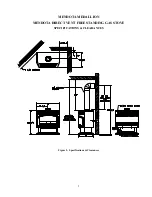

A-2. ELEVATED RISE THROUGH-THE-WALL VENTING

The maximum vertical rise is 15 ft. when used with a maximum horizontal run of 15 ft. For other venting

configurations within these maximum limits (see Figure 5, page 10).

NOTE: The horizontal run of vent pipe must be level or have a ¼" rise for every 1' of run toward the

termination. Never allow the vent to run downward. This will cause high temperatures and the

possibility of a fire.

USING OFFSETS AND RETURNS: A single 90

º

vertical-to-horizontal elbow is already calculated into

the allowable maximum 12' horizontal run. Each additional 90

º

elbow reduces the maximum horizontal

distance by 3'. Example: by using three total 90

º

elbows the maximum horizontal distance has been

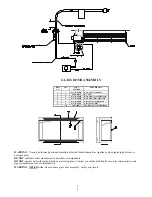

reduced to 6 ft. (3 - 1 = 2 elbows x 3' = 6'; 12’ Max. - 6' of elbows = 6' of horizontal run). Note: 45

º

elbows reduce the maximum horizontal distance by 1½ '.

Always maintain the proper rise (6' for each

elbow used after the initial elbow) for the calculated total run when using elbows.

SUPPORT: Horizontal runs of pipe will require one vent support for every 3 ft. of pipe.

CAUTION: If a vertical-to-horizontal elbow is enclosed within a wall, floor or ceiling, a top air space

clearance of 3" must be maintained.

Be sure to maintain 1 1/2" air space clearances to any combustibles.

IMPORTANT: REFER TO DRAWINGS ON PAGES 9 & 10 WHILE FOLLOWING THESE INSTRUCTIONS.

The Medallion Stove must be installed by a qualified Mendota service person.

1. Position stove in desired location. See page 7 for guidelines on proper vent cap placement on exterior

of home. Check to determine if wall studs are in the way when vent system is attached. If this is the

case you may want to adjust the stove location.

2. Locate position where vent pipe will pass through any ceilings and will penetrate the outside wall.

Since vent pipe sections "overlap" we suggest preassembling and measuring the total vent pipe run so

you can more accurately locate the point where the vent pipe will penetrate the outside wall. Be sure

components are properly twist locked and leak proof. (See Pg. 8 "

TWIST LOCK PROCEDURE

"). Be

sure all vent components are properly twist lock-proof. Be sure Millpak 2000° sealant (#65-06-00909)

is used in the inner joints of all adjustable pipe sections.

3. Cut and frame a 10" x 10" opening in the outside wall and in any ceiling openings. The outside wall

hole must be positioned so the vent system will run level or have a ¼ " on rise AND be perpendicular to

the wall. The height of the opening must be located to meet all local and national building codes and

not allow the termination to be easily blocked or obstructed. A ceiling firestop spacer is required at any

floor (ceiling) opening.

*NOTE: DO NOT SEPARATE TELESCOPING SECTIONS USE AS COMPLETE ASSEMBLIES.

4. Connect vent pipe to the stove adapter on top of stove vent outlet.

5. The horizontal pipe must end flush with the exterior wall of the home. Horizontal pipe will require a

proper support every 3 ft. of vent pipe. THERE MUST BE A MINIMUM OF 1 1/2" CLEARANCE

TO COMBUSTIBLES FROM ALL VENT PIECES. Use decorative wall thimble kit on inside of wall

before connecting horizontal run to vent termination.

6. From the exterior of the home, slide the horizontal vent cap over the end of the horizontal pipe and

tightly secure the vent cap to the wall with screws. Seal with high quality caulking.

NOTE: Do not recess vent termination cap into the wall or siding.

1

2

Содержание MEDALLION

Страница 21: ...Log Fire View Figure 9 Log Module 2 0...

Страница 32: ...TAPE SHUT POSTAGE NEEDED JOHNSON GAS APPLIANCE COMPANY 520 E AVENUE N W CEDAR RAPIDS IA 52405 3 1...

Страница 33: ...NOTES NOTES 3 2...

Страница 34: ...MENDOTA EXTENDED LIFETIME PROTECTION AND LIMITED WARRANTY MENDOTA MEDALLION SDV40 DIRECT VENT GAS STOVE 3 3...