3

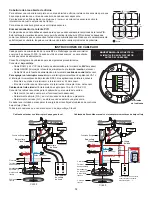

COVERAGE PATTERN

The CI-300 provides a 360° coverage pattern. Two lens patterns are available. The CI-300 provides up to 1200 square feet of coverage and

the CI-300-1 provides up to 500 square feet of coverage. The coverage shown represents walking motion at a mounting height of 8 feet. For

building spaces with lower levels of activity or with obstacles and barriers, coverage size may decrease.

8’ (2.4m)

10’ (3m)

12’ (3.7m)

0

40’

(12.2m)

30’

(9.1m)

20’

(6.1m)

10’

(3m)

40’

(12.2m)

30’

(9.1m)

20’

(6.1m)

10’

(3m)

0

8’ (2.4m)

10’ (3m)

12’ (3.7m)

0

20’

(6.1m)

15’

(4.6m)

10’

(3m)

5’

(1.5m)

0

20’

(6.1m)

15’

(4.6m)

10’

(3m)

5’

(1.5m)

24 ft

7.3m

IW

P

Top View @ 8ft

Top View @ 8ft

C-300 Coverage Pattern (Extended Range Lens – Standard)

C-300 Coverage Pattern (High Density Reduced Range Lens)

Side View

Side View

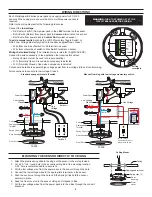

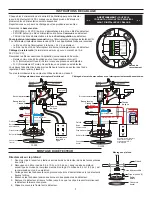

Using an Octagonal J-Box

1. Pull the low voltage wires from the power pack into the J-Box through the

conduit knockout.

2. Connect the low voltage wires to the appropriate terminals on the sensor.

3. Loosen the appliance mounting screws attached to the J-Box

4. Align the sensor in the J-Box so that the mounting screws on the box match

the key holes on the sensor’s rear housing.

5. Push the sensor up into the J -Box and twist it so that the mounting screws are

seated in the keyhole slots.

6. Tighten the two screws to secure the sensor to the J-Box.

7. Snap the front cover onto the sensor.

Rear

Housing

Depluggable

Terminal

4" Octagonal J-Box

(at least 1.5" deep)

Front

Cover

Ceiling

Screws

J-Box Mount

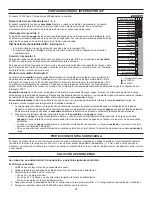

SENSOR ADJUSTMENT

This unit is pre-set for basic operation as described in this guide.

Adjustment is optional.

The sensors are factory preset to allow for quick installation in most applications.

Verification of proper wiring or coverage, or customizing the sensor’s settings

can be done using the following procedures. To make adjustments, open the

Front Cover by pulling on the cover tab.

There is a 30 second warm-up period when power is first applied.

Before making adjustments, make sure the office furniture is installed, lighting

circuits are turned on, and the HVAC systems are in the overridden/on position.

VAV systems should be set to their highest airflow. Set the DIP switches to the

desired settings. See

DIP Switch Setting

, next page.

To Test Occupancy Sensors

1. Ensure the Time Delay is set for

Test Mode*

using the “Test Mode/20 minutes” setting. (DIP switches 1,2, & 3 are

OFF

).

2. Ensure that the Light Level is at default (maximum). See the Light Level Feature section of this document for instructions.

3. Remain still. The red LED should not flash. The lights should turn off after 5 seconds. (If not, see

Troubleshooting

.)

4. Move about the coverage area. The lights should come on.

5. When testing and adjustment are complete, reset DIP Switches and Light Level to the desired settings, and replace the cover on

the sensor.

* Test Mode

is a temporary state that starts when you first set the sensor’s DIP switches for the “Test Mode/20 minutes” (switches 1, 2,

3,

OFF

). If you need to invoke the

Test Mode

and the DIP switches are already set for Test Mode/20 minutes, toggle DIP switch 1

ON

then back to the

OFF

position. This provides a 10 minute test period. During the test period, the Time Delay is only 5 seconds.

.H\KROHVORWV

IRUPRXQWLQJWR

RFWDJRQDOER[

'RXEOHJDQJ

PXGULQJ

PRXQWLQJKROHV

/LJKWOHYHO

SXVKEXWWRQ

',3

VZLWFKHV

3,5OHQV

21

(&(

3,5$FWLYLW\

/('5HG