USE AND MAINTENANCE

ENGLISH

Cod. F07022163

pag.13

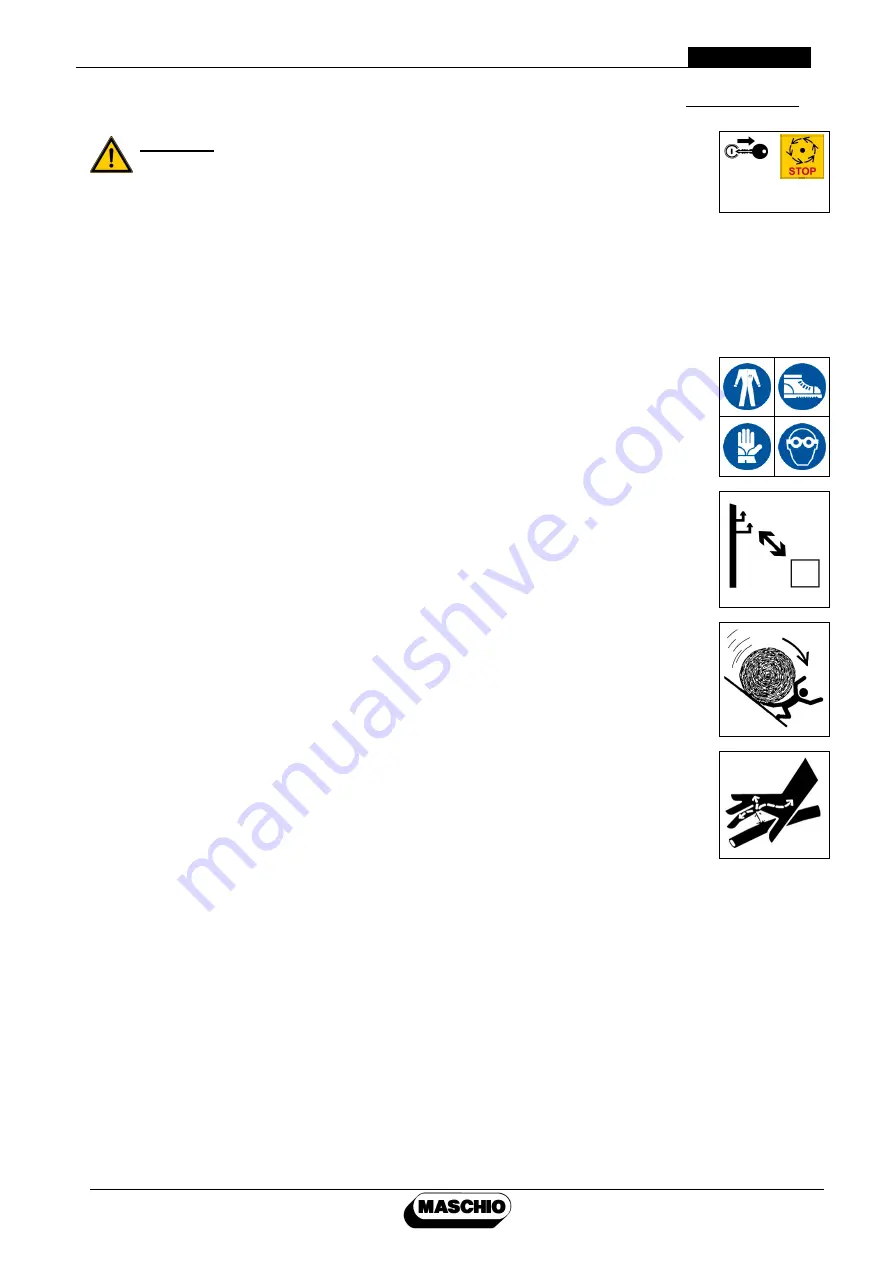

The area in front of the pick-up is very dangerous; when the machine is in operation,

never introduce

the

forage using the hands, feet or the help of any other object.

WARNING! In the event of product accumulation in the feed zone:

Stop the tractor, remove the keys from the dashboard and wait for all the

moving parts of the machine to stop completely.

Switch off the “FF Control” system.

Follow the instructions shown in the paragraph

“8.4_ Unblockage of the product”

.

Do not use the controls, tubes and other protruding parts of the machine to hang things on.

Assemble, operate and detach the cardan shaft always respecting the information and safety rules for use

of the cardan shaft contained in the booklet provided by the manufacturer of the cardan shaft and

delivered together with it.

It is absolutely forbidden to transport persons or animals on the machine or tractor.

During maintenance and/or repair work it is obligatory to wear protective clothing, cut

resistant gloves, safety footwear and goggles.

Do not wear clothes that could get caught on the moving parts. If there is a risk of

objects being thrown out, wear a protective helmet fitted with a visor.

For further information consult the paragraph

“4.6_Clothing”

.

Take great care to maintain a minimum safety distance when operating in the vicinity of

electrical power lines; the machine is made mainly of metal and therefore if it comes into

contact with an electrical line or if there is a discharge between the line and the machine

the operator could be electrocuted with possible fatal consequences.

If it is necessary to operate in the vicinity of electrical power lines contact the competent

electricity company.

Unload the bales on flat ground or in a suitable position if the ground is sloping.

High pressure hydraulic oil can penetrate the skin and cause serious injury. Before

detaching any tubes or doing any checks the system should always be depressurised.

If any hydraulic oil under pressure should penetrate the skin go immediately to hospital

otherwise there is a serious risk of infection.

MASCHIO FIENAGIONE declines all liability resulting from failure to observe these safety warnings.

Содержание ENTRY 120

Страница 2: ......

Страница 78: ...ENGLISH USE AND MAINTENANCE pag 76 Cod F07022163 11 8_HYDRAULIC DIAGRAM U2 U1 D2 D1...

Страница 86: ...ENGLISH USE AND MAINTENANCE pag 84 Cod F07022163...

Страница 87: ......