5.8 Maintenance procedure

Maintenance

Maintenance every 1000 service hours

WA70-7 – VENAM02003

5-63

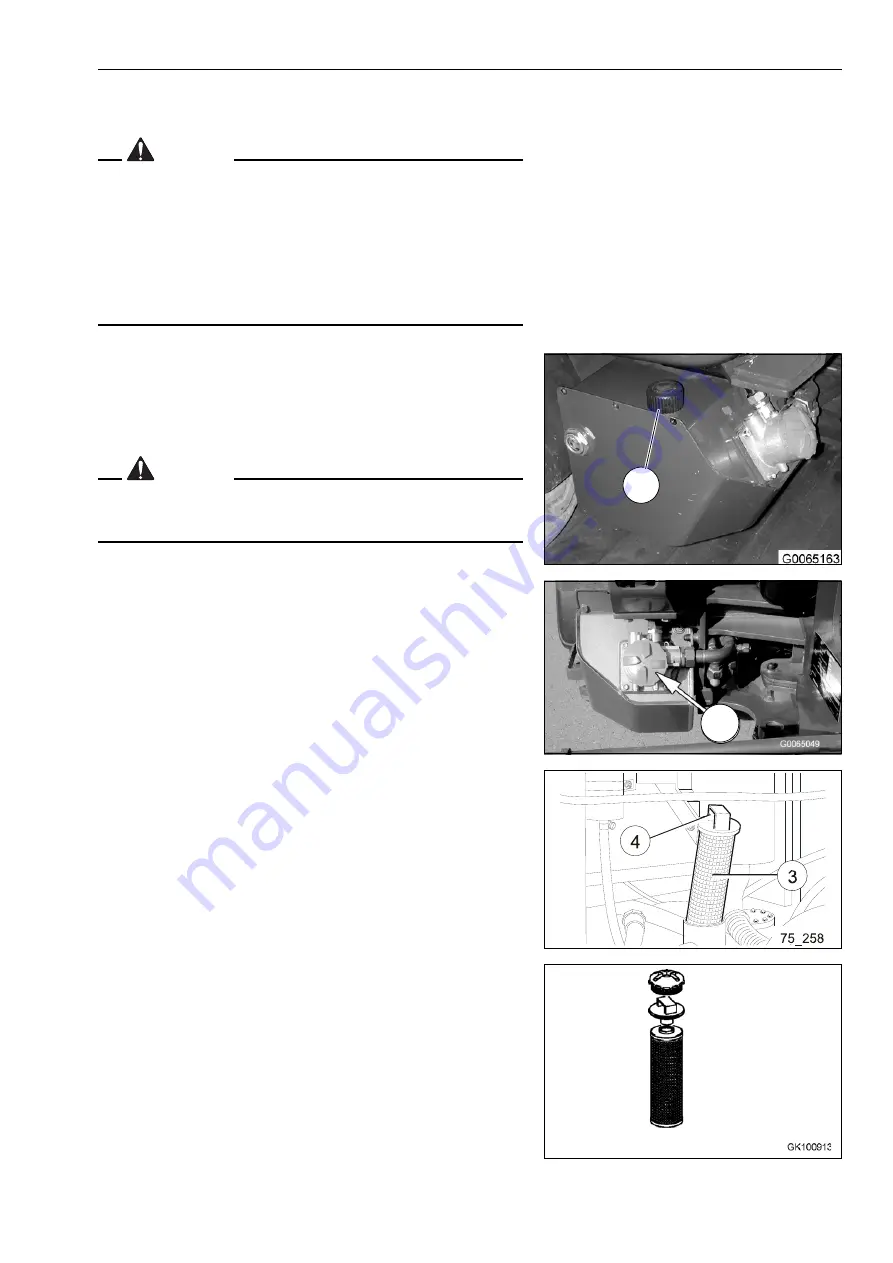

Hydraulic system – change filter insert

WARNING

Repeated skin contact with used hydraulic oil can cause skin

damage and other bodily harm!

Wear rubber gloves when changing the filter. Carefully wash

off hydraulic oil that has come into contact with the skin.

Use only the prescribed supporting prop to support the work

unit. Never use other objects as supports.

1. Park the machine on level, solid ground.

2. Raise the boom and tilt the bucket.

3. Apply the parking brake.

WARNING

Danger of injury caused by boom! It is only permitted to step into

the area below the boom if the boom is supported.

4. Position the supporting prop underneath the boom.

5. With the engine switched off, lower the boom slowly until it

rests safely on the supporting prop.

6. Loosen the venting filter (1) a few turns to let the pressure

escape.

7. Clean the filter cap (2) and the surrounding area.

8. Remove the filter cap.

9. Pull out the filter insert (3) at the handle (4).

10. Pull the filter insert off its handle and discard it.

11. Clean the inside of the filter. Check for foreign materials

before cleaning.

12. Attach the handle to a new filter insert.

13. Insert the new filter element into the housing.

14. Screw on the filter cap and tighten to 20 Nm.

15. Tighten the venting filter (1).

16. Start the engine.

17. Actuate the boom and bucket several times.

18. Check the hydraulic oil level.

19. Do a trial run to check that the system is leak-free.

1

22

Содержание WA70-7

Страница 2: ......

Страница 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Страница 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Страница 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Страница 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Страница 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Страница 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Страница 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Страница 276: ...5 8 Maintenance procedure Maintenance every 2000 service hours Maintenance 5 74 WA70 7 VENAM02003...

Страница 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Страница 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Страница 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Страница 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Страница 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Страница 298: ...Notes 9 2 WA70 7 VENAM02003...

Страница 299: ...Notes WA70 7 VENAM02003 9 3...

Страница 300: ...Notes 9 4 WA70 7 VENAM02003...

Страница 301: ...Notes WA70 7 VENAM02003 9 5...

Страница 302: ...Notes 9 6 WA70 7 VENAM02003...