41

SC100/200 Series Function Block Application Manual EM-6460-C

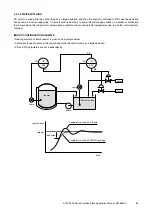

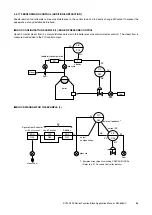

4.3.10 VARIABLE PID CONTROL

Different sets of PID parameters are automatically applied following loop characteristics changes caused by switching sen-

sor’s measuring range

,

control valves or set values (e.g. set values change in accordance with the progress of program steps

■

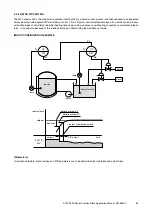

LOOP CONFIGURATION EXAMPLE: TEMPERATURE CONTROL DIVIDED INTO THREE TEMPERATURE ZONES

■

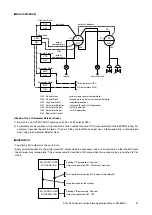

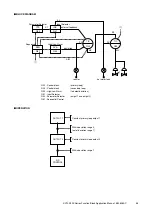

BLOCK DIAGRAM

■

OPERATION

The TIC’s current SP is supplied to the input of G30 High/Low Alarm block. High and low setpoints divide the set value range

in three zones. A Parameter Setter block is applied to each zone.

The high/low setpoints should be provided with a deadband to avoid cycling between parameters.

[Caution of using Parameter Setter block]

Parameters in each function block can be rewritten approx. one hundred thousand (100,000) times (according to nominal

specification of the EEPROM).

For example, if you rewrite a parameter every one hour, the EEPROM is usable approx. eleven years. Please consider this

information carefully when you design an application of this function block.

fuel

TIC

PV

MV

furnace

Setting different PID parameters for

each of three temperature zones

temp

temp

PV

current SP

parameter setting

TIC

G02

MV

PMS

G31

PMS

G32

PMS

G33

PVA

G30

SEQ

Parameter Setter

High/Low Alarm Sequence

G81

Parameters are switched by one-shot command.

setpoint

PID parameters

low limit

A2

high limit

A1

G31

G32

G33