Page 15

FIGURE 17

ROLLOUT SWITCH (S47)

MANUAL

RESET BUTTON

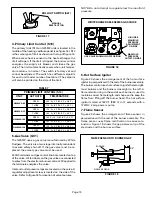

4–Primary Limit Control (S10)

The primary limit (S10) on G25MV units is located in the

middle of the heating vestibule panel (see figure 16). S10

is the same type of limit as shown on the top of figure 14.

When excess heat is sensed in the heat exchanger, the

limit will open. If the limit is tripped, the burner control

energizes the supply air blower and closes the gas

valve. The limit automatically resets when unit temper-

ature returns to normal. The switch is factory set and

cannot be adjusted. The switch has different setpoints

for each unit model number. See table 7. The setpoint

will also be printed on the side of the limit.

TABLE 7

PRIMARY LIMIT CONTROL (S10)

UNIT

ACTUATE

TEMPERATURE

G25MV3–60

OPEN

200

F + 5

F (93.3

C + 2.8

C)

G25MV3–60

CLOSE

170

F + 8

F (76.7

C + 4.4

C)

G25MV3–75

OPEN

175

F + 5

F (79.4

C + 2.8

C)

G25MV3–75

CLOSE

145

F + 8

F (62.8

C + 4.4

C)

G25MV5–100

OPEN

190

F + 10

F (87.8

C + 5.6

C)

G25MV5–100

CLOSE

160

F + 8

F (71.1

C + 4.4

C)

G25MV5–120

OPEN

150

F + 5

F (65.6

C + 2.8

C)

G25MV5–120

CLOSE

120

F + 8

F (48.9

C + 4.4

C)

5–Gas Valve (GV1)

The G25MV uses a gas valve manufactured by White

Rodgers. The valve is a two-stage internally redundant

to assure safety shut–off. If the gas valve must be re-

placed, the same type valve must be used.

24VAC terminals and gas control knob are located on top

of the valve. All terminals on the gas valve are connected

to wires from the electronic burner control. 24V applied to

the terminals energizes the valve.

Inlet and outlet pressure taps are located on the valve. A

regulator adjustment screw is located on the side of the

valve. Refer to figure 18 for location of valve features.

NOTE–Do not attempt to regulate low fire manifold

pressure.

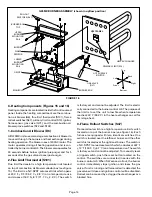

FIGURE 18

WHITE RODGERS 36E SERIES GAS VALVE

GAS VALVE SHOWN IN OFF POSITION

HIGH FIRE

MANIFOLD

PRESSURE

ADJUSTMENT

ON SIDE

MANIFOLD

PRESSURE

OUTLET ON SIDE

6–Hot Surface Ignitor

Figure 20 shows the arrangement of the hot surface

ignitor in perspective with the rest of the burner assembly.

The burner control uses hot surface to ignite the two right-

most burners and the burners cross-light to the left. A

flame retention ring in the end of each burner is used to

maintain correct flame length and shape and to keep the

flame from lifting off the burner head. The hot surface

ignitor is rated at 1800

F (982

C) in 17 seconds with a

120VAC 4 amp power source.

7–Flame Sensor

Figure 20 shows the arrangement of flame sensor in

perspective with the rest of the burner assembly. The

flame sensor uses flame rectification to sense com-

bustion. Figure 19 shows the gap between tip of the

electrode and the burner surface.

FIGURE 19

FLAME SENSOR TO BURNER GAP

BURNER

FLAME SENSOR

3/4”