USER MANUAL

Manure spreader MKL

50

7.2.3 Servicing and adjustment of the hydraulic brake system

During the use of the tractor manure spreader, it is necessary to check the tightness of the hydraulic

brake system and condition of its elements, to periodically lubricate the marked points.

The adjustment of the brakes shall be performed when:

•

the brake blocks are worn-out. The space between the brake blocks and drum increases, causing

the impairment of braking efficiency;

•

the wheels are braked not simultaneously and not uniformly.

When the brakes are adjusted correctly, the braking force (the sum of braking forces acting upon the

wheels being braked) should account for min 27 % of the permissible total mass of the semi-trailer when

braking with the working brake, and the braking force (the sum of braking forces acting upon the wheels

being braked) should account for min 16 % of the permissible total mass of the semi-trailer when braking

with the hand-brake. Both wheels of one axle should brake uniformly. The difference of the braking forces

between the left and right sides of the semi-trailer should not exceed 30 %.

The adjustment of the brakes shall be performed only after the adjustment of the bearings of the

wheel hub, by changing the brake shaft's brake lever torque or angle of brake lever in respect of the shaft.

For this purpose, it is necessary:

•

place protection wedges (blocks) under the wheel opposite to the one being adjusted;

•

insert a jack under the axle, at the marked place, and lift the wheel;

•

while rotating the wheel, also turn the adjustment bolt 3 (Figure. 7.16) until the braking blocks

touch the drum.

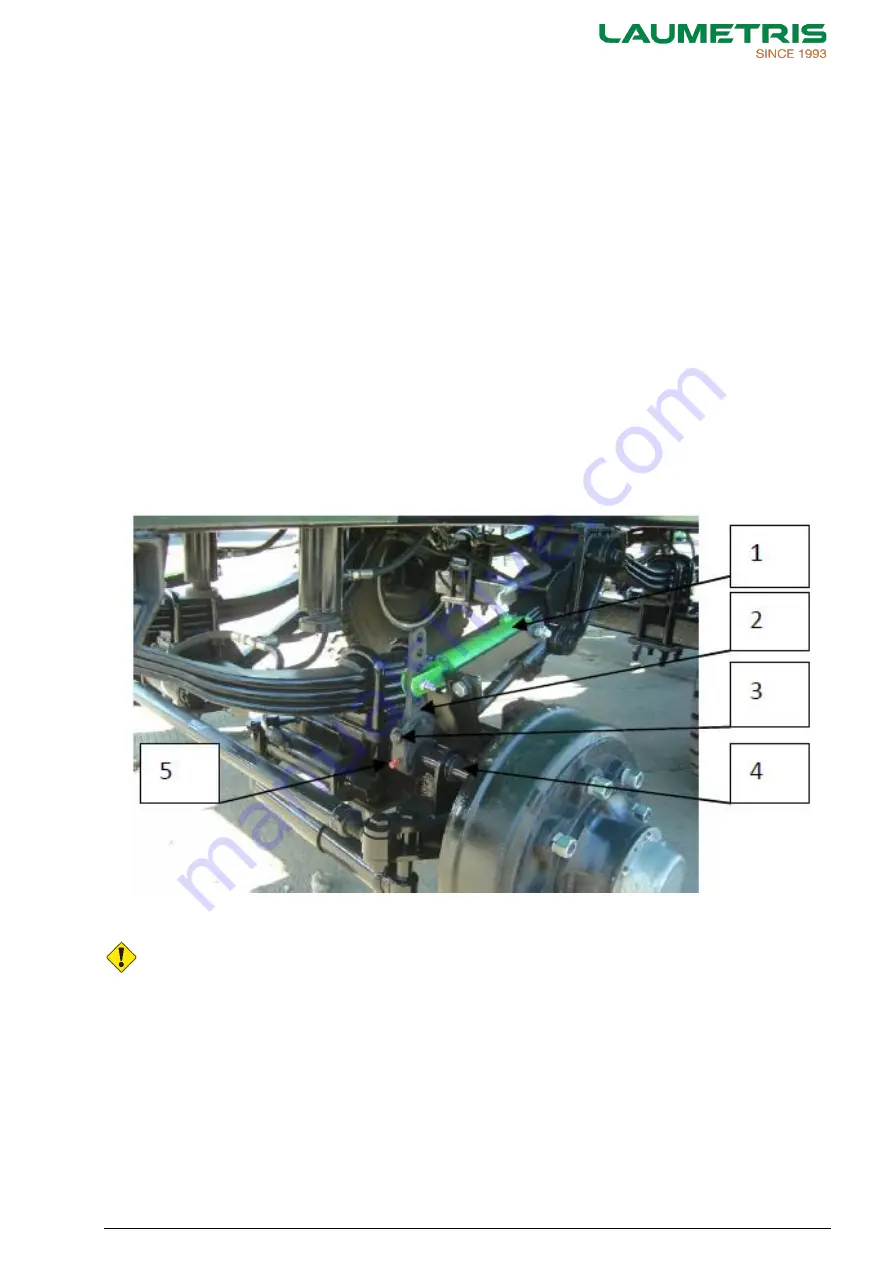

Fig. 7.16. Elements of the braking system. 1 -braking hydraulic cylinder; 2 - leveler; 3 - adjustment bolt; 4 - cam shaft; 5 -

lubrication point.

ATTENTION! When performing repair works of the hydraulic and pneumatic systems, make sure

that the system is not under pressure.

7.3 Hydraulic system

It is necessary to ensure that lubricant in the hydraulic system of the tractor and in the hydraulic

system of the manure spreader is of the same grade. It is prohibited to use lubricant of different grades.

The hydraulic system of the manure spreader must be tight. Check tightness by activating for a short

time the body tipping hydraulic cylinder. If any leak of lubricant is found, tighten up the connections. If this

does not help, replace the hoses or connections with new ones. If an assembly is mechanically damaged, it

must be required with a new one. The connecting elements of the hydraulic system must be clean.