EN-2

Contents

Before installing the FTC2BR unit, make sure you read all the “Safety

precautions”.

Please report to your supply authority or obtain their consent before

connecting this equipment to the power supply system.

Warning:

Precautions that must be observed to prevent injuries or death.

Caution:

Precautions that must be observed to prevent damages to the unit.

After installation, perform the test run to ensure normal operation. Then explain

your customer the “Safety Precautions,” use, and maintenance of the unit based on

the information in the Operation Manual provided by local application manufacture.

Both the Installation Manual and the Operation Manual must be given to the user.

These manuals must always be kept by the actual users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels attached to the unit.

Warning:

• The unit must not be installed by the user. Ask an installer or an authorized

technician to install the unit. If the unit is installed improperly, electric

shock, or fire may be caused.

• For installation work, follow the instructions in the Installation Manual and

use tools and pipe components specifically made for use with refrigerant

specified in the outdoor unit installation manual.

• The unit must be installed according to the instructions in order to mini-

mize the risk of damages by earthquakes, typhoons, or strong winds.

Improperly installed unit may fall down and cause damages or injuries.

• The unit must be securely installed on a structure that can sustain its weight.

If the unit is mounted on an unstable structure, it may fall down and cause

damages or injuries.

• All electric work must be performed by a qualified technician according to

local regulations and the instructions given in this manual. The unit must

be powered by dedicated power lines and the correct voltage and circuit

breakers must be used. Power lines with insufficient capacity or incorrect

electrical work may result in electric shock or fire.

• Only the specified cables can be used for wiring. Connections must be

made securely without tension on the terminals. If cables are connected or

installed improperly, It may result in overheating or fire.

• Terminal block cover panel of the unit must be firmly fixed. If the cover

panel is mounted improperly, dust and moisture may enter the unit, and it

may cause electric shock or fire.

• Make sure to use accessories authorized by Mitsubishi Electric and ask

an installer or an authorized technician to install them. If accessories are

improperly installed, it may cause electric shock, or fire.

• Do not remodel the unit. Consult an installer for repairs. If alterations or

repairs are not performed correctly, it may cause electric shock or fire.

• The user should never attempt to repair the unit or transfer it to another

location. If the unit is installed improperly, it may cause electric shock or

fire. If the FTC2BR unit needs to be repaired or moved, ask an installer or

an authorized technician.

• During installing a heat pump system, keep water from splashing on the

FTC2BR unit.

• When installing sensors and parts, do not expose the terminals.

1.1. Before installation (Environment)

Caution:

• Do not install the FTC2BR unit in outdoor location as it is designed for

indoor installation only. Otherwise electric shock or breakdown may be

caused by water drop, wind or dust.

• Do not use the unit in an unusual environment. If the FTC2BR unit is installed

or exposed to steam, volatile oil (including machine oil), or sulfuric gas, or

exposed to briny air, the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced,

flow, or accumulate. If combustible gas accumulates around the unit, it may

cause fire or explosion.

• When installing the unit in a hospital or in a building where communica-

tions equipment are installed, you may need to take measure to noise and

electronic interference. Inverters, home appliances, high-frequency medical

equipment, and radio communications equipment can cause the FTC2BR

unit to malfunction or to breakdown. At the same time, the noise and elec-

tric interference from the FTC2BR unit may disturb the proper operation of

medical equipment, and communications equipment.

1.2. Before installation or relocation

Caution:

• Be fully careful when moving the units. Do not hold the packaging bands.

Wear protective gloves to unpack and to move it, in order to avoid your

hands be injured by parts.

1.3. Before electric work

Caution:

• Be sure to install a circuit breaker. If it is not installed, there may be a risk

to get an electric shock.

• For the power lines, use standard cables of sufficient capacity. Otherwise,

it may cause a short circuit, overheating, or fire.

• When installing the power lines, do not apply tension to the cables. The

cables may be cut or overheated resulting in a fire.

• Make sure to ground the unit. Do not connect the ground wire to gas or

water pipes, lightning rods, or telephone grounding lines. If the unit is not

properly grounded, there may be a risk to get an electric shock.

• Make sure to use circuit breakers (ground fault interrupter, isolating switch

(+B fuse), and molded case circuit breaker) with the specified capacity. If

the circuit breaker capacity is larger than the specified capacity, break-

down or fire may result.

1.4. Before starting the test run

Caution:

• Turn on the main power switch of the outdoor unit more than 12 hours

before starting operation. Starting operation immediately after turning on

the power switch can severely damage the internal parts. Keep the main

power switch turned on during the operation period.

• Before starting operation, check that all protective parts are correctly in-

stalled. Make sure not to get injured by touching high voltage parts.

• Do not touch any switch with wet hands. There may be a risk to get an

electric shock.

• After stopping operation, make sure to wait at least 5 minutes before turn-

ing off the main power. Otherwise, it may cause breakdown.

• Be sure to safely dispose of the packaging materials. Packaging materials,

such as nails and other metal or wooden parts may cause injuries.

• Do not wash the FTC2BR unit. You may receive an electric shock.

1. Safety precautions .....................................................................................2

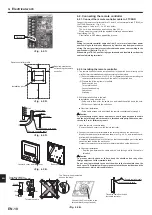

2. Installing the FTC2BR unit ........................................................................3

3. System ......................................................................................................4

4. Electrical work .........................................................................................10

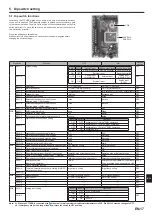

5. Dip switch setting ....................................................................................17

6. Before test run .........................................................................................22

7. Remote controller operation ....................................................................23

8. Troubleshooting .......................................................................................29

9. Supplementary information .....................................................................31

Local application factors ................................................................................32

1. Safety precautions

“FTC2BR” is the abbreviation of “Flow Temperature Controller 2BR”, which is described as “FTC2BR” in this manual.

Mitsubishi Electric is not responsible for the failure of locally supplied parts.

1.5. Electric booster and Immersion heaters

Warning:

• FTC2BR has signal outputs for booster heaters however it can not isolate

power to them in the event of overheating. All electrical heaters used on

the water circuit must have

a) A thermostat to prevent overheating

b) A non-self resetting thermal mechanism to prevent overheating

en

Содержание PAC-IF033B-E

Страница 35: ......