10

Dispenser Setup

Failure to disconnect the motor power supply will dam-

age the carbonator motor, the pump and void the war-

ranty

F

ATTENTION

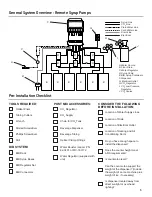

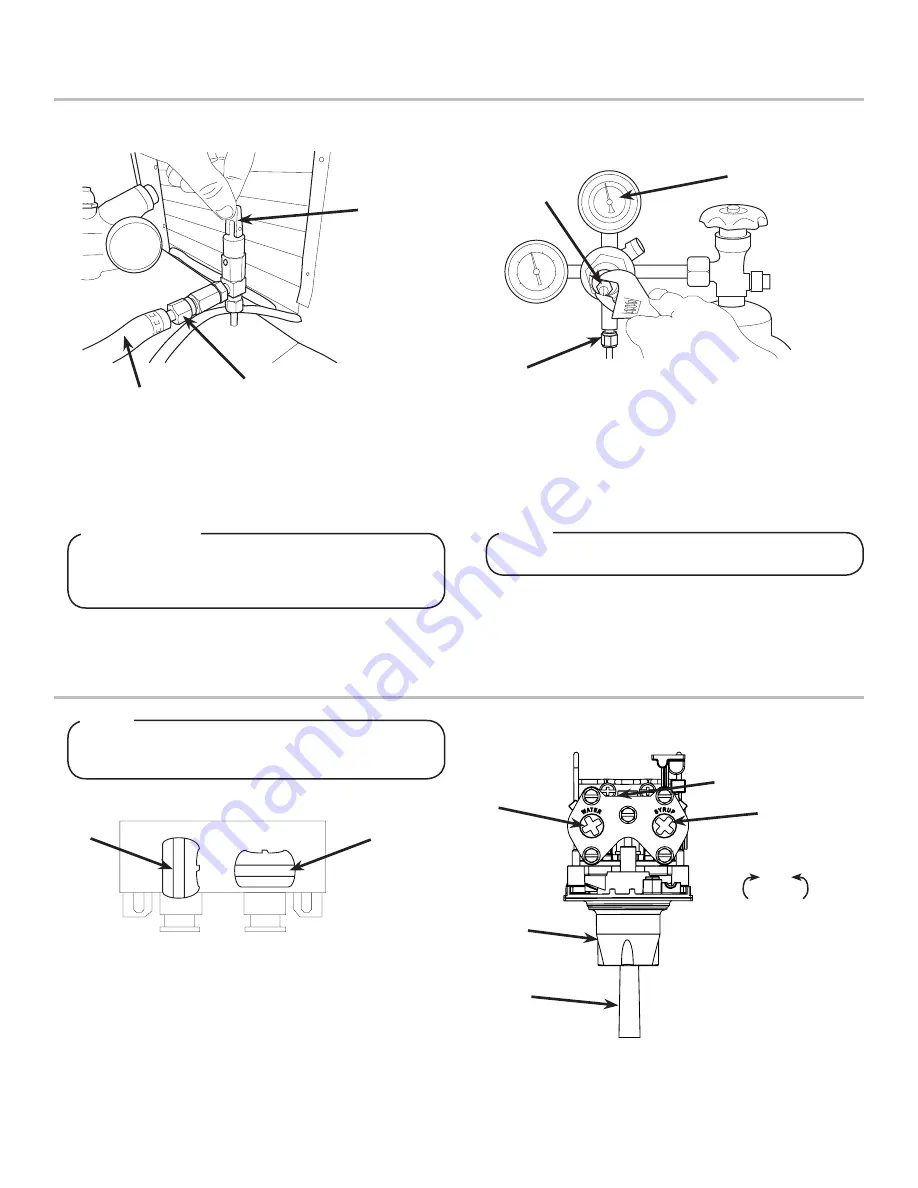

A. Relief Valve (Open)

B. CO

2

Inlet

C. CO

2

Line

A

B

C

1.

Purge water to fill carbonator tank by opening carbonator

relief valve. Close relief valve once water comes out.

2.

Activate each valve until a steady flow of water is achieved.

3.

Turn power off.

4.

Unplug the Pump Motor Connector from the control box. Use

the wiring diagram either on the unit control box or in the

back of this manual for reference.

5. Turn on CO

2

at the source then, using a screwdriver, adjust

the high pressure regulator at the source to 110 Psi (0.758

MPa) then tighten locknut with wrench.

6. Adjust both of the low pressure regulators on the regulator

manifold to 75 Psi (0.517 MPa) then tighten locknut with

wrench.

7. Activate each valve until gas-out is achieved.

8. Plug the Pump Motor Connector back into the control box.

Pump Motor will run for a few seconds to fill carb tank

NOTE

9. Turn power on.

10.

Activate each valve until a steady flow of carbonated water is

achieved.

A. Regulator Adjustment Screw

B. Adjust to 110 Psi (0.758 MPa)

C. Wrench

A

B

C

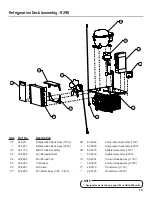

Adjust Water Flow Rate & Syrup/Water Ratio - LEV

Do not set flow rates or dispense from the unit until

after a complete ice bank is established.

NOTE

1.

Close syrup shut-off at mounting block for first valve.

A

B

Increase

Decrease

C

E

A. Flow Control, Water

B. Flow Control, Syrup

C. Nozzle (Diffuser inside)

D. Mounting Block (not shown)

E. Soda Lever

D

2.

Using a Lancer brix cup verify water flow rate (5 oz. in 4

sec.). Use a screwdriver to adjust if needed.

A

B

A. Plain Water ON

B. Syrup Closed

Содержание Delta-600 R-290

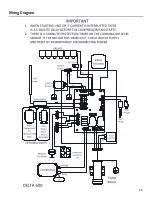

Страница 23: ...23 Wiring Diagram...