may allow the piston to move too quickly.

Since the memory time lag is then too

short, the owner gets inaccurate or erratic

exposures at auto. Yet,

at normal

altitudes, the camera tests perfectly.

Dirt in the air cylinder can also cause

problems — even a failure of the mirror to

release. You can remove the air cylinder

for cleaning w itho u t taking out the mirror

cage. Just remove the tw o screws hold

ing the air cylinder; reach the screws

through the cutout at the side of the lens

mount, Fig. 107. But be careful — both

the air piston and the compression spring

inside the cylinder will be loose. A fter you

clean the parts, wipe the inside of the air

cylinder w ith a thin coat of shutter oil.

In an earlier Craftsman article, we

described the technique for measuring

the memory time lag using an oscillo

scope. The technique involves connect

ing the vertical input of the scope be

tween the release switch and the memory

switch. Also short across the memory

capacitor. When you then release the

shutter at the X setting, you can measure

the length of time that the trace stays at

OV — that's the memory time lag.

But you don 't have to rush out and buy

an oscilloscope to repair the XD-11. For

one thing, adjusting the memory time lag

isn't a common repair. And, if necessary,

you can adjust the memory time lag by

making repeated auto-exposure tests.

Remember, an inaccurate memory time

lag causes erratic and incorrect expo

sures. So, by turning the setscrew, you

can change the memory time lag until the

auto exposures are consistent and cor

rect. If you do turn the setscrew, Fig. 107,

lock the adjusted position w ith cement.

The more common mechanical repairs

involve the levers at the bottom of the

mirror cage, Fig. 108. For example, you

may find that the camera works properly

w ith the lens removed. However, as soon

as you install the lens, the camera jams.

W hat happens is that the diaphragm fails

to reopen after the exposure — usually

because the mirror-tensioning lever, Fig.

108, isn't moving freely.

In Fig. 108, we've removed the two com

bination magnets at the bottom of the mir

ror cage. Remember, though, that remov

ing the combination magnets requires that

you readjust their positions on reassembly.

You can now see the diaphragm-control

parts.

The mirror-tensioning lever moves to

the charged position, Fig. 109, when you

cock the shutter. Notice in Fig. 109 that

the tensioning-lever latch now engages

the mirror-tensioning lever. Then, when

the mirror-release magnet disengages the

m irror-release lever,

Fig.

106,

the

d ia p h ra g m -c lo s in g

lin k

p u lls

th e

diaphragm-closing lever from right to left.

Fig. 110.

Also, the diaphragm-closing link ro

tates the gear segment, Fig. 110, in a

counterclockwise direction. The gear seg

ment then turns the ratchet gear (remain

ing w ith the diaphragm-control magnet).

Stopping the ratchet gear arrests the

movement of the gear segment. In turn,

the gear segment stops the travel of the

diaphragm-closing link.

A fte r the exposure,

the shutter

mechanism pushes down the mirror-

return link, Fig. 106. The mirror-return

link now disengages the tensioning-lever

latch from the mirror-tensioning lever,

Fig. 108. As the mirror-tensioning lever

moves clockwise, it drives the diaphragm-

closing link back to its original position.

So, if the diaphragm w o n 't reopen after

the exposure,

suspect the mirror-

tensioning lever. Dirt may be preventing

free travel. As a result, the mirror-

tensioning lever can't push the diaphragm-

closing link against the spring tension of

the lens.

For major repairs, you may have to

separate the mirror cage from the front

plate. Take out the tw o upper mirror-cage

screws, Fig. 111, and the large screw at

the bottom of the mirror cage. Then sepa

rate the mirror cage from the front plate.

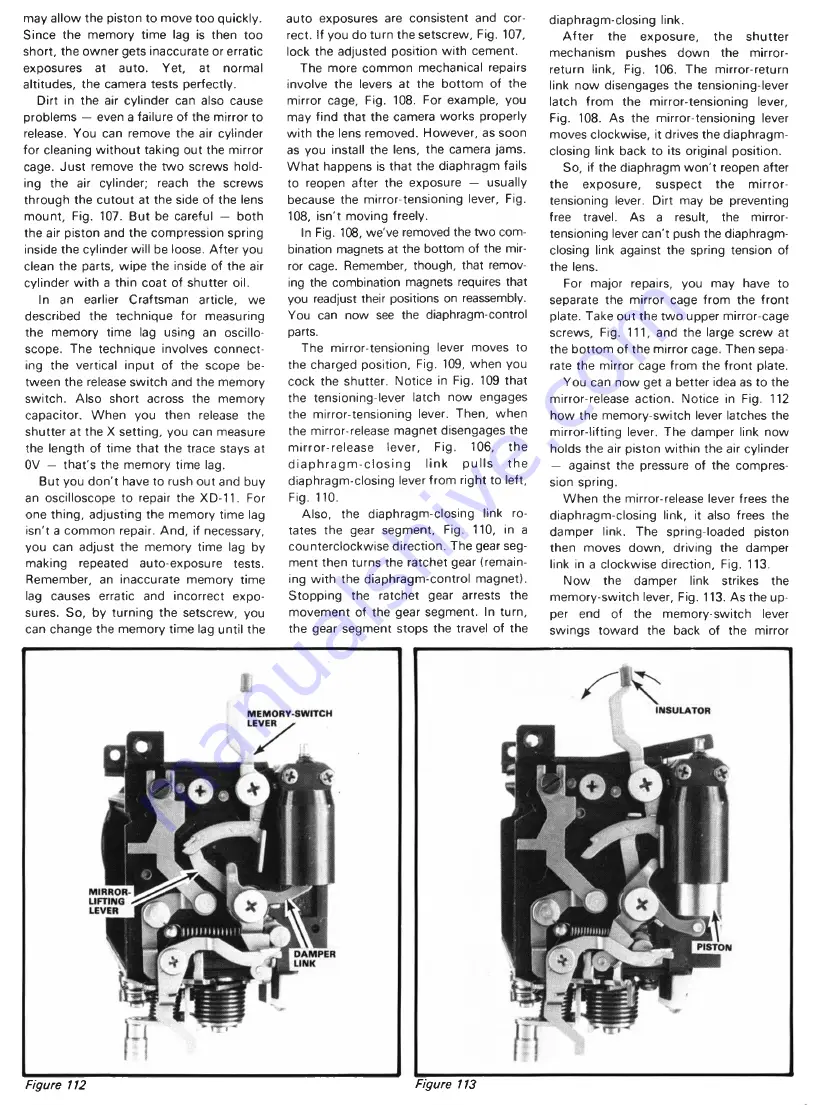

You can now get a better idea as to the

mirror-release action. Notice in Fig. 112

how the memory-switch lever latches the

mirror-lifting lever. The damper link now

holds the air piston w ithin the air cylinder

— against the pressure of the compres

sion spring.

When the mirror-release lever frees the

diaphragm-closing link, it also frees the

damper link. The spring-loaded piston

then moves down, driving the damper

link in a clockwise direction, Fig. 113.

Now the damper link strikes the

memory-switch lever, Fig. 113. As the up

per end of the memory-switch lever

swings toward the back of the mirror

Figure 112

Figure 113