21

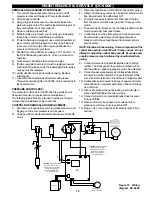

TROUBLESHOOTING

Provided you have followed the instructions, the sprayer will operate efficiently and give trouble-free service.Should

any unexpected problem arise you can, in most cases, remedy the problem by following the chart below. If yo u find

that you cannot correct the problem, then take the sprayer to your nearest authorized service agency. Many of the

“causes” listed are unlikely to happen. However, all are included in an attempt to cover every possibility.

IT IS ABSOLUTELY ESSENTIAL FOR TROUBLE-FREE OPERATION THAT YOUR AIRLESS SPRAYER BE KEPT CLEAN AND FREE OF

RESIDUAL PAINT BUILD-UP ON THE INTERNAL PARTS. IT MUST BE CLEANED AND LUBRICATED AFTER EVERY USE.

Cause

1)

Blown fuse or tripped circuit breaker on supply

or sprayer.

2)

Safety shut-off has been activated.

(DC-4000 only)

3)

Power cord or extension cord not properly

connected.

1)

Pressure control knob set too low.

2)

Clogged spray tip or filters.

3)

Frozen or hardened paint in pump.

4)

Worn motor brushes.

1)

Prime valve closed.

2)

Pump inlet screen clogged.

3)

Suction tube clogged or loose.

4)

Stuck or clogged foot valve or shaft valve.

5)

Clogged spray tip.

6)

Packings dry or worn.

1)

Worn spray tip.

2)

Pressure control knob loose.

3)

Unit not primed.

4)

Fluid leakage.

5)

Spray tip too large.

6)

Worn prime vavle leaking back.

7)

Worn of dirty foot valve, shaft valve, or lower

packings.

8)

Clogged gun filter causes pump not to run after

unit is primed and trigger is pulled.

1)

Upper packings worn.

2)

Worn piston.

1)

Spray tip too large or worn.

2)

Pressure set too low.

3)

Insufficient fluid delivery.

4)

Paint too thick.

5)

Gun filter plugged.

1)

Worn ball or seat on gun.

2)

Foreign matter or paint buildup between ball

and seat on gun.

3)

Ball not in correct position.

1)

Packing or tip is worn.

2)

Gun not shutting off.

1)

Worn valve ball on gun.

1)

Spray tip or gun filter plugged.

1)

Partially plugged spray tip or filter.

Problem

Ia

Sprayer does not start

up.

(DC-4000 control box,

indicator light off)

Ib

Sprayer does not start

up.

(DC-4000 control box,

indicator light on)

II

Sprayer starts up but

does not draw up paint.

III

Sprayer will not

maintain pressure or

has low output.

IV

Upper end of fluid

section leaks.

V

Poor spray pattern.

VI

Spray gun won’t shut

off.

VII

Spray tip leaks.

VIII Spray gun leaks.

IX

Spray gun won’t spray.

X

Low paint output from

spray gun.

Remedy

1)

Check and replace fuse or reset circuit breaker.

(determine cause if possible).

2)

Turn off unit 2-5 seconds. Turn pressure to minimum

and turn on. Indicator light should be on.

3)

Check and repair if necessary.

1)

Turn knob to higher setting.

2)

Follow Pressure Shut Down Procedure. Remove and

clean spray tip and/or filter. Replace.

3)

Remove and clean Fluid Section parts. Re-install.

4)

Replace motor brushes.

1)

Open prime valve. Keep valve open while pressure

control knob is in prime position. Close valve after unit

is primed.

2)

Remove and clean inlet strainer.

3)

Remove and clean suction tube, tighten.

4)

Refer to maintenance section of manual.

5)

Relieve pressure using the Pressure Shut Down

Procedure. Remove spray tip and replace.

6)

Repack Fluid Section.

1)

Follow Pressure Shut Down Procedure. Replace spray

tip.

2)

Tighten pressure control knob set screw.

3)

Follow priming procedure under Start-up section of

owner’s manual.

4)

Check and tighten all high-pressure fittings.

5)

Follow Pressure Shut Down Procedure. Replace spray

tip.

6)

Replace valve.

7)

Refer to re-pack section of manual

8)

Follow Pressure Shut Down Procedure. Replace gun

filter.

1)

Follow Pressure Shut Down Procedure. Tighten

packing takeup nut. If still leaking, replace packings.

2)

Follow Pressure Shut Down Procedure. Replace

packings first. If still leaking, replace piston.

1)

Use smaller spray tip size.

2)

Increase pressure setting.

3)

Follow instructions under "Unit will not maintain

pressure or has low output".

4)

Reduce viscosity per manufacturer’s recommendations.

5)

Follow pressure shut down procedure. Remove and

clean filter.

1)

Replace ball or seat.

2)

Disassemble gun and clean.

3)

Adjust rear tension nut. If this doesn’t work examine ball

and replace if necessary.

1)

Replace worn or damaged parts.

2)

Clean or repair as required. Check gun filter.

1)

Replace valve ball.

1)

Clean spray tip. Clean or replace gun filter.

1)

Clean or replace gun filter. Clean spray tip.