5.1 Maintenance guide

Maintenance

5-6

WA70-7 – VENAM02003

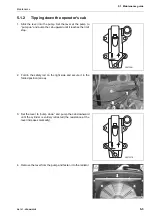

5. Lubricate the bolt (2) with copper paste.

6. Insert and tighten the retaining screws (2) for the cab (1 left,

1 right). Secure the screws with the retaining pins (1).

Torque = 500 Nm.

7. Close the bonnet.

Checking the service meter

Check the service meter reading every day to see if there is

maintenance work to be carried out.

Komatsu genuine replacement parts:

Use Komatsu genuine parts specified as replacement parts in

the Parts Book. In order to ensure safe assembly and operation

of the machine, it is recommended that you use Komatsu genu-

ine parts.

Komatsu genuine oils:

Use Komatsu genuine oils and grease. Choose oils and grease

with proper viscosities specified for ambient temperature.

Always use clean washer fluid:

Use ethanol-based window washer fluid and ensure it is not con-

taminated by dirt.

Always use clean oils and greases:

Use clean oils and lubricants. Also, keep the oil and lubricant

reservoirs clean. Prevent contamination of oils and greases by

foreign materials.

Checking for foreign materials in drained oil and in filters:

After changing the oil and filter, check the drained oil and the fil-

ters for metal particles and foreign materials. If large quantities

of metal particles or foreign materials are found, always report to

the person in charge and perform the necessary measures.

Fuel strainer:

Do not remove the strainer from the filler neck when refilling the

fuel tank.

2

1

Содержание WA70-7

Страница 2: ......

Страница 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Страница 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Страница 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Страница 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Страница 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Страница 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Страница 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Страница 276: ...5 8 Maintenance procedure Maintenance every 2000 service hours Maintenance 5 74 WA70 7 VENAM02003...

Страница 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Страница 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Страница 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Страница 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Страница 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Страница 298: ...Notes 9 2 WA70 7 VENAM02003...

Страница 299: ...Notes WA70 7 VENAM02003 9 3...

Страница 300: ...Notes 9 4 WA70 7 VENAM02003...

Страница 301: ...Notes WA70 7 VENAM02003 9 5...

Страница 302: ...Notes 9 6 WA70 7 VENAM02003...