FIGURE 24

STATIC PRESSURE

TEST

MANOMETER

G25MV UNIT

Page 19

V–TYPICAL OPERATING CHARACTERISTICS

A–Blower Operation and Adjustment

NOTE– The following is a generalized procedure

and does not apply to all thermostat controls.

1– Blower operation is dependent on thermostat

control system.

2– Generally, blower operation is set at thermostat

subbase fan switch. With fan switch in ON position,

blower operates continuously on heating speed.

With fan switch in AUTO position, blower cycles

with demand or runs continuously while heating or

cooling circuit cycles.

3– In all cases, blower and entire unit will be off when

the system switch is in OFF position.

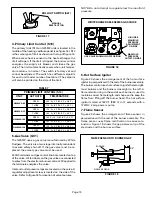

B–Temperature Rise

Temperature rise for G25MV units depends on unit input,

blower speed, blower horsepower and static pressure as

marked on the unit rating plate. The blower speed must

be set for unit operation within the range of “AIR TEMP.

RISE

°

F” listed on the unit rating plate.

To Measure Temperature Rise:

1– Place plenum thermometers in the supply and return

air plenums. Locate supply air thermometer in the

first horizontal run of the plenum where it will not pick

up radiant heat from the heat exchanger.

2– Set thermostat to highest setting.

3– After plenum thermometers have reached their

highest and steadiest readings, subtract the two

readings. The difference should be in the range

listed on the unit rating plate. If the temperature is

too low, decrease blower speed. If temperature is

too high, first check the firing rate. Provided the firing

rate is acceptable, increase blower speed to reduce

temperature. To change blower speed taps see the

Blower Speed Taps section in this manual.

C–External Static Pressure

1– Measure tap locations as shown in figure 24.

2– Punch a 1/4” diameter hole

in supply and return air

plenums. Insert manome-

ter hose flush with inside

edge of hole or insulation.

Seal around the hose with

permagum. Connect the

zero end of the manometer

to the discharge (supply) side of the system. On

ducted systems, connect the other end of manometer

to the return duct as above. For systems with

non–ducted returns, leave the other end of the

manometer open to the atmosphere.

3– With only the blower motor running and the

evaporator coil dry, observe the manometer

reading. Adjust blower motor speed to deliver

the air desired according to the job requirements.

4– External static pressure drop must not be more

than 0.8” W.C. (198.9 Pa).

5– Seal around the hole when the check is complete.

VI–MAINTENANCE

At the beginning of each heating season, the system

should be checked as follows:

A–Filters

Return air filter is supplied with unit. A filter must be

used in order to ensure long life and proper operation.

The filter is located in the return air duct or return air

register. Filters must be cleaned or replaced when

dirty to assure proper unit operation.

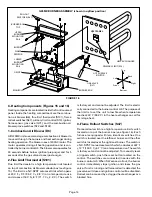

B–Cleaning Heat Exchanger and Burners

NOTE–Use papers or protective covering in front of

furnace while cleaning furnace.

To clean heat exchanger and burners:

1– Turn off both electrical and gas power supplies to

furnace. Refer to figure 1 during disassembly and

reassembly procedures.

2– Disconnect wires leading to burner and heat ex-

changer assembly.

3– Remove front louvered panel and and blower access

panels.

4– Remove flue pipe and draft hood.

5– Disconnect gas piping and move piping out of way

so heat exchanger can slide out front of cabinet.

6– Gas manifold, gas valve, burners and combustion

air blower do not need to be removed and can be

left in place.

7– Locate four screws which hold heat exchanger in

place (two on each side of cabinet). See figure 25.

Remove screws.

8– Slide heat exchanger out of cabinet.

To clean burners:

9– Remove screws holding upper burner mounting rail

(figure 16). Remove rail.

10– Slide burners off each orifice and pull burners from

heat exchanger.

11– Clean holes in burner head (retention ring) with a

wire brush. See figure 20.

12– With a shop vacuum or rags, clean out soot and

scale deposits from burners.

13– Remove screws securing flue box to vestibule

panel. Remove flue box from unit. Leave combustion

air blower attached to flue box.

14– With a shop vacuum or rags, clean out soot and scale

deposits from heat exchanger tubes and flue box.

15– Inspect heat exchanger for corrosion damage, holes

or cracks.