CRIMPING

Once the hose and coupling are prepared, you are ready to crimp with the KH60 crimper.

Insure that you have the following:

Verify all components are available.

Properly prepared the hose and coupling.

Insure the interior of the hose is free of cuttings, dirt or other debris.

Obtain the Kurt Hydraulics crimp specifications.

1.

Consult the Kurt Hydraulics crimp specification for the KH60 to determine the proper die set

for the chosen hose and coupling combination.

2.

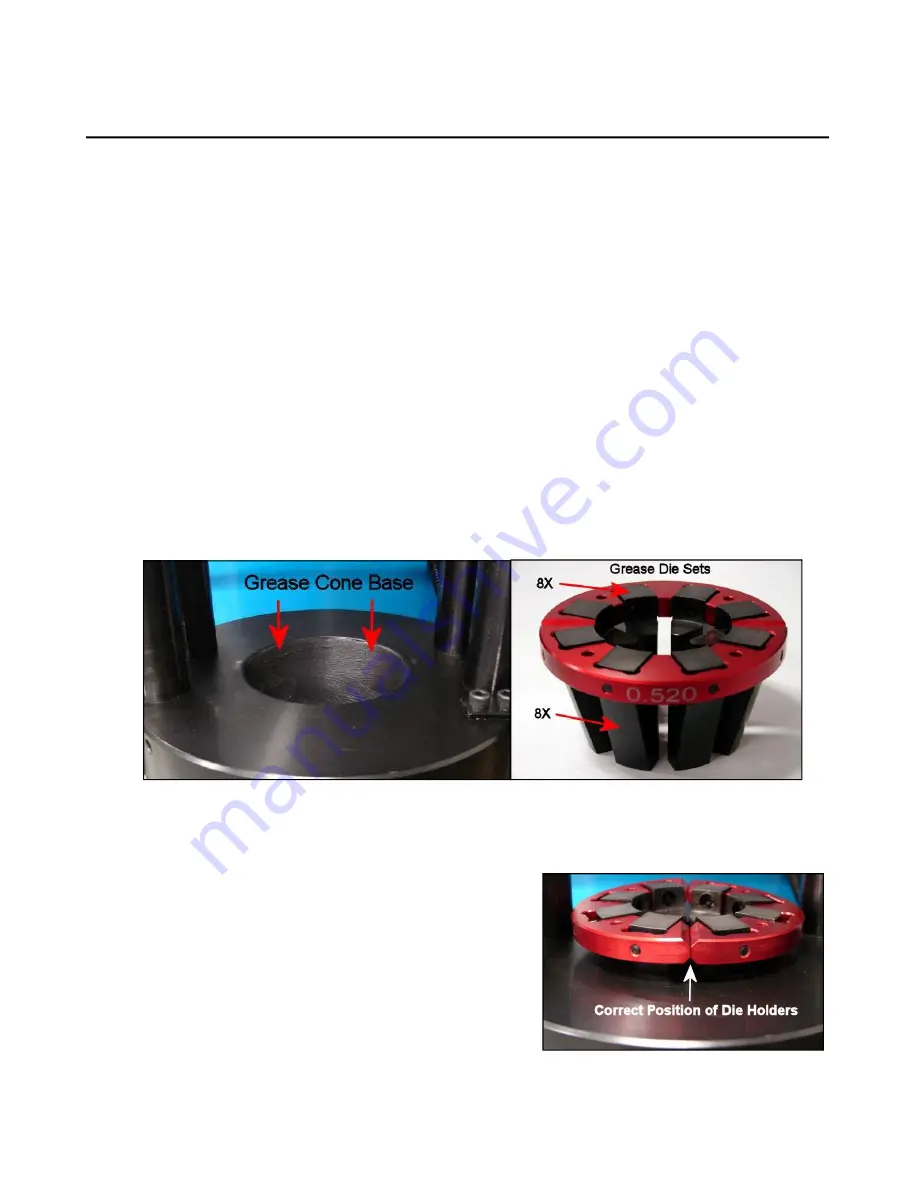

Lubricate the cone base and segments for the die set with the supplied anti-seize or equivalent

high pressure molybdenum grease. Re-apply grease regularly, especially when wearing

surfaces on cone base and fingers appear shiny. Kurt Hydraulics recommends applying more

grease at least every 10 crimps, or after periods of non-use.

CAUTION:

Failure to lubricate die sets and the cone base regularly will cause damage to the die

set and could permanently damage the crimper.

3.

Place the die set in the cone base. Verify that the dies

are properly aligned and that the die holders do not

overlap. Kurt Hydraulics recommends placing the

seam between the two die holders in front of the

crimper in view of the operator.