Mechanical installation

Mounting of g500 short/servo adapters with clamping connection

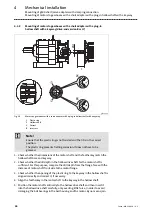

Mounting the shrink disc with a rotating cover

42

Lenze ¯ MA 12.0018 ¯ 4.1

1.

5.

1

1

2

2

Fig. 13

Shrink disc cover

1

Protection cover

2

Clamping screws

1. Remove protective cap (1), if available.

2. Check machine shaft:

–

Diameter in fit tolerance h6

–

Material yield point Re > = 360 MPa

–

E−module approx. 210000 MPa

–

Surface roughness R

z

£

15

m

m

–

Concentricity in order to prevent unnecessary additional forces caused by

tensioning.

3. Thoroughly clean and

degrease

hollow shaft bore and machine shaft.

Note!

Thoroughly degrease the bore over the

entire

hollow shaft length to

make sure that remainders of the anticorrosion agent will not be carried

off into the area of the shrink disc when pushing on the machine shaft.

4. Slightly loosen clamping screws (2) one after the other, do

not

unscrew!

5. Push drive onto machine shaft.

6. Slightly tighten clamping screws manually.

7. Tighten clamping screws (2) one after the other (see Fig. 14) in several passes,

with rising torque, evenly until the indicated screw−tightening torque (see Tab. 6 )

is reached at all screws.

GT−GNG−003.iso/dms

Fig. 14

Explanation: "one after the other"