45

CRIMPED CLEVIS

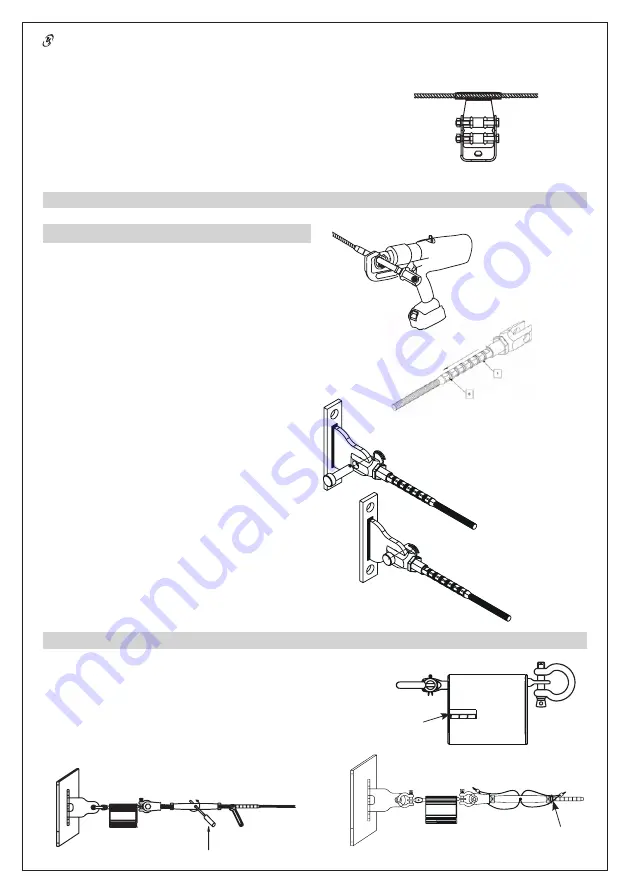

Once you have adjusted its length, introduce the cable into the FA 60 205

00 tensioner crimped clevis. At least 100 mm of cable must be fed into the

tube. Mark the cable to check the length introduced into the tube. If the

length measured is the minimum length required, reintroduce the cable into

the tube. Using the crimping tool, start crimping at point 1 by positioning

the crimper jaws in the centre of the crimp markers on the crimped clevis.

Continue crimping in the direction indicated on the drawing until you have

finished crimp No. 6. Rotate the crimping tube by 45° between crimps to

prevent it from becoming deformed over its length. Refer to the crimping

machine user instructions before commencing. When you have finished

crimping, apply coloured lacquer to the cable and tube which will act as an

indicator in case the cable slips inside the tube.

Particular care must be taken when carrying out this operation as it cannot

be reversed and it is central to the strength of the system and the safety

of its users.

FA 60 205 00

Next, pass the cable through all of the intermediate components.

The crimped clevis must be in its shortest position, i.e. fully screwed in and

locked with the nut (see the crimped clevis technical description drawing

in the technical file). Remove the pin from the clevis assembly shaft so that

it can be removed. Next, fit the crimped clevis to the end piece and put the

shaft back in position through the clevis and the end piece. Put the safety

pin back on the shaft.

INSTALLATION TENSION

Place the lifeline under tension using the FA 60 203 00 tensioner by rotating the

main tensioner body using a shaft going through the hole until the last absorber coil

touches the absorber’s tension indicator recess. The tensile force should then be of

the order of 80 to 100 daN.

When you have finished putting the system under tension, tighten up the 2 lock

nuts against the body of the tensioner to lock the assembly in place. Apply some

thread lock to the grub screws and screw them into the nuts.

Fit one anti-tamper seal

between the main tensioner body hole and its clevis and another between the main

tensioner body hole and the seal ring (see drawing opposite).

Tension indicator

Seal ring