Page 18

Manifold Pressure Check Procedure:

1– Connect a test gauge to outlet pressure tap on gas

valve. Start unit and allow 5 minutes for unit to

reach steady state.

2– While waiting for the unit to stabilize, notice the

flame. Flame should be stable and should not lift

from burner. Natural gas should burn blue.

3– After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to the normal

manifold pressure of 3.5” W.C. (870.2 Pa) for high

fire operation or 1.7” W.C. (422.7 Pa) for low fire.

NOTE–Shut unit off, turn gas valve to “OFF” position

and remove manometer as soon as an accurate

reading has been obtained. Take care to replace

pressure tap plug.

F– Proper Gas Flow

To check for proper gas flow to combustion chamber,

determine Btuh input from unit rating plate or the

specifications tables on page 2. Divide input rating by

Btuh per cubic foot of available gas. Result is the number

of cubic feet per hour required. Determine flow of gas

through gas meter for two minutes. Multiply by 30 to get

hourly flow of gas to burner.

NOTE– To obtain accurate reading, shut off all other

gas appliances connected to meter.

G–High Altitude Derate

A.G.A. certified units must be derated 4 percent for each

1,000 feet (305m) above sea level. Thus, at an altitude of

4000 feet (1210 m), the unit would require a derate of 16

percent.

C.G.A. certified units must be derated 10 percent for

elevations 2000 feet (610 m) to 4500 feet (1370 m)

above sea level.

NOTE–In Canada, use the following high altitude

conversion kits: LB–79766A for G25MV3–60/75; and

LB–79766B for G25MV5–100/120.

NOTE–This is the only permissible field derate for

this appliance.

IMPORTANT

For safety, shut unit off and remove manometer as

soon as an accurate reading has been obtained.

Take care to replace pressure tap plug.

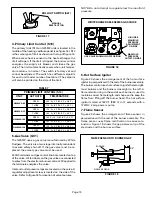

H–Flame Signal

A 20 microamp DC meter is needed to check the flame

signal on the primary ignition control. Use a flame signal

transducer (part number 78H5401) available from Lennox

to measure the flame signal.

Flame (microamp) signal is an electrical current which

passes from the ignition control through the sensor

electrode during unit operation. Current passes from

the sensor through the flame to ground to complete a

safety circuit.

To Measure Flame Signal:

1– Remove front louvered panel and disconnect the

sensor wire from the flame sensor.

2– Place meter in series between flame sensor and

sensor wire. Connect the positive (+) lead of meter

to the sensor wire and the negative (–) lead of the

meter to the flame sensor.

3– Set thermostat for a heating demand and check

flame signal with unit operating. For G25MV series,

a reading of 4 to 6 microamps DC should occur. The

ignition control must see at least 1.5 microamps in

order to keep the gas valve energized.

Flame signal may rise above 5 microamps for the first few

seconds after ignition then level off within the range.

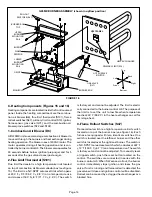

I–Electronically Controlled Blower Motor

To check–out the VSM blower and the VSP2–1 blower

control board, begin with the VSM blower. Refer to figure

23 and follow the check–out procedure as outlined. If the

blower fails any of these tests, do not attempt to repair

the VSM blower. There are no field serviceable parts in

this component. Replace the motor and repeat the check–

out procedure. To verify proper operation of the VSP2–1,

check the board as outlined in the troubleshooting flow-

charts on the last page.

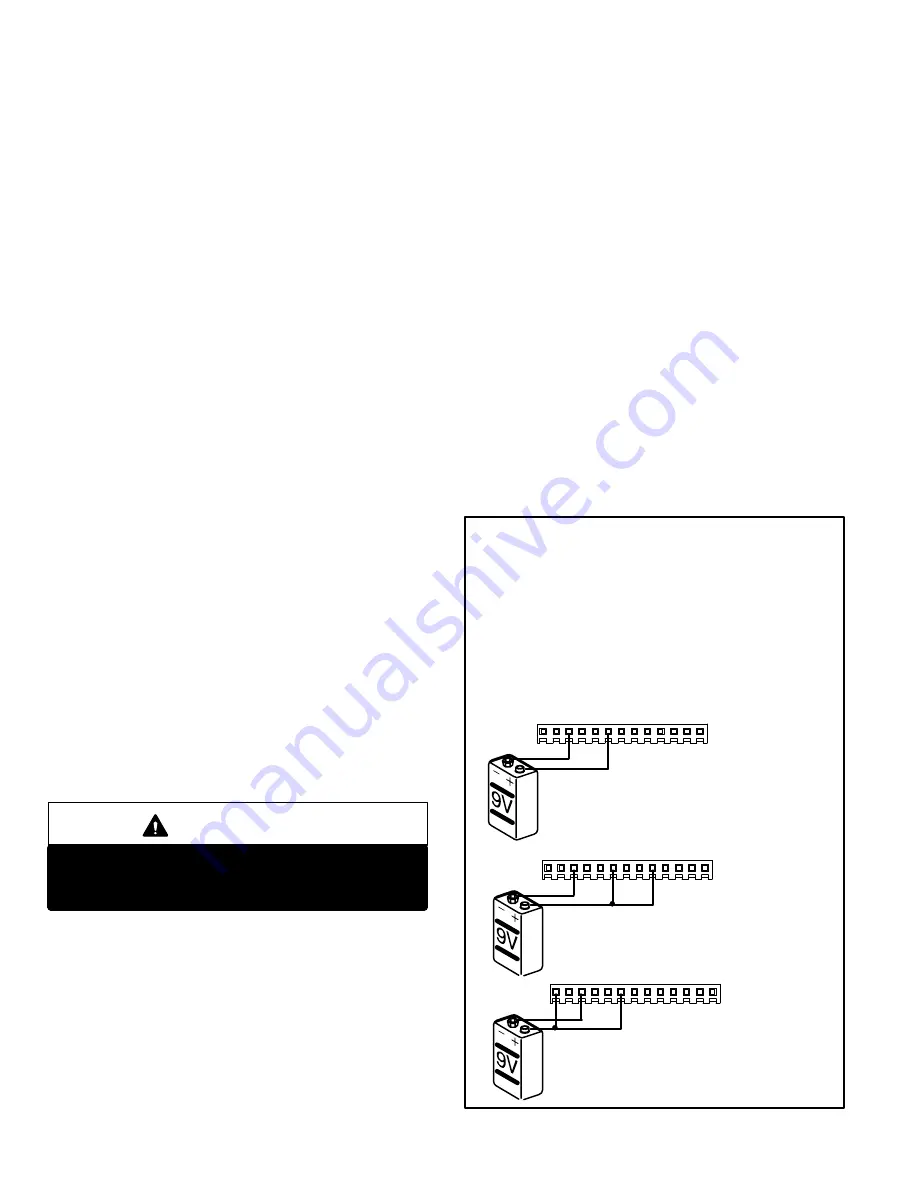

VSM CHECK–OUT

1– Disconnect power to unit.

2– Disconnect 13 pin plug J46 from P46 located on

VSP2–1.

3– Connect voltage source as shown above.

4– Turn on power to unit. Blower should

operate at low speed.

VSM LOW SPEED CHECK–OUT

NOTE–Any A.C. voltage source less than 30 volts or any D.C. voltage

source less than 20 volts may be used to check out the motor. An ordi-

nary 9 volt battery is recommended. Unit transformer T1 secondary

may be used in lieu of a battery. A 9 volt battery will last for about one

day of normal operation. If transformer T1 is used, double check all

wiring connections before placing unit back in operation.

CHECK–OUT PROCEDURE USING J46

5– Disconnect power to unit.

6– Connect voltage source as shown above.

7– Turn on power to unit. Blower should operate at

high speed.

VSM HIGH SPEED

CHECK–OUT

8– Disconnect power to unit.

9– Connect voltage source as shown above.

10–Turn on power to unit. Blower should operate at

heating speed.

VSM HEATING SPEED CHECK–OUT

FIGURE 23

A kit is available from the Lennox parts center to use in testing

the variable speed motor. The kit 70J11 includes a test plug har-

ness to facilitate vsm check–out.

Follow testing procedures

outlined in the instructions provided with the kit. The testing

procedures are different than those listed below.

If not using the kit to test the motor, follow the procedure below.

J46

J46

J46