Section 5: Torch Consumables and Cutting Charts

Spirit II User’s Manual

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

5-18

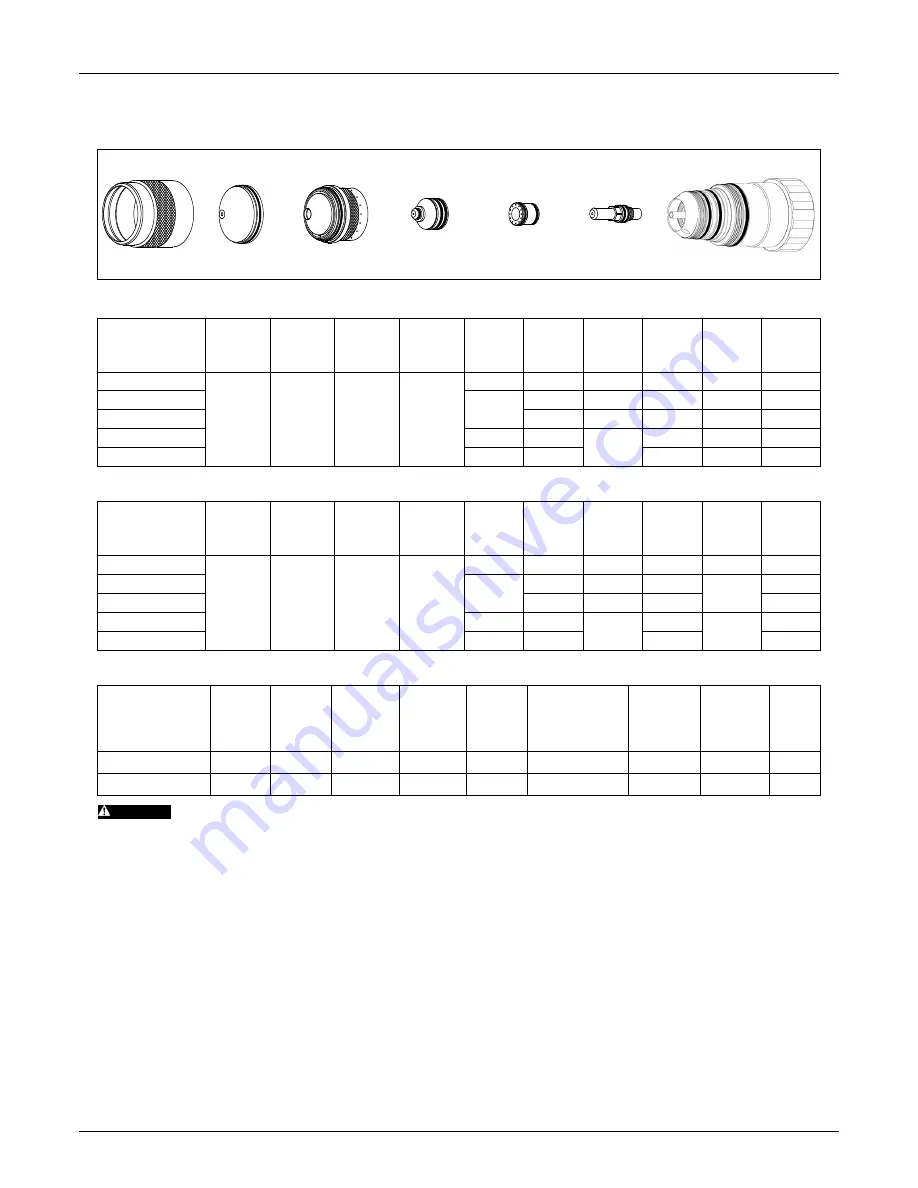

Mild Steel - 100 Amps - Copper Electrode

Oxygen Plasma / Air Shield / Air Preflow & Postflow

Shield Cap

Nozzle

Electrode

BK277286

BK277284

BK277282

Outer Cap

Retaining Cap

Swirl Ring

Torch Head

BK284150

BK277151

BK277283

BK279100

Imperial*

Material

Thickness

Preflow

Plasma

Shield

Postflow

Arc

Voltage

Travel

Speed

Cutting

Height

Pierce

Height

Pierce

Time

Kerf

Width

(in)

(psi)

(psi)

(psi)

(psi)

(volts)

(ipm)

(in)

(in)

(msec)

(in)

1/4

25

83

26

81

125

150

.090

.200

300

0.070

3/8

130

100

.130

.250

400

0.078

1/2

65

.155

.300

500

0.085

5/8

143

47

.185

.325

800

0.092

3/4

145

35

.350

1000

0.098

Metric*

Material

Thickness

Preflow

Plasma

Shield

Postflow

Arc

Voltage

Travel

Speed

Cutting

Height

Pierce

Height

Pierce

Time

Kerf

Width

(mm)

(psi)

(psi)

(psi)

(psi)

(volts)

(mm/m)

(mm)

(mm)

(msec)

(mm)

6

25

83

26

81

124

3950

2.1

4.9

300

1.8

10

130

2405

3.3

6.5

500

2.0

12

1850

3.7

7.3

2.1

16

143

1180

4.7

8.3

1000

2.3

20

145

800

9.0

2.5

Marking* – For All Material Thicknesses

Type of Gas

Preflow

Plasma

Shield

Postflow

Arc

Voltage

Travel

Speed

Marking

Height

Initial

Height

Pierce

Time

(Plasma) (Shield)

(psi)

(psi)

(psi)

(psi)

(volts)

(ipm) (mm/min) (in) (mm) (in) (mm) (msec)

Nitrogen Nitrogen

N/A

25

25

N/A

130

250

6350

.100 2.5 .100 2.5

0

Argon

Air

N/A

50

25

N/A

60

100

2540

.100 2.5 .100 2.5

0

WARNING

Do not connect H17 (combustible gas) to the gas inputs (Pre/Postflow, Plasma, or Shield) at the same time as

Oxygen or Air.

* Use an arc transfer height (ignition height) of .200” (5.1 mm) for cutting and .100” (2.5 mm) for marking.

(Revised 08/03/2017)