Mechanical installation

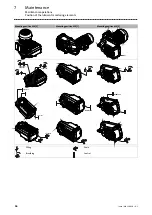

Mounting of g500 short/servo adapters with clamping connection

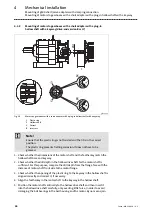

Mounting the shrink disc with a rotating cover

43

Lenze ¯ MA 12.0018 ¯ 4.1

Tip!

Several (in general more than 5 ) passes are necessary until the full

tightening torque is reached at all screws!

The shrink disc is mounted correctly and fixed when the faces of the outer ring and the

inner ring are aligned (Fig. 15). Minimum misalignments are permissible.

GT−GNG−001.iso

Fig. 15

Hollow shaft with shrink disk

3

Outer ring

free of grease

4

Inner ring

Hollow shaft bore [mm]

20

25

30

35

40

Clamping screw thread

M6

M5

M6

M6

M8

M6

M8

M6

M8

Width across flats

SW

1)

[mm]

10

8

10

10

13

10

13

10

13

Torque [ Nm ]

12

6

14

14

30

14

30

14

34

Hollow shaft bore [mm]

50

65

75

80

95

105

125

Clamping screw thread

M8

M10

M10

M10

M12

M14

M14

Width across flats

SW

1)

[mm]

13

17

17

17

19

22

22

Torque [ Nm ]

34

70

70

70

121

193

193

Tab. 6

Tightening torque for the clamping screws

1)

Width across flats of the shrink disc clamping screws

Note!

If a different tightening torque is indicated on the shrink disc, this

tightening torque has priority over the value indicated in the table.

8. Push protective cap (1, Fig. 13) onto the shrink disc.

Tip!

For finding out the cause of non−reached torques of the shrink disc

connection, please go through the troubleshooting list in chapter 8.