KFU 2-/4-

102

9.2

Further motor parameters

In particular the field-oriented control requires the determination of further data which

cannot be read off the rating plate of the 3-phase machine for the precise calculation

of the machine model. In the course of the guided commissioning, the parameter

identification was carried out to measure the further motor parameters.

9.2.1 Stator

Resistance

The resistance of the stator winding is measured during the guided commissioning.

The measured value is saved as a phase value in parameter

Stator resistance

377

and is 3 times smaller than the winding resistance in delta connection.

By default, the equivalent stator resistance of a standard motor is entered to match

the reference output of the frequency inverter.

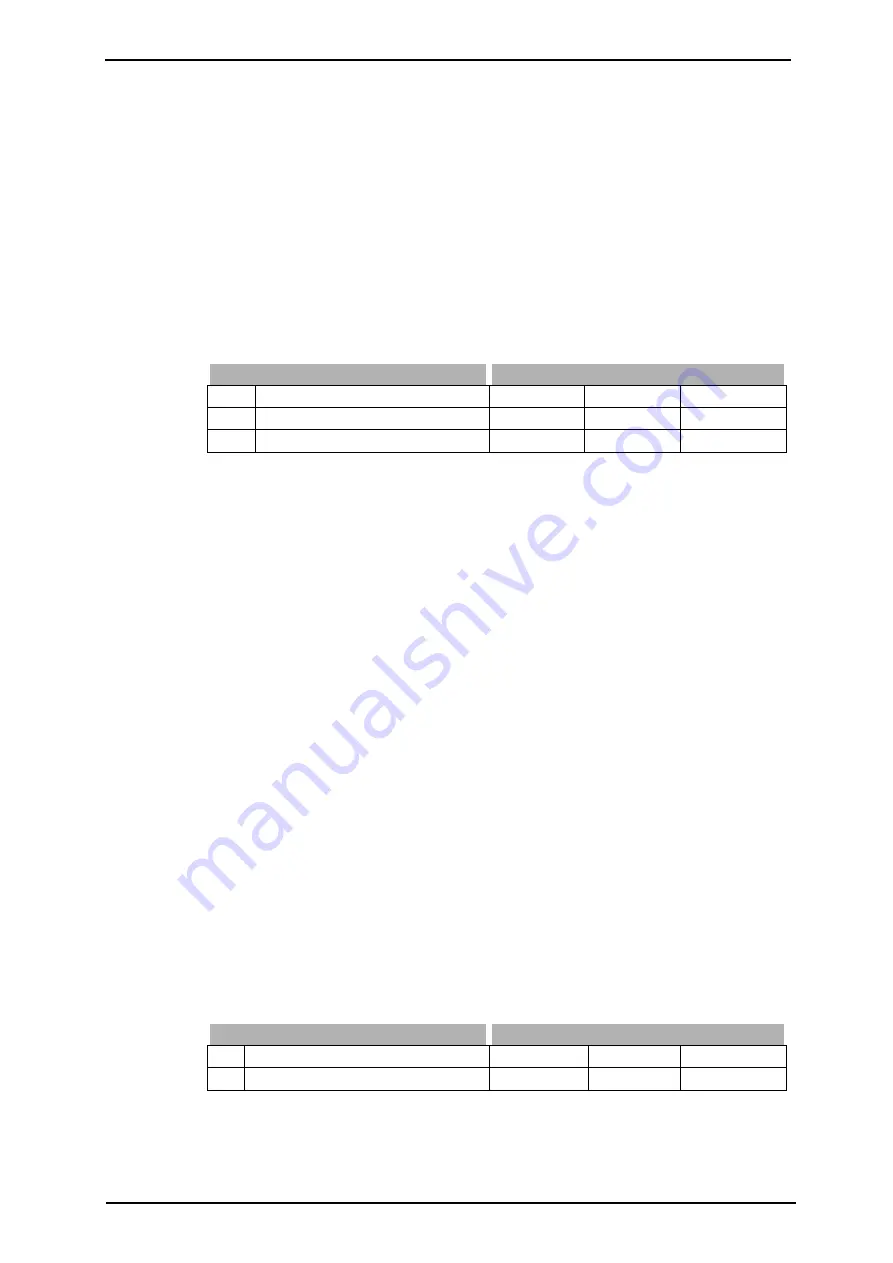

Parameter

Settings

No.

Description

Min.

Max.

Fact. sett.

377

Stator

resistance

1)

0 m

65535

m

R

sN

1190

Stator

resistance

2)

0.001

100.000

10.000

1)

Available in configurations 1xx, 2xx, 4xx (Parameter

Configuration

30

).

2)

Available in configurations 5xx (Parameter

Configuration

30

).

Stator resistance asynchronous motor:

The value of the stator resistance can be optimized while the machine is in no-load

operation. At the stationary operating point, the torque-forming current

Isq

216

and/or

the estimated

Active current

214

should be zero. Due to the temperature-dependent

of the stator resistance, the adjustment should be done at a winding temperature

which is also reached during normal operation.

A correct measurement will optimize the control functions.

Stator resistance asynchronous motor:

The value of the stator resistance of the synchronous motor is entered during the

guided commissioning. The value of the stator resistance is used for adjustments of

the current controller and should be therefore entered as exact as possible. The

sta-

tor resistance

1190

is the value between two motor phases and can be taken usually

from the data sheet of the motor.

9.2.2 Leakage

Coefficient

The leakage coefficient of the machine defines the ratio of the leakage inductivity to

the main inductivity. The torque and flux-forming current components are thus cou-

pled via the leakage coefficient. Optimization of the leakage coefficient within the

field-orientated control systems demands acceleration to various operating points of

the drive. Unlike the torque-forming current

Isq

216

, the flow-forming current

Isd

215

should be largely independent of the load torque. The flow-forming current compo-

nent is inversely proportional to the leakage coefficient. If the leakage coefficient is

increased, the torque-forming current increases and the flux-forming component

drops. The adjustment should result in a relatively constant actual current

Isd

215

,

matching the set

Rated magnetizing current

716

, regardless of the load on the drive.

The sensorless control system uses the parameter

Leakage coefficient

378

in order

to optimize the synchronization to one drive.

Parameter

Settings

No.

Description

Min.

Max.

Fact. sett.

378 Leakage Coefficient

1.0 %

20.0 %

7.0 %