KFU 2-/4-

126

The positioning is started by a start command from a signal source (e.g. digital input)

which must be assigned to the parameter

Start Positioning of Axle

37

. The signal

source can be selected from the operation modes for digital inputs described in chap-

ter "Digital inputs".

The positioning starts on condition that the

Actual frequency

241

of the output signal

is smaller than the value entered in parameter

Positioning frequency

471

. Due to a

stopping behavior, the actual frequency drops below the positioning frequency.

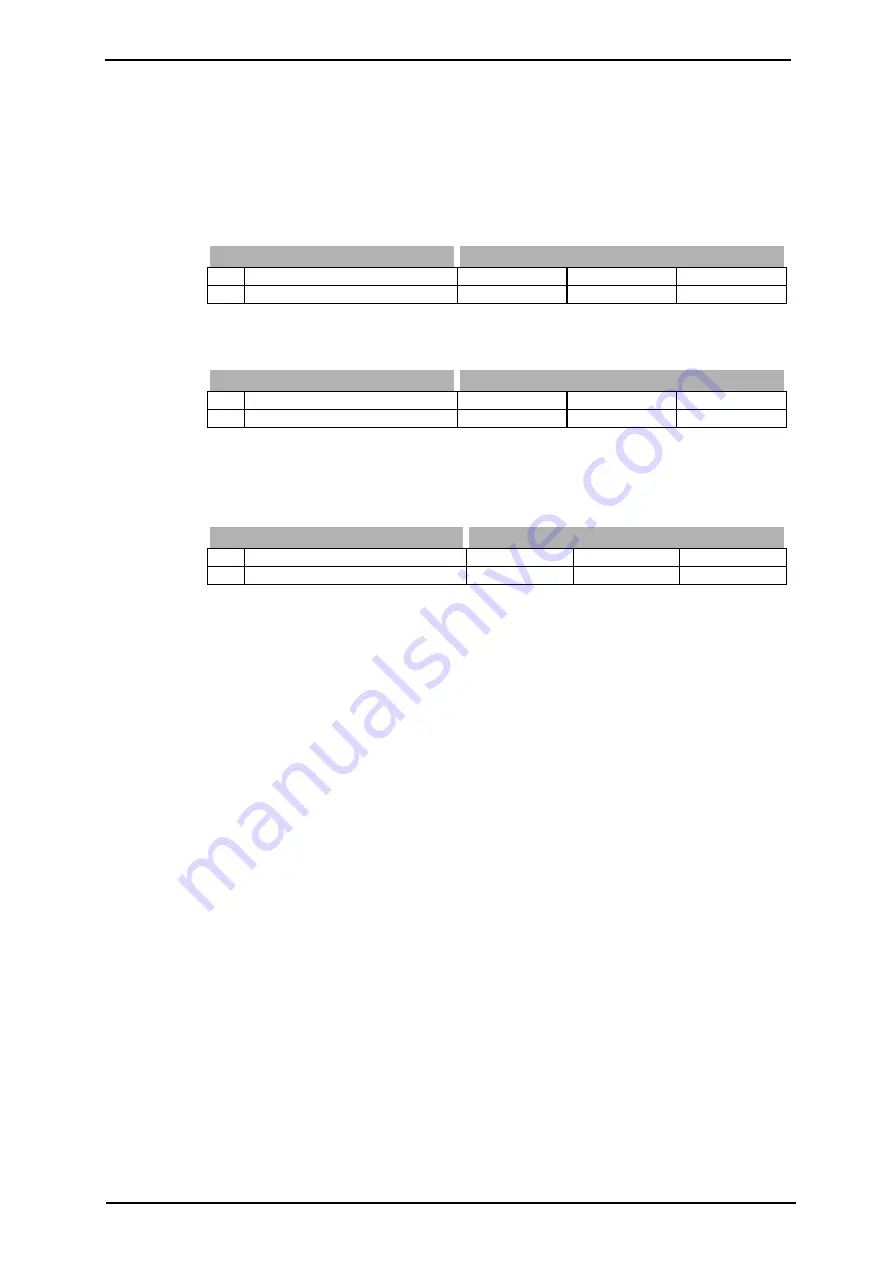

Parameter

Settings

No.

Description

Min.

Max.

Fact. sett.

471 Positioning frequency

1.00 Hz

50.00 Hz

50.00 Hz

Via the parameter

Max. positional error

472

, the maximum permissible deviation

from the

Reference orientation

469

can be set.

Parameter

Settings

No.

Description

Min.

Max.

Fact. sett.

472 Max. positional error

0.1°

90.0°

3.0°

Via parameter

Time constant positioning controller

479

, the time constant for control-

ling the positional error can be set. The value of the time constant should be in-

creased if oscillations of the drive around the reference orientation occur during the

positioning.

Parameter

Settings

No.

Description

Min.

Max.

Fact. sett.

479 time constant positioning contr.

1.00 ms

9999.99 ms

20.00 ms

To make sure that the set position is maintained if a load torque is applied, a stopping

behavior should be selected for parameter

Operation mode

630

which impresses a

starting current either permanently when the drive is at a standstill or for the stopping

time.

The status message “60 - Target Position Reached“ which is displayed when the

reference orientation is reached can be assigned to a digital output. The message is

output on the following conditions:

Operation mode 2 (axle positioning) for parameter

Operation mode

458

is se-

lected.

The controller enable signal at digital inputs S1IND/STOA and S7IND/STOB is

switched on.

Start Positioning of Axle

37

is activated

.

The speed sensor monitoring is activated, i.e. operation mode 2 (error message)

for parameter

Operation mode

760

of the speed sensor monitoring is selected.

Operation mode 1004 or 1104 (quadruple evaluation with reference impulse) is

selected for the speed sensor input.

The

actual frequency

241

is smaller than 1 Hz.

The deviation of the current position from the reference orientation is smaller than

the

max. orientation error

472

.

The current position after

Start Positioning of Axle

37

is recognized by the frequency

inverter as follows:

During commissioning, after switching on the frequency inverter, a search mode

is performed for 3 rotations at a rotational frequency of 1 Hz in order to detect the

reference signal. As soon as the reference signal was recognized twice, the drive

is positioned to the

Reference orientation

469

.

If the motor was already rotating before axle positioning was enabled, the posi-

tioning to the

Reference orientation

469

is performed without search mode be-

cause the position of the reference point was already detected by the frequency

inverter.