12.

Ram pusher returns to its fully retracted up position.

If multiple crimps are being made with the same

fitting, the retraction stop can be released and

tightened again while ram is extended. This will

limit the amount of retraction and advancement time

of the ram for the next crimp.

13.

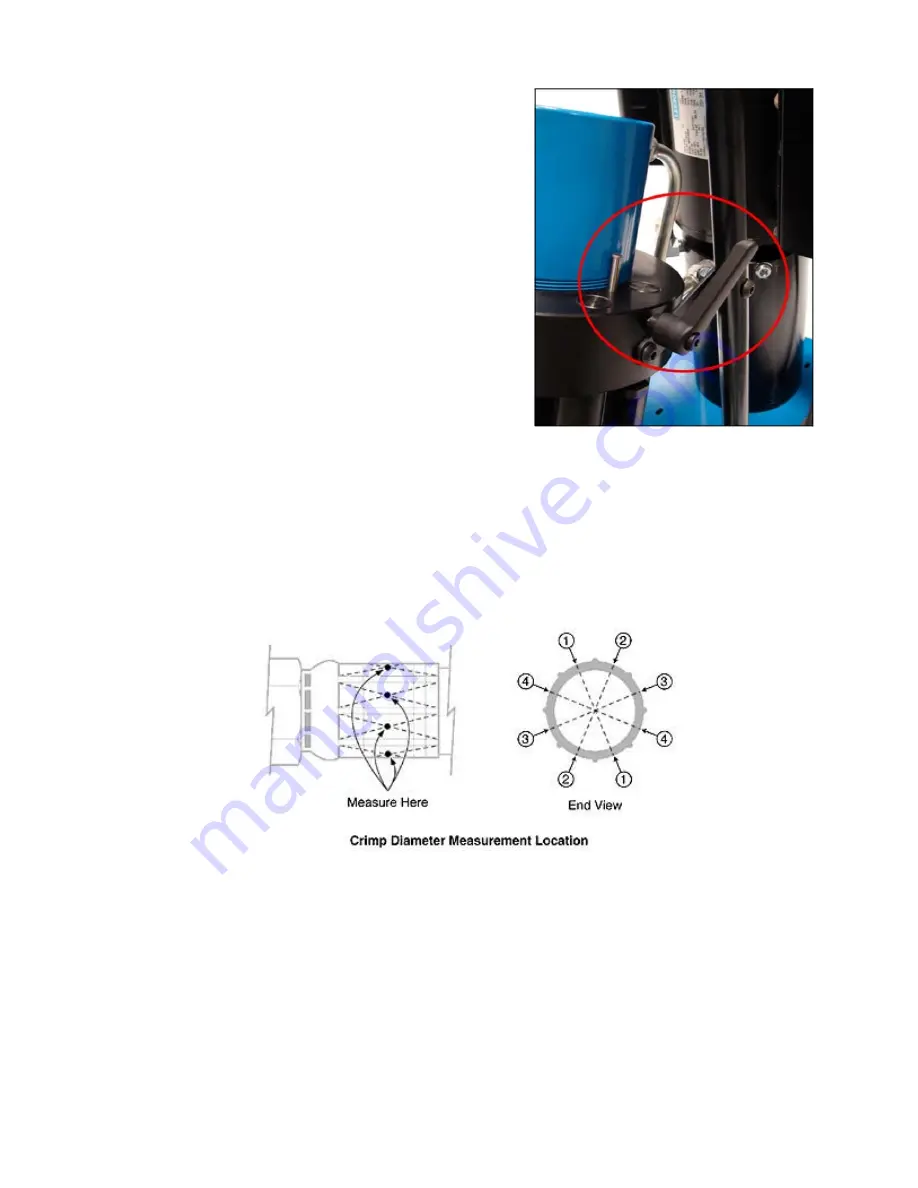

When the crimp cycle is finished and the ram pusher has retracted, manually remove the pusher

donut and pull the coupling out of the die set. The ram pusher can also be removed as

necessary depending on the size of the fitting being crimped. Using dial calipers or a

micrometer, measure the crimp diameter on the mid-point of the flat surface and of the crimped

coupling where die faces have met the coupling. Take four (4) measurements around the

coupling and average the measurements. Refer to the Kurt Hydraulics crimp specification to

confirm crimp diameter is in tolerance.