3-40

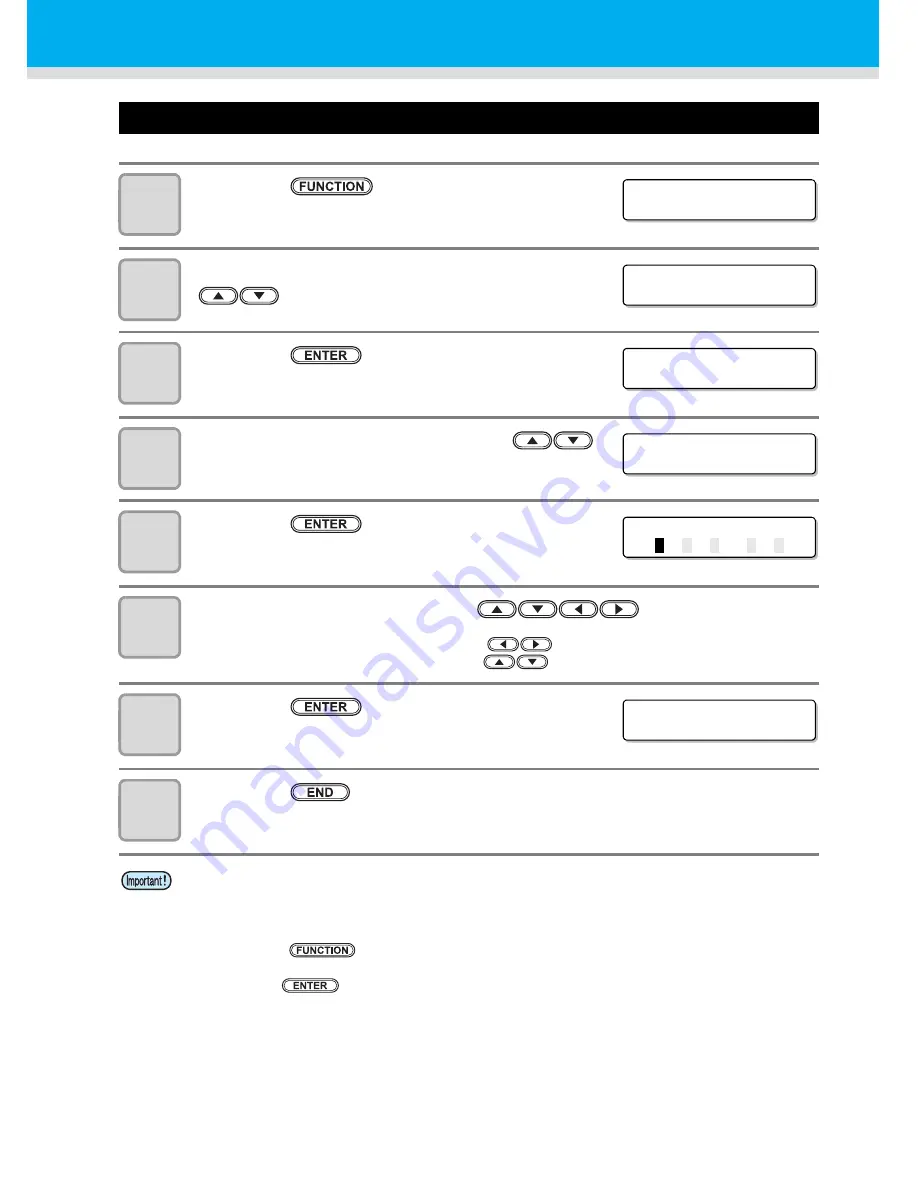

Setting time

1

Press the

key in the local mode.

2

Select [MACHINE SETUP 2] by pressing the

keys.

3

Press the

key.

4

Select [TIME SET] by pressing the

keys.

5

Press the

key twice.

6

Input time by the pressing the

keys.

Year/Month/Day/Time selecting

: by the

keys.

Year/Month/Day/Time inputting

:by the

keys.

7

Press the

key.

• The input time is indicated.

8

Press the

key several times to end.

• The setting of past time is settable only for time up to 8 hours earlier than the presently

indicated time.

• If future time is set by mistake, the previously set time can be set back by the following

operations in step 7.

(1)

Press the

key in step 7. (The input time and the previously set time are

indicated.)

(2)

Press the

key.

Only one change of previous setting can be set back. The time before changed is proceeding

by the elapsed time.

FUNCT I ON

SE TUP

< ENT >

F UNC T I ON

MACH I NE S E T UP 2 < EN T >

MACH I NE S E T UP 2

CONF I RM . F EED

< e n t >

MACH I NE S E T UP 2

T I ME SE T

< e n t >

T I ME SE T

2 0 1

2

. 1 0 . 0 5

1 5 : 3 0 : 0 0

T I ME SE T

2 0 1 2 . 1 0 . 0 5

1 5 : 3 0 : 0 0

Содержание TS3-1600

Страница 1: ...MIMAKI ENGINEERING CO LTD URL http www mimaki co jp D201937 15...

Страница 7: ...vi...

Страница 99: ...3 35 Machine settings 3 Convenient use Examples of Output...

Страница 101: ...3 37 Machine settings 3 Convenient use 7 Press the key 8 Press the key several times to end...

Страница 118: ...3 54...

Страница 151: ...Setting Routine operations 4 33 4 Routine Maintenance 8 Press the key several times to end...

Страница 164: ...4 46...

Страница 183: ...Warning labels 6 7 6 Appendix No Reorder Label 1 M901549 2 M903239 3 M903330 4 M903405 5 M904810...

Страница 189: ...6 13 Function Flowchart 6 Appendix To P 6 14 To P 6 20 To P 6 26 To P 6 27 To P 6 28...

Страница 193: ...6 17 Function Flowchart 6 Appendix OFF LEVEL 1 3 1 Wh i t e L a y P r t SE L OF F...

Страница 205: ...D201937 15 17022012...

Страница 206: ...NH FW 5 3 Printed in Japan MIMAKI ENGINEERING CO LTD 2012...