-24-

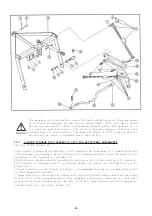

In addition, with this combination, the

stops (E)* must be fitted and correctly

adjusted on the front frame (F) in order

to protect the PTO shaft (T) from being

subject to excessive angles and to avoid

the sliding tubes butting together.

Therefore, when first mounting the

machine, proceed as follows :

- Connect transmission (T)

- Progressively lift the combined ma-

chine up to the maximum overlap of the

transmission tubes, at the same time

ensuring that there is always a safety

clearance (X) of 1-2 cm (1/2"-1").

- Position and lock the stops (E) on the

front frame (F) so that they come into

contact with the lower arms (G) and

therefore limit the lifting height.

The manoeuvrability of the rear hydraulic linkage can then be made with total safety.

* Set of stops : No 1207 690

The gearbox is fitted with a rear PTO shaft which turns at the same speed

(rotational frequency) as the tractor drive shaft. This rear drive shaft

should not be used to drive a secondary machine while the gearbox is in

its neutral position (due to the risk of gearbox damage resulting from

inefficient oil circulation). The rear PTO shaft (1 3/8" 6 spline profil)

should not be used to transmit more than 50 HP.

c) Maintenance of the linkage

Periodically grease the different pivot points equipped with grease nipples (ten

grease nipples).

When parking the combined unit (EL 100 N seed drill, for example) make sure

that the additional implement is lowered first.

IV 3-POINT SEMI-AUTOMATIC FRONT LINKAGE

(no 1207110 for cat. II,

no 1207120 for cat. III)

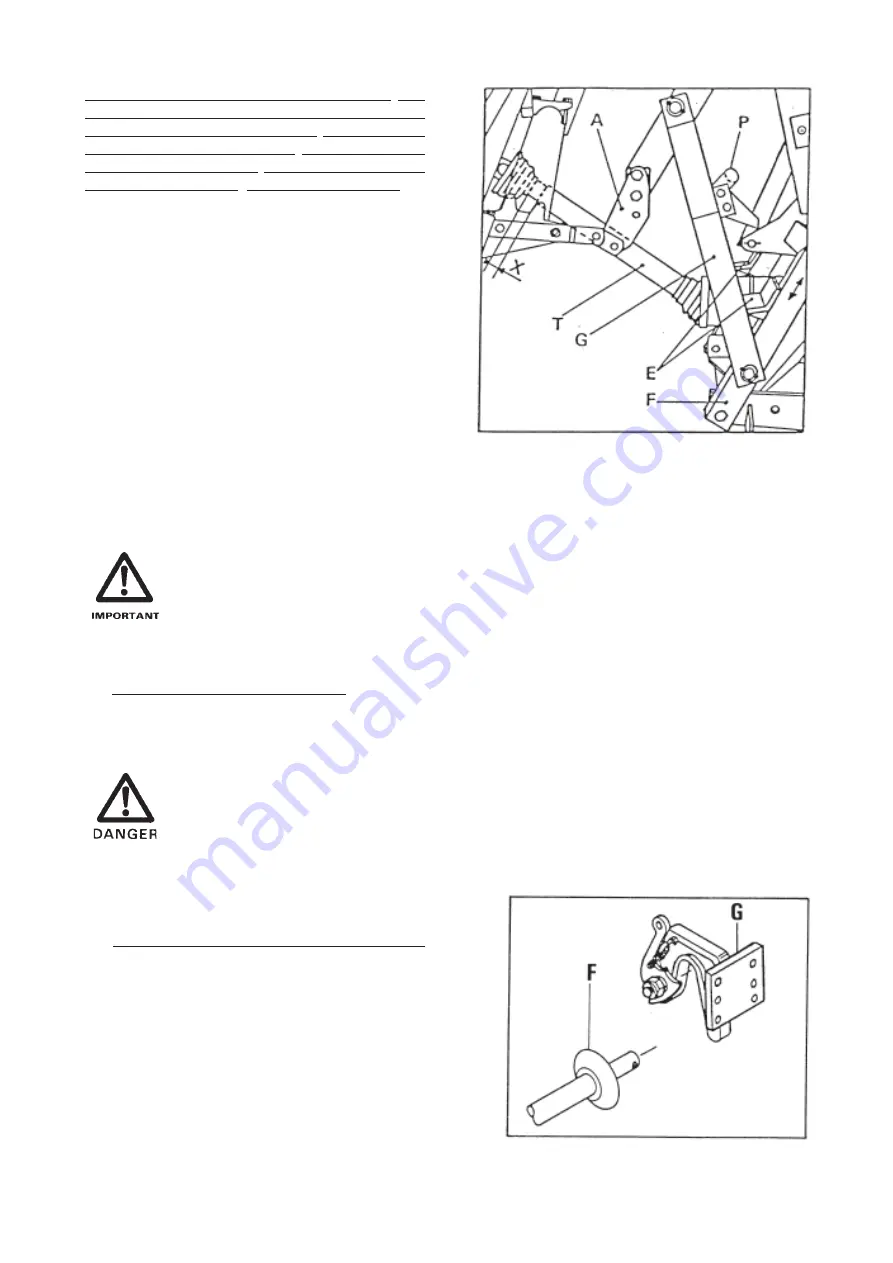

The semi-automatic linkage includes an

attachment bar (F) and two hooks (G). Fit

the attachment bar to the lower link arms

of the tractor and the hooks (G) to the

3-point frame in place of the lower

standard attachment brackets.

Содержание EL 100 N

Страница 1: ...ASSEMBLY OPERATOR S MANUAL EL 100 N POWER TILLER N 95458 A GB 12 1999...

Страница 10: ...8...

Страница 18: ...16...