5.8 Maintenance procedure

Maintenance

When required

WA70-7 – VENAM02003

5-29

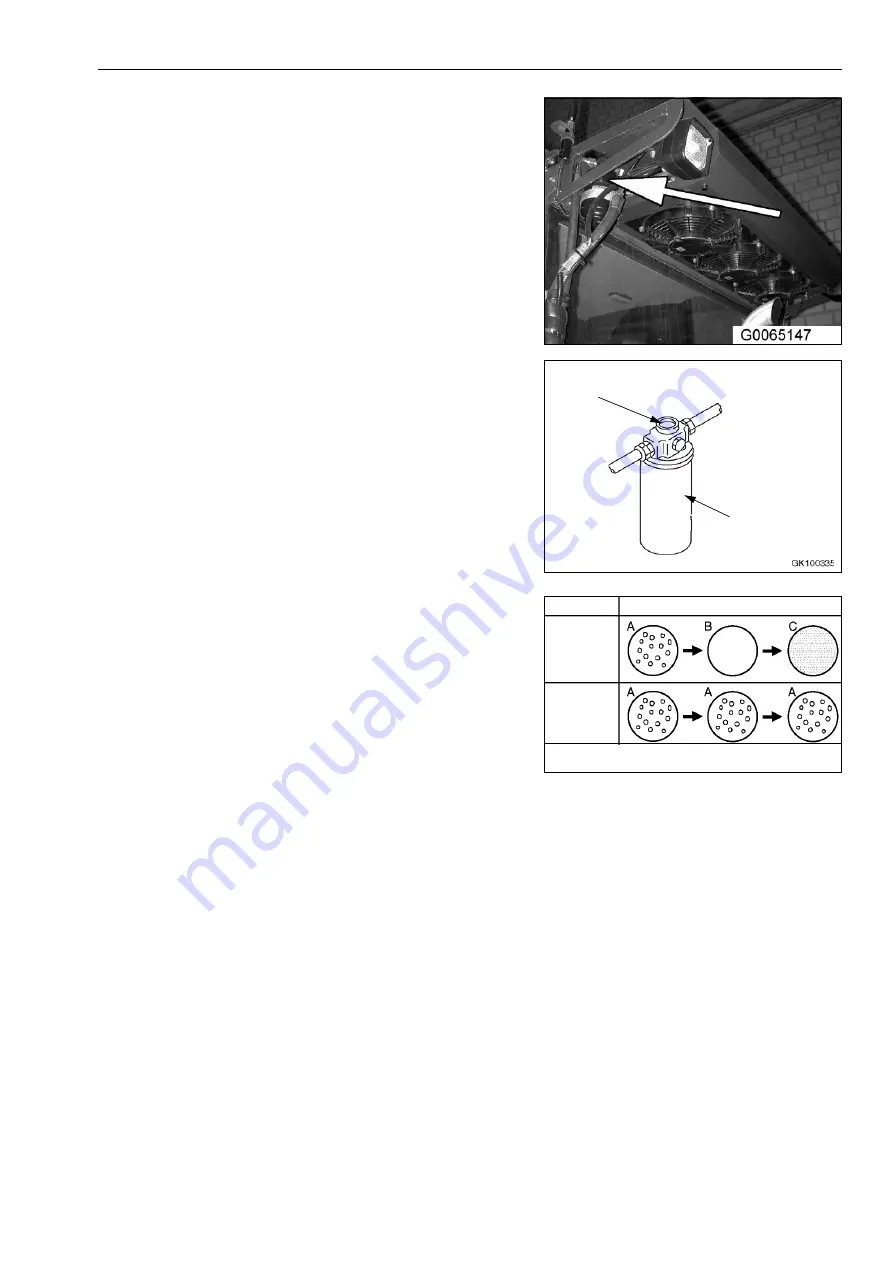

If the cooling effect of the air conditioner is poor, this may be

caused by lack of refrigerant (gas).

In this case, check the sight glass (2) of the filter dryer (1). The

sight glass is installed at the side of the condenser, on the con-

tainer.

Create the following conditions before inspecting:

Start the engine and let it run at 1000 rpm.

Turn the air conditioner ON.

Set the airflow to maximum.

Set the temperature to minimum.

Open the doors and windows fully.

Turn the air conditioner switch ON.

If the condition of sight glass (2) is “correct” as shown in the dia-

gram on the right, the condition is normal. (When the air condi-

tioner is switched on, you will see a few bubbles. After this, the

liquid takes on a translucent, milky white colour.)

If the condition of sight glass (2) is “insufficient” as shown in the

diagram on the right, the refrigerant level is too low. Consult your

Komatsu distributor.

(When the air conditioner is switched on, there will always be a

few bubbles.)

Operating the air conditioner off-season

Even during the off-season, operate the air conditioner for 3–5

minutes once a month to maintain the oil film at all parts of the

compressor.

1

2

Status at the sight glass

Refrigerant

Correct

Insufficient

Level

A =

Bubbles in the liquid refrigerant

B =

The refrigerant is clear

C =

Oil and refrigerant are separated; liquid is a thin, milky

white.

Содержание WA70-7

Страница 2: ......

Страница 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Страница 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Страница 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Страница 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Страница 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Страница 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Страница 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Страница 276: ...5 8 Maintenance procedure Maintenance every 2000 service hours Maintenance 5 74 WA70 7 VENAM02003...

Страница 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Страница 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Страница 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Страница 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Страница 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Страница 298: ...Notes 9 2 WA70 7 VENAM02003...

Страница 299: ...Notes WA70 7 VENAM02003 9 3...

Страница 300: ...Notes 9 4 WA70 7 VENAM02003...

Страница 301: ...Notes WA70 7 VENAM02003 9 5...

Страница 302: ...Notes 9 6 WA70 7 VENAM02003...