4

SAFETY PRECAUTIONS

16) Il ne faut jamais essayer de déplacer l'appareil en tirant sur le

tuyau. Il faut aussi éviter tout tortillement du tuyau.

17) Les enfants et le personnes n'ayant aucune

expérience avec ce genre de pulvérisateur doivent êtres

gardés à l'écart de l'appareil et du chantier de travail.

18) Quand on décharge des liquides inflammables il

faut utiliser des pots conducteurs en métal. Quand on

relâche la pression avec le pistolet, une partie métallique

du pistolet doit être en contact avec le pot en métal muni

de mise à la terre.

19) La protection de la gâchette réduit le risque

d'activement involontaire si on laisse tomber le pistolet ou s'il est

frappé par accident. Ne jamais utiliser le pistolet sans la

protection de gâchette.

20) Procédé à suivre avant tout travail d'entretien ou de

nettoyage.

1) Bloquer la gâchette avec le levier de verrouillage.

2) Placer l'interrupteur MARCHE-ARRÊT en position ARRÊT.

3) Débrancher le cordon électrique.

4) Ouvrir la vanne de mise à l'air libre pour relâcher la pression.

Gardez-la ouverte jusqu'au moment où vous êtes prêts à utiliser

l'appareil.

5) Enlever la buse.

6) Débloquer le levier de verrouillage de la gâchette.

7) Relâcher le reste de la pression en déchargeant avec le

pistolet dans un pot en métal. Quand on relâche la pression, une

partie métallique du pistolet doit être en contact avec le pot en

métal muni de mise à la terre. (Il n'est pas nécessaire d'utiliser un

pot avec mise à la terre pour des produits non inflammables,

comme par exemple le latex).

8) Ramener le levier de verrouillage en position bloquée.

Avertissement

Cet appariel est équipé d'un disjoncteur à Protection thermique.

En cas de surcharge, le disjoncteur automatique coupe le moteur

de la source d'alimentation.

• Toujours déconnecter le moteur de la source d’alimentation avant de

travailler sur l’appareil.

• Lorsque le disjoncteur coupe le moteur de la source d’alimentation

relâcher la pression en plaçant le clapet d’amorçage en position

“amorçage”.

• Placer l’interrupteur MARCHE-ARRÊT en position ARRÊT.

Attention: La cause de la surcharge doit être eliminée avant de

remettre le moteur en marche.

Données électriques.

Si l'on utilise un cordon de rallonge, veillez à ce qu'il soit à 3 fils (avec

mise à la terre) et avec certification CSA. Le calibre des fils doit être

suffisant pour l'ampérage qui est nécessaire pour que l'appareil

fonctionne. Voir le tableau ci-dessous indiquant les calibres minimuns

requis selon les différentes longueurs de la rallonge.

Il est important de garder le moteur propre et à l'abri de l'humidité.

L'isolation créée par la peinture sèche pourrait le surchauffer et

l'endommager.

Ne jamais enlever la broche de la mise à la terre car elle est essentielle

pour la slûreté du travail.

16) Do not pull on hoses to move equipment, DO NOT kink or bend

the hose sharply.

17) Keep children or anyone not familiar with airless spray

systems away from equipment and work area.

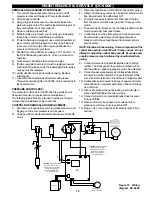

18) Conductive metal containers must be used when

flushing flammable fluids through the system. Always

flush at low pressure with spray tip removed. A metal part

of the spray gun must be held firmly against the grounded

metal pail when flushing or relieving pressure from the

gun.

19) Trigger guard helps reduce the risk of accidentally

triggering the gun if dropped or bumped. Do not use a spray gun

without a trigger guard.

20) Shut Down Procedure

Always follow Shut Down Procedure before starting any

troubleshooting, servicing or cleaning.

1) Engage the trigger safety lock in the locked position. Test the

trigger safety lock to ensure the lock is working properly.

2) Turn the On/Off switch to the Off position.

3) Unplug the electrical cord on the sprayer.

4) Open the prime valve to relieve pressure. Leave open until

ready to spray or test or clean.

5) Remove the spray tip.

6) Disengage the trigger safety lock.

7) Trigger the gun into a metal pail to relieve any remaining

pressure. A metal part of the spray gun should be held firmly

against the grounded metal pail when relieving the pressure from

the gun. (A grounded metal pail is not required for non-flammables

such as latex.)

8) Reset the trigger safety lock to locked position.

Warning

This unit is provided with a thermally protected Reset. If an

overload occurs, the thermally protected automatic reset discon-

nects the motor from the power supply.

• Always disconnect motor from power supply before working on

equipment.

• When thermally protected reset disconnects the motor from the

power supply, relieve pressure by turning priming valve to “prime”.

• Turn ON-OFF switch to OFF.

Caution: The cause of the overload should be corrected before

restarting.

Important: Read and understand these special safety precautions

before operating the unit.

Electrical requirements

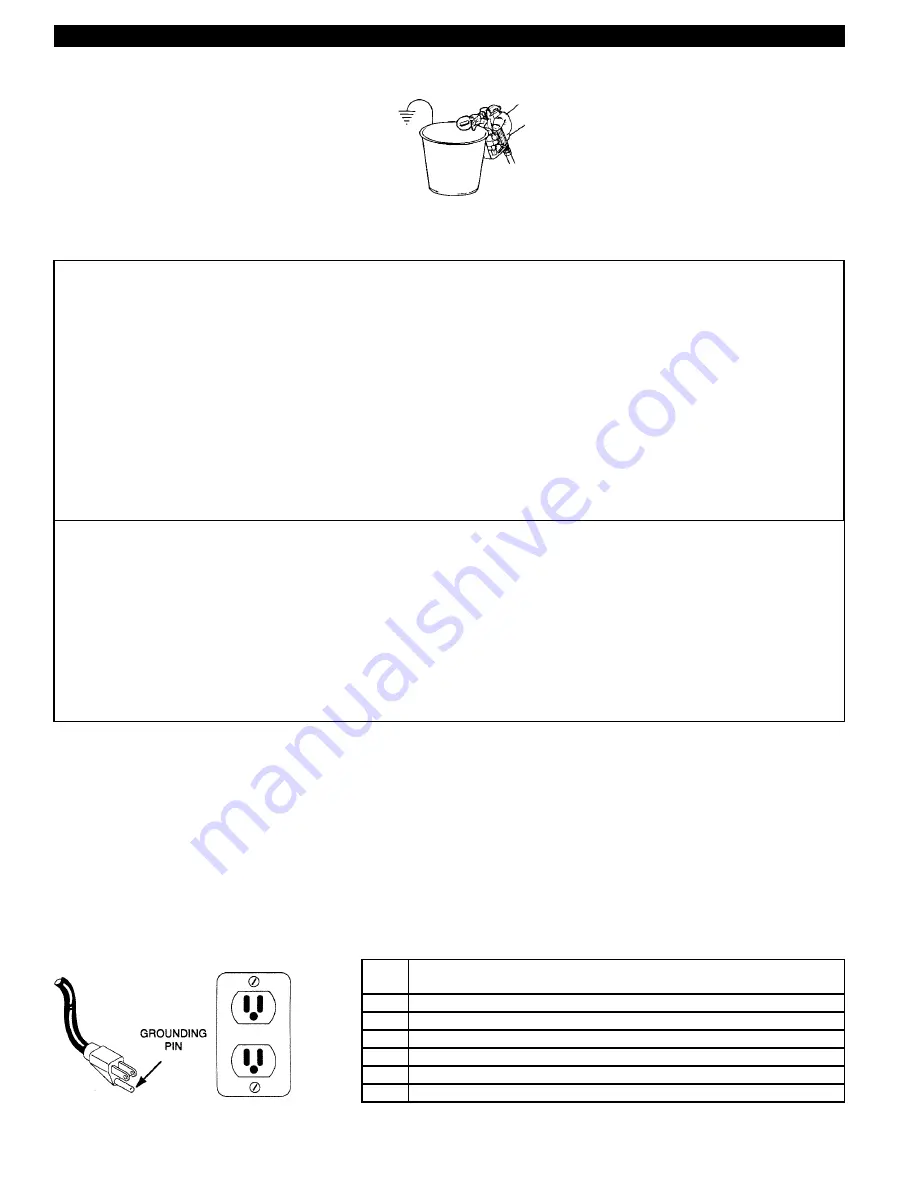

If an extension cord is used, make sure it is a 3 conductor type (has

grounding wire) and is CSA approved.Also make sure that its wire size

(AWG) is thick enough to carry the amperage your machine requires.

The chart below will show the minimum recommended AWG for specific

lengths. See next page for pump specifications.

Remember; keep the motor clean and dry. Paint acts as an insulator

and will cause overheating and/or motor damage.

Do not remove or bend grounding pin under any circumstances, it is

essential for safe operation.

Cord

Motor Amperage Rating

Length 0-5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

25 ft 16

16

16

16

16

16

14

14

14

12

12

12

12

12

12

12

50 ft 16

16

16

16

16

16

14

14

14

12

12

12

12

12

12

12

75 ft 16

16

16

16

16

16

14

14

14

12

12

12

12

12

12

12

100 ft 16

16

16

14

14

14

14

14

12

12

12

12

12

12

12

12

125 ft 16

16

14

14

14

12

12

12

12

12

12

12

12

12

12

12

150 ft 16

14

14

14

12

12

12

12

12

12

12

12

12

12

12

12

Minimum recommended AWG