ⱥㄒ㸭(1*/,6+

12

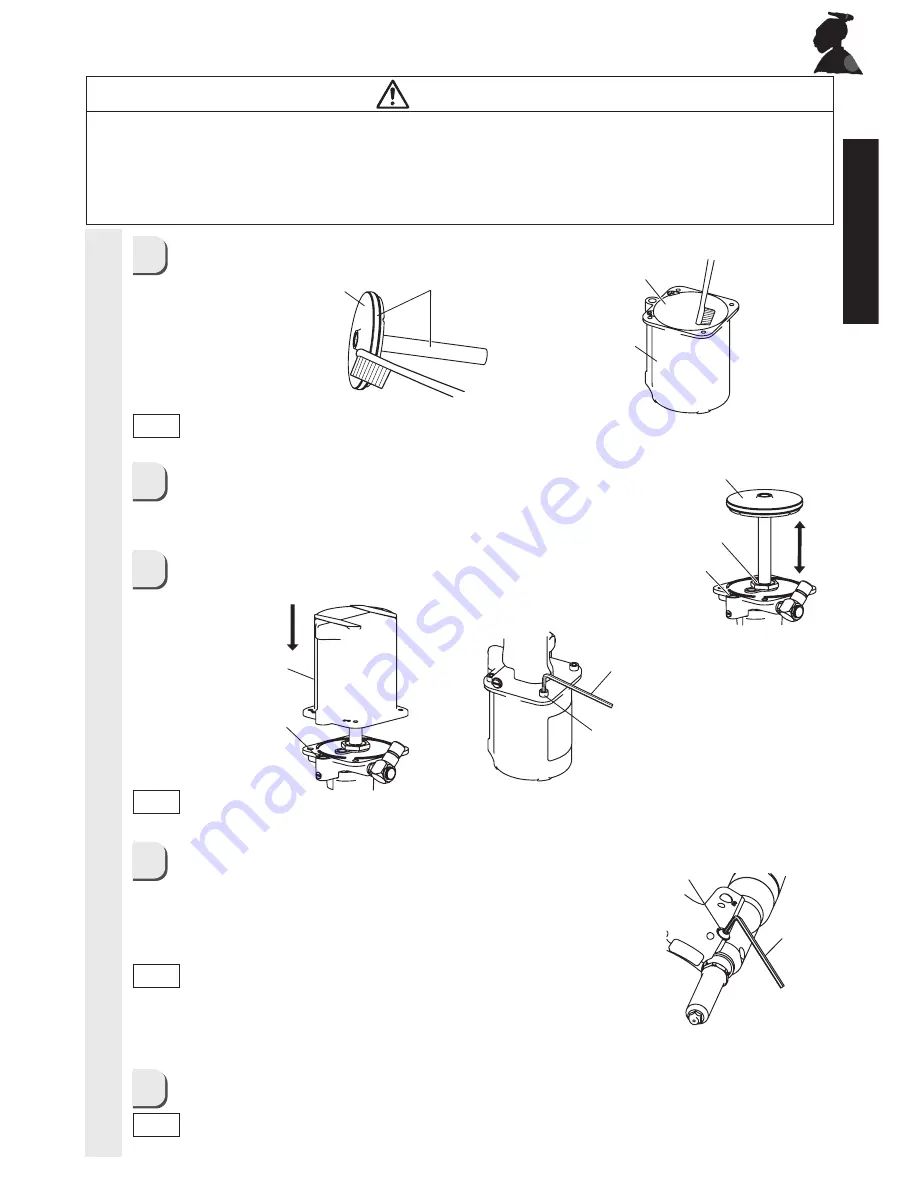

RE-ASSEMBL

Y

9

Push and insert the Air Piston Unit into the oil supply

port and manually perform a piston motion for several

times. Wipe off hydraulic oil spilling out of the oil

supply port.

Attach the Cylinder Cup on the Air Piston Unit, and

keeping pressing it down tighten the 4 hex socket

screws.

After assembled Frame Head with Frame A, turn the unit

as the Bleed Plug (hex socket bolt) comes to the upper side.

Then, loosen it using a hex key wrench (AF 4mm) in order to

let excessive hydraulic oil and air (bubble) out.

After making sure that hydraulic oil no longer comes out,

tighten the Bleed Plug again.

Wipe off hydraulic oil adhering to the main body or spilling out before use.

10

11

12

Air Piston Unit

Oil supply port

Cylinder Cup

Bleed Plug

Hex key

wrench

(AF 4mm)

O-ring SS9.5

Hex socket screw

(x4)

O-ring

Hex key wrench

(AF 4mm)

8

Apply grease to the O-Ring and rod of Air Piston Unit and to the inside of Cylinder

Cup using brush.

Cylinder Cup

Apply grease

Apply grease

Air Piston Unit

ە

Avoid skin contact with substances such as hydraulic oil, lubricating oil and grease.

Such substances may cause inflammation of the skin. If they come into contact with your skin,

wash the affected area thoroughly.

ە

Maintain the tool with due care.

Refer to the Instruction Manual for details on replacing parts and attachments, otherwise injury may

occur.

CAUTION

ە

Before assembling, be sure to apply lubricant such as grease to each sliding section.

ە

Recommended grease is Grease

JUDGH

1~2.

Note

ە

Assemble in reverse order of disassembly.

ە

Make sure the O-ring SS9.5 is surely set in the counterbore.

Note

ە

Note that hydraulic oil may squirt out when you loosen the

ࠉ

Bleed Plug.

ە

The work should be done by necessity after feeding hydraulic

oil. Otherwise there may be detrimental to the tool in loading

rivet or breakage of Frame.

Note

ە

During disassembly/assembly, be careful to prevent cutting dusts of metal and

other objects from getting into the hydraulic oil and Air Cylinder.

Note