- - 7

ASSEMBLY INSTRUCTION:

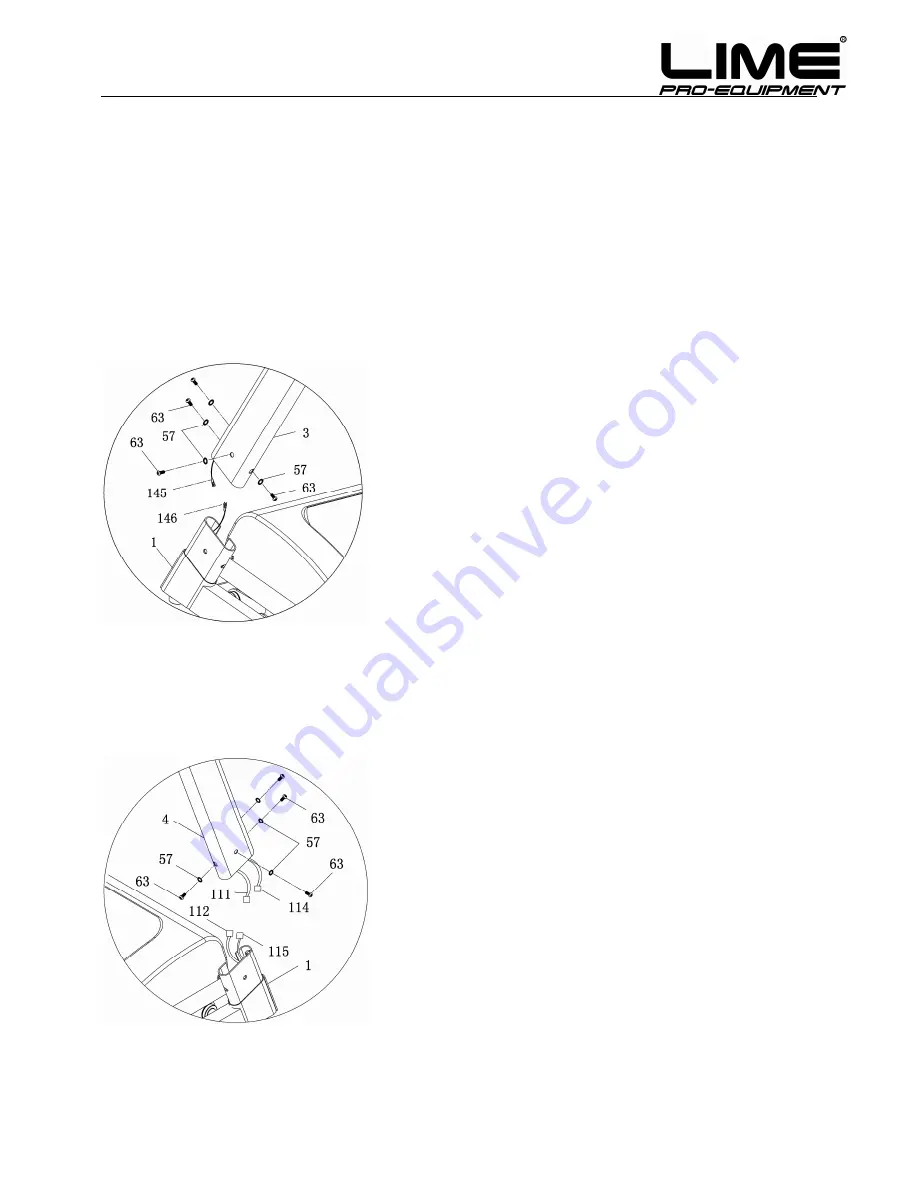

STEP 1:

STEP 2:

STEP 3:

1. Open the carton; take out the spare parts,

and put the MAIN FRAME (#1) on the ground.

4.

Connect the signal line (#111, #114) at the

end of the RIGHT UPRIGHT TUBE (#4) and

the signal line (#112, #115) at the bottom of the

MAIN FRAME (#1); then insert the RIGHT

UPRIGHT TUBE (#4) into the unit.

Notice: Don’t do assembly with strong

force, you may break the insulating layer of

the signal line, or the plug pins may be

curved, which would result in bad signal

connections.

5.

Put the BOLT (#63) and the WASHER (#57)

together, then lock the RIGHT UPRIGHT TUBE

(#4) onto the MAIN

FRAME (#1) with #6

ALLEN WRENCH.

2.

Connect the signal line (#145) at the end of the

LEFT UPRIGHT TUBE (#3) and the signal line

(#146) at the bottom of the MAIN FRAME (#1),

then insert the LEFT UPRIGHT TUBE (#3) into the

unit.

Notice: Don’t do assembly with strong force,

you may break the insulating layer of the

signal line, or the plug pins may be curved,

which would result in bad signal connections.

3.

Put the BOLT (#63) and the WASHER (#57)

together,then lock the LEFT UPRIGHT TUBE (#3)

onto the MAIN FRAME (#1) with #6 ALLEN

WRENCH.

Содержание D 11.0 Performance

Страница 1: ... 1 OWNER S MANUAL ...

Страница 26: ... 26 EXPLODED DRAWING ...