15

Figure 14. Pump until clean solvent appears.

Warning: conductive metal containers must be used

when flushing flammable fluids through the system.

Always flush at low pressure with spray tip removed.

A metal part of the spray gun must be held firmly

against the grounded metal pail when flushing or

relieving pressure from the gun.

7) Pump solvent out by lifting both suction and return

hose out of the solvent. Turn pressure control to

minimum and open prime valve to release system

pressure. Lock trigger and cleanspray tip before re-

installing on gun.

Figure 15. Fluid is pumped out.

8) Follow above steps 1-7 using clean solvent to

completely flush unit.

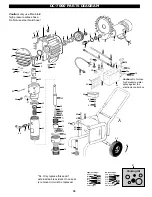

9) If changing paint types, ie: latex (water base) to oil

base, you would have to flush unit with clean mineral

spirits using above steps 1-7. This would prepare the

pump for the oil base paint. Water would have to be

used as a last flush if changing from oil base paints to

latex.

CLEANING INSTRUCTIONS

10) Ensure pressure control is turned to minimum and

all pressure is released. Open prime valve. Turn

pump OFF.

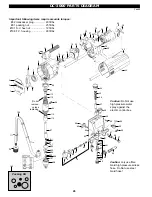

11) Unthread gun handle from gun body to access gun

filter. Remove filter and brush clean with appropriate

solvent. Inspect filter for pinholes, plugging, or other

damage. Replace if required. Re-install with “double

lip” end pointing up into gun. Lightly grease handle

threads (petroleum jelly, auto grease) and re-install

firm hand tight. Brush exterior of gun clean.

12) Remove intake screen on metal suction tube and

brush clean, re-install.

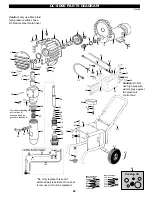

13) Storing unit for more than 3 days. If unit was

cleaned with an oily paint thinner such as varsol, the

unit is now ready for storage (after step 14). If unit

was cleaned with water or a strong thinner (ie. lac-

quer thinner) pump varsol (or mineral spirits) through

the entire system by repeating step 8. If varsol is not

available, drain all the solvent out of the hose, gun,

and pump. (Tungsten carbide parts in the valves

will corrode if left in water for long periods of

time).

14) Coil up electrical cord and spray hose, inspecting

both for signs of damage. Suggested minimum coil

size for 1/4" paint hose is 18 inches.

DO NOT COIL PAINT HOSE TOO TIGHTLY. THIS MAY

CAUSE KINKS, WHICH WEAKEN THE HOSE. A

PAINT HOSE WITH KINKS OR OTHER DAMAGE

SHOULD BE CONSIDERED UNSAFE AND BE RE-

PLACED IMMEDIATELY.

WARNING: DO NOT CLEAN THE SPRAY GUN UN-

LESS THE PRESSURE HAS BEEN RELEASED FROM

THE SYSTEM. SEE PAGES 3 & 4 FOR FURTHER

PRECAUTIONS.

Warning!