citors that discharge through the coils of

the combination magnets. C6 discharges

through the coil of the mirror-release

combination magnet M1; C5 discharges

through the coil of the diaphragm-control

combination magnet M2.

As yet, you can't reach the combina

tion magnets. So, if there's a problem in

either the mirror-release circuit or in the

diaphragm-control circuit, you may have

to remove the front-plate assembly.

However, you can troubleshoot both cir

cuits and pinpoint the malfunction w ith

o u t further disassembly. And, if you find

that the problem is on the circuit board,

Fig. 8, you can make the repair w itho u t

disassembling the camera any further.

The tw o combination magnets have

very similar circuits. Fig. 10 shows the cir

cuit for the mirror-release magnet M1.

Transistor T6 serves as a switch between

the mirror-release capacitor C6 and the coil

of the mirror-release magnet M1. Turning

on T6 allows the capacitor to discharge

through the coil. The spurt of current

causes the armature of M1 to jump away

from the core and release the mirror.

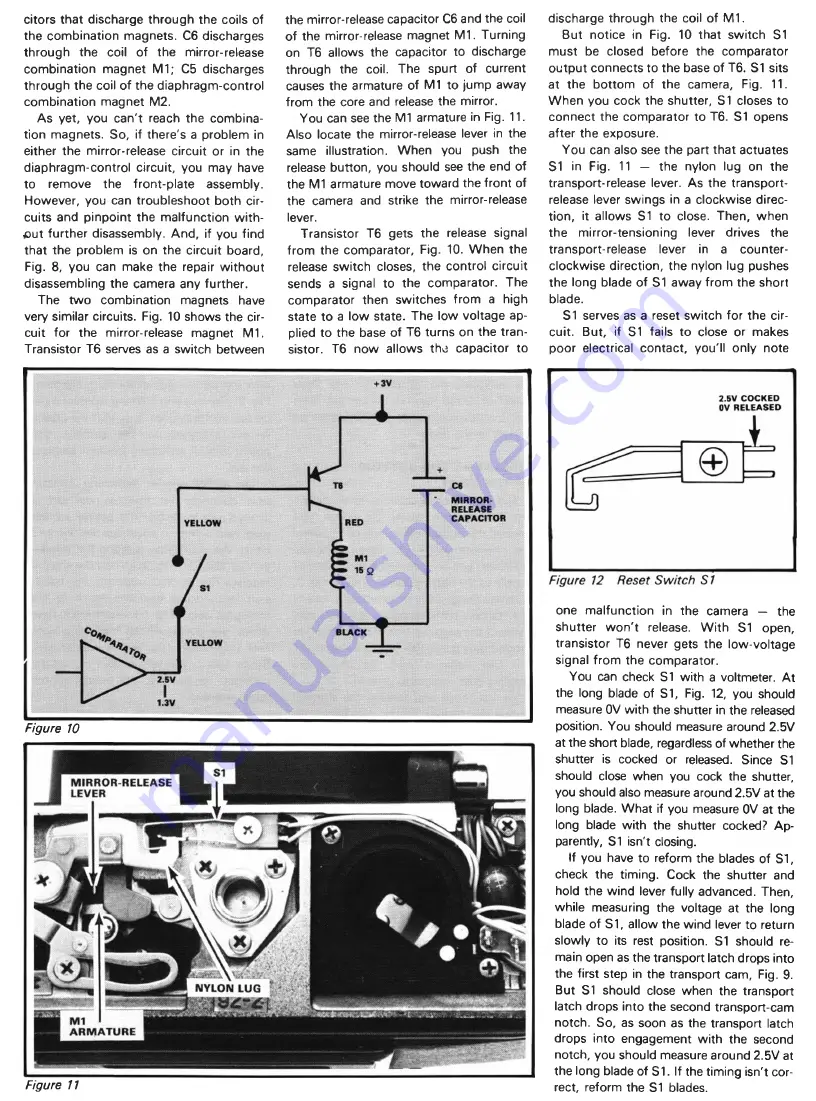

You can see the M1 armature in Fig. 11.

Also locate the mirror-release lever in the

same illustration. When you push the

release button, you should see the end of

the M1 armature move toward the front of

the camera and strike the mirror-release

lever.

Transistor T6 gets the release signal

from the comparator, Fig. 10. W hen the

release switch closes, the control circuit

sends a signal to the comparator. The

comparator then switches from a high

state to a low state. The low voltage ap

plied to the base of T6 turns on the tran

sistor. T6 now allows the capacitor to

discharge through the coil of M1.

But notice in Fig. 10 that switch S1

must be closed before the comparator

output connects to the base of T6. S1 sits

at the bottom of the camera, Fig. 11.

W hen you cock the shutter, S1 closes to

connect the comparator to T6. S1 opens

after the exposure.

You can also see the part that actuates

S1 in Fig. 11 — the nylon lug on the

transport-release lever. As the transport-

release lever swings in a clockwise direc

tion, it allows S1 to close. Then, when

the mirror-tensioning lever drives the

transport-release lever in a counter

clockwise direction, the nylon lug pushes

the long blade of S1 away from the short

blade.

S1

serves as a reset switch fo r the cir

cuit. But, if S1 fails to close or makes

poor electrical contact, you'll only note

Figure 10

Figure 11

one malfunction in the camera — the

shutter w o n 't release. W ith S1 open,

transistor T6 never gets the low-voltage

signal from the comparator.

You can check S1 with a voltmeter. A t

the long blade of S1, Fig. 12, you should

measure 0V w ith the shutter in the released

position. You should measure around 2.5V

at the short blade, regardless of whether the

shutter is cocked or released. Since S1

should close when you cock the shutter,

you should also measure around 2.5V at the

long blade. W hat if you measure 0V at the

long blade with the shutter cocked? Ap

parently, S1 isn't closing.

If you have to reform the blades of S I,

check the timing. Cock the shutter and

hold the wind lever fully advanced. Then,

while measuring the voltage at the long

blade of S1, allow the wind lever to return

slowly to its rest position. S1 should re

main open as the transport latch drops into

the first step in the transport cam, Fig. 9.

But S1 should close when the transport

latch drops into the second transport-cam

notch. So, as soon as the transport latch

drops into engagement w ith the second

notch, you should measure around 2.5V at

the long blade of S1. If the timing isn't cor

rect, reform the S1 blades.