5-565.1

14

air shutter adjustment

Proper operation provides a soft blue flame with a well-defined

inner core. A lack of primary air will reveal soft yellow-tipped

flames. Excess primary air produces short, well-defined flames

with a tendency to lift off the burner ports. For both natural

and propane gas, the air shutters can be adjusted to control

the burner flame height. The air shutters can be accessed by

reaching behind the gas valve in Figure 14.1. The larger models

may require the removal of the manifold (see Manifold Assembly

Removal).

natural gas flame control

Control of burner flames on duct furnaces utilizing natural gas

is achieved by resetting the primary air shutters (See Figure

48.4) to either increase or decrease primary combustion air.

Prior to flame adjustment, operate duct furnace for about fifteen

minutes. The main burner flame can be viewed after loosening

and pushing aside the gas designation disc on the side of the

burner box.

To increase primary air, loosen the air shutter set screws and

move the air shutters closer to the manifold until the yellow-

tipped flames disappear. (See Figure 48.4 for air shutter and

start-uP Procedure

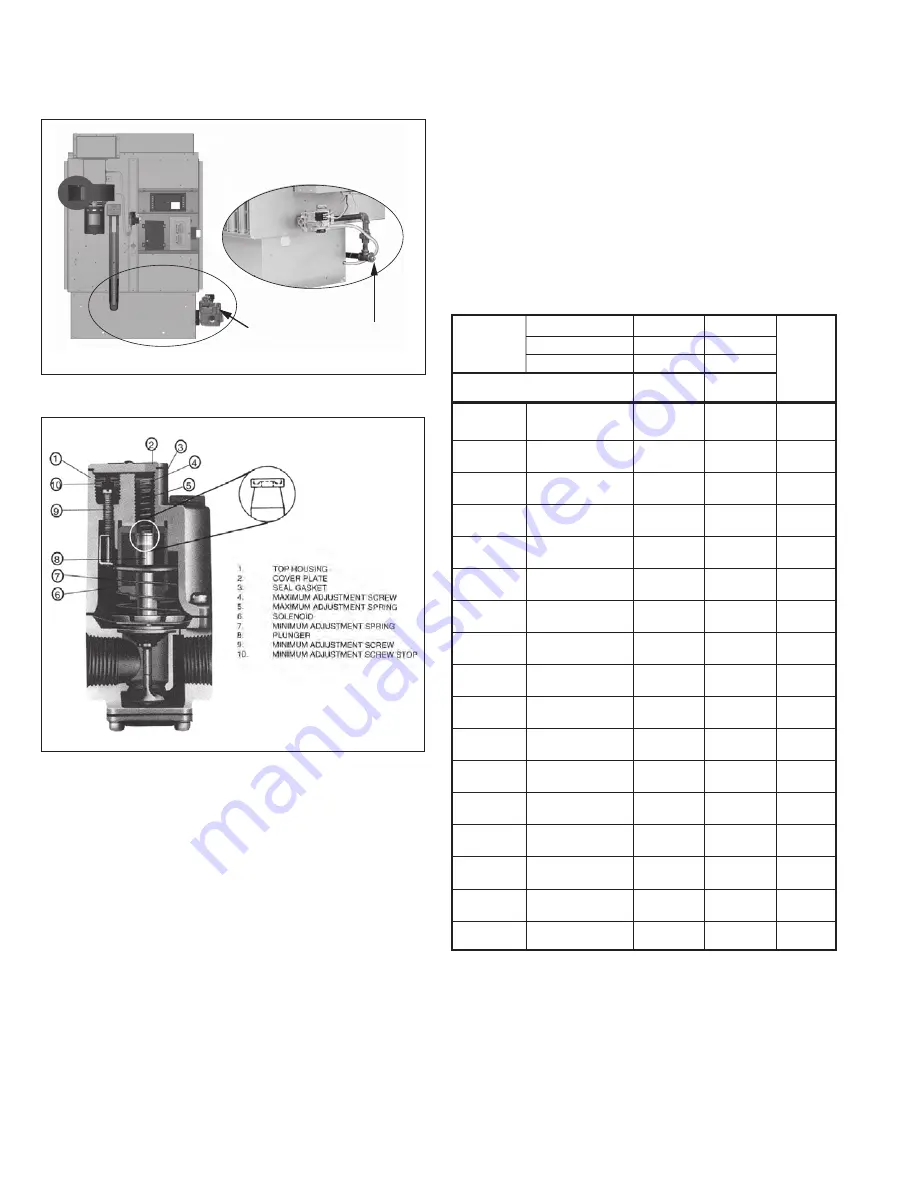

figure 14.1 - checking manifold Pressure with

“u” tube manometer

figure 14.2 - maxitrol modulating valve adjustments

heat exchanger support locations.) To decrease primary air,

move the air shutters away from the manifolds until flames

no longer lift from burner ports, but being careful not to cause

yellow tipping. Retighten set screws after adjustment.

Propane gas flame control

An optimum flame will show a slight yellow tip. Prior to flame

adjustment, operate furnace for at least fifteen minutes. Loosen

air shutter set screws and move the air shutters away from the

manifold to reduce the primary air until the yellow flame tips

appear. Then increase the primary air until yellow tips diminish

and a clean blue flame with a well defined inner cone appears.

model size

type of gas

natural

Propane

Btu/cu. ft.

1040

2500

specific gravity

0.60

1.53

High fire manifold Pressure

no. of

inches of Water column

3.5

10

orifices

Cfh

72.1

30.0

1

Orifice Drill Size

20

37

Cfh

96.1

40.0

2

Orifice Drill Size

30

45

Cfh

120.2

50.0

2

Orifice Drill Size

25

42

Cfh

144.2

60.0

3

Orifice Drill Size

30

45

Cfh

168.3

70.0

3

Orifice Drill Size

27

43

Cfh

192.3

80.0

3

Orifice Drill Size

23

40

Cfh

216.3

90.0

3

Orifice Drill Size

20

37

Cfh

240.4

100.0

4

Orifice Drill Size

25

42

Cfh

288.7

120.0

4

Orifice Drill Size

20

37

Cfh

336.5

140.0

6

Orifice Drill Size

27

43

Cfh

384.6

160.0

6

Orifice Drill Size

23

40

Cfh

240.4

➀

100.0

➀

4

Orifice Drill Size

25

42

Cfh

288.7

➀

120.0

➀

4

Orifice Drill Size

20

37

Cfh

336.5

➀

140.0

➀

6

Orifice Drill Size

27

43

Cfh

384.6

➀

160.0

➀

6

Orifice Drill Size

23

40

Cfh

336.5

➁

140.0

➁

6

Orifice Drill Size

27

43

Cfh

384.6

➁

160.0

➁

6

Orifice Drill Size

23

40

75

100

125

150

175

200

225

250

300

350

400

500

➀

600

➀

700

➀

800

➀

840

➁

➀

➀

➀

➀

➁

➁

960

➁

➀

Model contains 2 furnaces. Values shown are per furnace.

➁

Model contains 3 furnaces. Values shown are per furnace.

table 14.1 - manifold Pressure and gas consumption

Standard Controls

Premium Controls

Manifold Pressure Test Point