7

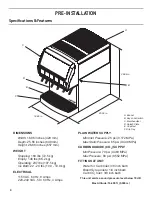

Dispenser Installation

The installation, and relocation if necessary, must

be carried out by qualified personnel with up-to-date

knowledge and practical experience, in accordance

with current regulations.

NOTE

NSF listed units must be sealed to the counter or use

legs provided.

NOTE

1. The dispenser is designed to be installed either permanently

to counter or placed on a counter using the legs (included in

the Lancer kit, PN 82-1704).

2. When the dispenser is to be permanently bolted to the

counter top, the dispenser base must be sealed to the

counter top with a bead of clear silicone caulk or sealant

which provides a smooth and easily cleanable bond to the

counter.

3. Once the dispenser is installed to the counter or placed on

the counter using legs provided, remove the cup rest, splash

plate, and valve shroud.

4. Connect drain tube to the drain fitting located on the bottom

of the drip tray and secure drain tube with clamp.

5.

Route the drain line to designated floor drain.

6. Remove the bonnet screw from the top of the unit and lift the

bonnet to remove from the dispenser.

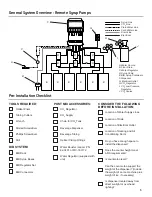

7. Route appropriate tubing from the syrup pump location to the

syrup inlets located behind the splash plate. Connect tubing

to inlets using the oetiker pliers and fittings. Repeat for all

syrup connections.

11. Using a conductivity meter, measure the electric conductivity

of the distilled water mixture.

Carefully read this before filling the water bath tank.

In order to optimize the maximum performance of the

dispenser, the following MUST be adhered to:

!

CRITICAL

- to maximize performance

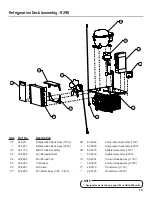

12.

Remove yellow cap from the water bath fill hole and insert

and insert a funnel into the fill hole.

13. Carefully pour the distilled water mixture into the water bath

tank until water flows out of the overflow tube at the front

of the unit. Then replace yellow cap (Repeat steps 7-8 if

needed)

8. Route appropriate tubing from the water source to the

carbonator pump inlet at the unit, and connect tubing to

water source.

For proper function of the electronic ice bank control

the total dissolved solids (TDS) measurements should

be 300-500 ppm.

!

ATTENTION

A

B

C

A. Bucket

B. Distilled Water

(approx. 5.4 gal)

C. Baking Soda

(approx. 1/8 oz)

The E.C. measurement of the distilled water mixture

must be between 100 and 300 uS/cm. Below 100 uS/cm,

the compressor will not work properly and above 300

uS/cm could cause the lines to freeze.

!

ATTENTION

9.

Insert water line into a large bucket, and fill with approx. 5.4

gallons (20.4 L) of distilled water.

10.

Add 1/8 oz (4 g) of baking soda to distilled water and stir.

The water bath compartment must be filled with water

before plugging in the unit, otherwise the compressor

deck and condenser fan may not operate properly. DO

NOT use RO or purified water.

!

ATTENTION

Make sure the top of overflow tube is not covered so

that the water from the water bath tank cannot escape.

NOTE

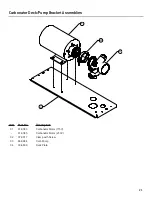

A

B

C

A. Oetiker Pliers

B. Fitting

C. Tubing

D. Syrup/Water/CO

2

Inlet

D

14.

Using tubing cutters, cut water supply line and install “U”

fitting,

(PN 01-2128/01).

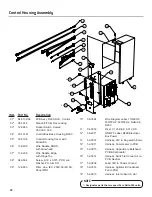

A

B

C

A. Line to Water Source

B. Line To Plain Water Inlet

C. Line To Carb Water Inlet

D. “U” Fitting

D

Содержание Delta-600 R-290

Страница 23: ...23 Wiring Diagram...