2-2

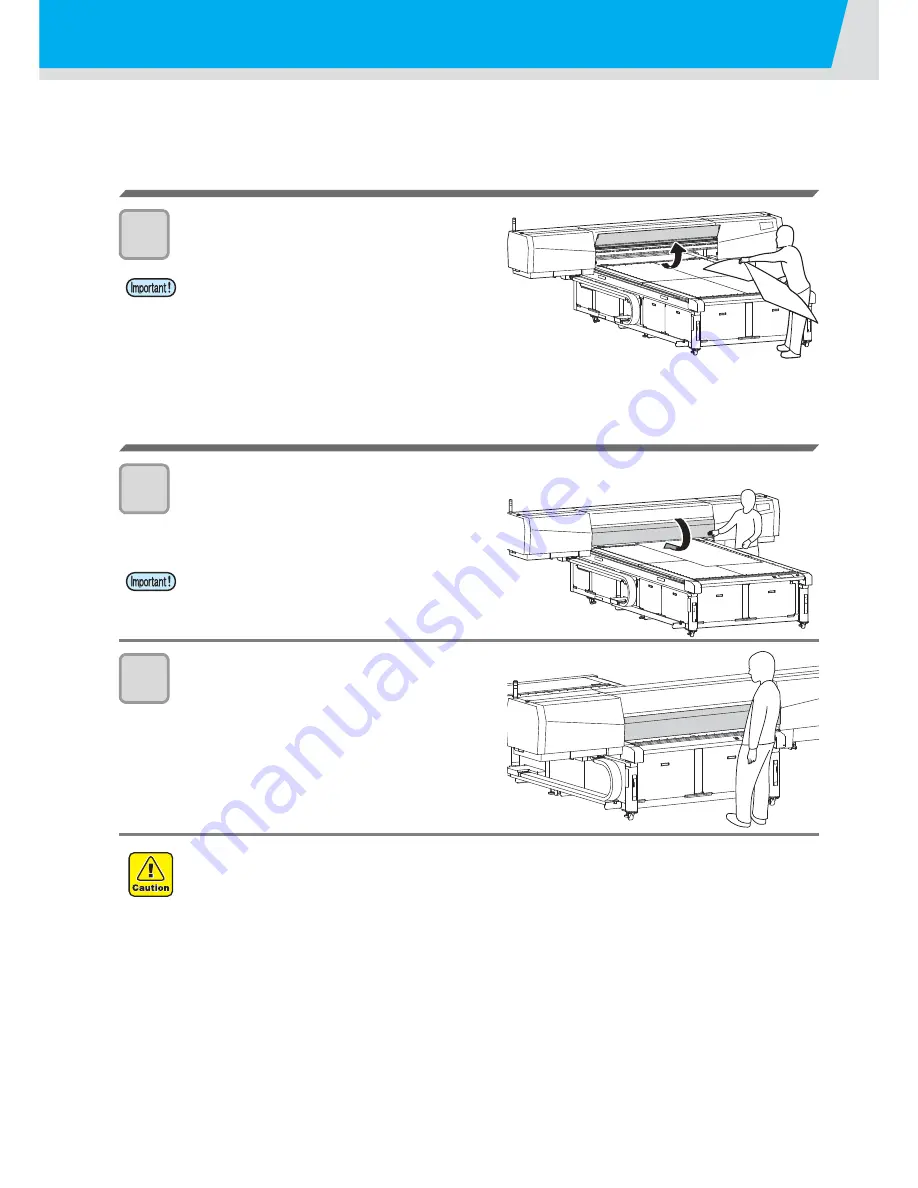

How to use the opening/closing door

Close the door while performing the drawing to avoid the bad effect to be caused by UV LED.

When setting the media

1

Set the media after opening the door.

When drawing the image

1

Close the door.

2

Perform drawing while keeping the door

closed.

• When setting the media, avoid contact of the media to the

door. The door could be closed by vibration.

• Close the door slowly so that the door may not be

damaged.

• Do not open the door while drawing. The UV light could damage your eyes or skin.

• Inserting your hand while drawing under the door could cause injury due to touching with the carriage.

Содержание JFX-1631/1615 Plus

Страница 1: ...MIMAKI ENGINEERING CO LTD URL http eng mimaki co jp D202017 20...

Страница 82: ...3 38...

Страница 122: ...4 40...

Страница 134: ...5 12...

Страница 138: ...6 4...

Страница 152: ...6 18...

Страница 153: ...D202017 20 25122014...

Страница 154: ...SN FW 2 80 MIMAKI ENGINEERING CO LTD 2014...