25

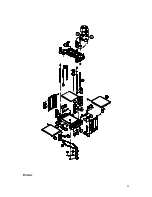

Figure 15: Auto Lock

It is advisable to rotate all inserts at the same time to maintain

consistent cutting. However, if one or more knife inserts develops a

nick, rotate only those inserts that are affected. Each knife insert has

an etched reference mark so you can keep track of the rotation.

Torque each screw to 52-60 in/lbs

.

IMPORTANT:

When removing or rotating inserts, clean saw dust from

the screw, the insert, and the cutterhead platform. Dust accumulation

between these elements can prevent the insert from seating properly

and may affect the quality of the cut.

Before installing each screw, lightly coat the screw threads with

machine oil and wipe off any excess. Securely tighten each screw which

holds the knife inserts before operating the jointer!

Make sure all knife insert screws are tightened securely. Loose inserts

can be propelled at high speed from a rotating cutterhead, causing

injury.

Torque each screw to 52-60 in/lbs.

Conveying Rollers

Keep rollers clean to help prevent slippage of material. Be careful not

to contact cutterhead knives as they are very sharp!

Turn planer OFF and disconnect power before performing any

maintenance or adjustments!

Carriage thickness adjustment chain tension

Auto Lock,

cutterhead

Содержание PX12

Страница 1: ...OWNERS S MANUAL PX12 Planer Quadtec I Cutterhead Lagunatools com...

Страница 29: ...29 EXPLODED VIEWS Cutterhead Drivetrain...

Страница 30: ...30 Table Lift...

Страница 31: ...31 Motor...

Страница 32: ...32 Wiring Diagram PX12 PARTS LIST...

Страница 38: ...38 021121...