IF

MISSING PARTS ARE NOTED, THEY CAN BE OBTAINED BY

CALLING 1-800-833-2006 OR BY CONTACTING YOUR LOCAL

MOHAWK DISTRIBUTOR.

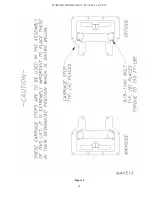

USING THE 5/8-INCH PACKING BOLTS, NUTS AND WASHERS,

ASSEMBLE THE CARRIAGE STOPS TO THE TOP OF THE MAIN

SIDE POST. TIGHTEN TO 150 FOOT POUNDS.

REFER TO FIGURE 2.

ERECT THE MAIN AND OFF SIDE POSTS TO THE UP-RIGHT

POSITION. ALIGN THE POST FOOTINGS TO THE CHALK LINE

LAYOUTS.

SECURE THE MAIN AND OFF SIDE POSTS TO THE BAY FLOOR

USING THE (16) 3/4 X 5 1/2 INCH WEJ-IT ANCHORS. REFER TO

“BEFORE DRILLING THE MOUNTING HOLES“ SECTION.

USING THE 5/8-INCH PACKING BOLTS, NUTS AND WASHERS,

ASSEMBLE THE CARRIAGE STOPS TO THE TOP OF THE OFF SIDE

POST. TIGHTEN TO 150 FOOT POUNDS.

REFER TO FIGURE 2.

ASSEMBLE THE TWO OVERHEAD HYDRAULIC LINES (FLAT ON

THE FLOOR) USING THE FOUR DOUBLE MALE UNIONS.

SEE

MAN501.

ASSEMBLE TWO OF THE DOUBLE LINE CLIPS TO THE CENTER

SPAN OF THE OVERHEAD LINES APPROXIMATELY 3 INCHES

FROM THE DOUBLE UNIONS.

ASSEMBLE THE TWO OVERHEAD LINE SUPPORT BRACKETS TO

THE TOP OF THE MAIN AND OFF SIDE POST.

ERECT THE OVERHEAD HYDRAULIC LINE ASSEMBLIES AND AIR

HOSE. ROUTE THE LINES THROUGH THE TOP OF EACH POST.

ASSEMBLE THE LINES TO THE HYDRAULIC CONNECTIONS AT

THE TOP OF EACH POST.

SECURE THE LINES TO THE OVERHEAD LINE SUPPORTS USING

THE DOUBLE LINE CLIPS PROVIDED.

REMOVE THE BREATHER PORT PLUG ON THE POWER UNITS

RESERVOIR AND DISCARD.

REFER TO FIGURE 11

.

VERIFY FLUID LEVEL. (1/2 IN. BELOW BREATHER PORT IN THE

POWER UNIT RESERVOIR WHEN BOTH CYLINDERS ARE FULLY

RETRACTED) INSTALL THE BREATHER CAP.

AT THIS TIME HAVE A QUALIFIED ELECTRICIAN

CONNECT THE POWER SUPPLY TO THE UNIT

CONNECT AN AIR SUPPLY TO THE REGULATOR NEAR THE

POWER UNIT. ADJUST THE REGULATOR TO 60-80 PSI. PRESS THE

LOCK RELEASE BUTTON AT THE AIR REGULAOR AND ENSURE

THAT LOCKS RELEASE AND THAT THERE ARE NO LEAKS IN THE

AIR SYSTEM.

ENGAGE THE UP BUTTON ON THE POWER UNIT AND RAISE THE

CARRIAGES APPROX. 3 FEET, OR TO A HEIGHT SUITABLE FOR

INSTALLING THE SWING ARMS.

REMOVE & REASSEMBLE THE FOUR SWING ARM RESTRAINTS

ONTO THE MAIN AND OFF SIDE CARRIAGES.

REFER TO MAN502.

LIFTING UP ON THE SWING ARM RESTRAINT. INSERT THE FOUR

SWING ARMS INTO THE CARRIAGES.

REFER TO MAN506.

ALIGN THE THROUGH HOLES IN THE CARRIAGES WITH THE

THROUGH HOLES IN THE SWING ARMS. SECURE THE SWING

ARMS TO THE CARRIAGES USING THE FOUR SWING ARM PINS

AND EIGHT NYLON LOCK NUTS.

PLACE THE FOUR LIFTING PADS INTO PLACE IN THE MOUNTING

HOLE AT THE END OF EACH SLIDER.

REFER TO MAN506.

Содержание LMF-12

Страница 26: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 19 Figure 1 ...

Страница 27: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 20 Figure 2 ...

Страница 28: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 21 Figure 3 ...

Страница 29: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 22 Figure 4a ...

Страница 30: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 23 Figure 4b ...

Страница 31: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 24 Figure 5 ...

Страница 32: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 25 Figure 6 ...

Страница 33: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 26 Figure 7 ...

Страница 34: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 27 Figure 8 ...

Страница 35: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 28 Figure 9 ...

Страница 36: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 29 Figure 10 ...

Страница 37: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 30 Figure 11 ...

Страница 38: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 31 Figure 12 ...

Страница 40: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 33 ...

Страница 41: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 34 ...

Страница 42: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 35 ...

Страница 43: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 36 ...

Страница 44: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 37 ...

Страница 45: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 38 ...

Страница 46: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 39 ...

Страница 47: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 40 ...

Страница 48: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 41 ...

Страница 49: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 42 ...

Страница 50: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 43 ...

Страница 51: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 44 ...

Страница 52: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 45 ...

Страница 53: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 46 ...

Страница 55: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 48 ...

Страница 56: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 49 ...

Страница 57: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 50 ...

Страница 58: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 51 ...

Страница 59: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 52 ...

Страница 60: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 53 ...

Страница 61: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 54 ...

Страница 62: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 55 ...

Страница 63: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 56 ...

Страница 68: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 61 ...

Страница 69: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 62 ...

Страница 70: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 63 ...

Страница 71: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 64 ...

Страница 72: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 65 ...

Страница 73: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 66 ...

Страница 74: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 67 ...

Страница 75: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 68 ...