3

IMPORTANT SAFETY INSTRUCTIONS

• The dispenser is for indoor use only

• This appliance is intended to be used in commercial

applications such as restaurants or similar.

• This appliance

should not be used by children or infirm

persons without supervision.

• This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a

person responsible for their safety.

• This appliance is not a toy and children should be advised not to

play with the appliance. This appliance can be used by children

aged from 8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the

hazards involved.

• Cleaning and user maintenance shall not be performed by

children without supervision.

• The min/max ambient operating temperature for the dispenser is

65°F to 105°F (18°C to 40°C). Do not operate unit below minimum

ambient operation conditions.

• Should freezing occur, cease operation of the unit and contact

authorized service technician.

• The maximum tilt for safe operation is 5°. This appliance must be

installed and serviced by a professional.

!

Intended Use

•

Follow all local electrical codes when making connections.

• Check the dispenser name plate label, located behind the splash

plate for the correct electrical requirements of unit.

DO NOT

plug

into a wall electrical outlet unless the current shown on the serial

number plate agrees with local current available.

• Each dispenser must have a dedicated electrical circuit.

• DO NOT

use extension cords with this unit.

• DO NOT

‘gang’ together with other electrical devices on the

same outlet.

• DO NOT

locate multiple portable socket-outlets or portable power

supplies at the rear of the appliance.

• WARNING:

Always disconnect electrical power to the unit to

prevent personal injury before attempting any internal

maintenance.

• The re-settable breaker switch should not be used as a substitute

for unplugging the dispenser from the power source to service the

unit.

•

Only qualified personnel should service internal components of

electrical control housing.

• WARNING:

Make sure that all water lines are tight and units are

dry before making any electrical connections

• If this dispenser is installed in an area that is susceptible to more

than 10% variation of the nominal line voltage, consider installing

a surge protector or similar protection device.

F

Electrical Warning

• WARNING:

Carbon Dioxide (CO

2

) is a colorless, noncombustible

gas with a light pungent odor. High percentages of CO

2

may

displace oxygen in the blood.

• WARNING:

Prolonged exposure to CO

2

can be harmful.

Personnel exposed to high concentrations of CO

2

gas will

experience tremors which are followed by a loss of consciousness

and suffocation.

• WARNING:

If a CO

2

gas leak is suspected, immediately ventilate

the contaminated area before attempting to repair the leak.

• WARNING:

Strict attention must be observed in the prevention of

CO

2

gas leaks in the entire CO

2

and soft drink system.

5

Carbon Dioxide (CO

2

)

•

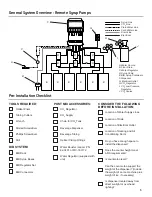

This system uses a flammable refrigerant under pressure. Do not

tamper with it. Contact qualified service personal before disposal.

• In order to minimize the risk of possible ignition due to

incorrect parts or improper service, only factory authorized

personnel should perform service on the appliance and its

component parts

• Do not store explosive substances such as aerosol cans with a

flammable propellant in this appliance.

• Replace component parts with like components. Only use

genuine Lancer parts or parts certified by Lancer.

• Do not damage the refrigerant circuit.

H

Refrigerant Warning

•

Provide an adequate, potable water supply. Water pipe

connections and fixtures directly connected to a potable water

supply must be sized, installed, and maintained according to

federal, state, and local codes.

• The water supply line must be at least a 3/8 inches (9.525 mm)

pipe with a minimum of 25 psi (0.172 MPa) line pressure. Water

pressure below

25 psi (0.172 MPa) will require the use of a water

booster, (82-3401 or MC-163172). For proper carbonation water

pressure exceeding 65 psi (0.448 MPa) must be reduced by way

of a water regulator (18-0253/02).

•

Use a filter in the water line to avoid equipment damage and

beverage off-taste. Check the water filter periodically, as required

by local conditions.

• CAUTION:

The water supply must be protected by means of an air

gap, a backflow prevention device (located upstream of the CO

2

injection system) or another approved method to comply with NSF

standards. A leaking inlet water check valve will allow carbonated

water to flow back through the pump when it is shut off and

contaminate the water supply.

• CAUTION:

Ensure the backflow prevention device complies with

ASSE and local standards. It is the responsibility of the installer to

ensure compliance.

!

Water Notice

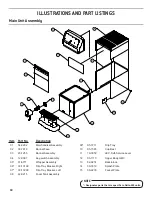

Содержание Delta-600 R-290

Страница 23: ...23 Wiring Diagram...