Page 6.1 - 4

COMBIVERT R6-S

© KEB, 2008-02

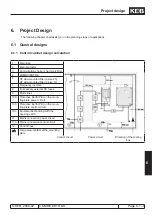

Project design

Control cabinet surface

Calculation of control cabinet surface:

Air flow rate with fan cooling:

P

V

—

‒

———

∆

T • K

3,1 • P

V

——

‒

——

∆

t

A =

[m

2

]

V =

[m

3

/h]

A

=

Control cabinet surface

[m

2

]

∆

t

=

temperature differential

(standard value = 20K)

[K]

K

=

coefficient of heat transmission

(standard value = 5)

P

V

=

power loss (see technical data)

V

=

air flow rate of fan

For more details please refer to the catalogs of the control cabinet manufacturers.

The COMBIVERT R6 serves in the operating mode as power supply and regenerative unit for supply of a DC

bus with the connected components (inverters). Furthermore the supplied regenerative energy of the DC bus

is refeed into the net via COMBIVERT R6.

A ‚sinusoidal‘ supply and regenerative current establishes in

connection with a harmonic filter.

In operational case ‚feed-in‘ approx. 8% THD.

In operational case ‚regeneration‘ approx.12% THD.

Several R6 units can be switched parallelly to increase the supply and regenerative power.

The following basic requirements must be met for the operation as power supply and regenerative unit (stan-

dard operating mode):

- The sum of the DC link capacities of the connected inverters may not exceed the max. permissible DC

link capacity of the R6 units.

- The maximum motor DC load

current of the connected drive must be ≤ than the maximum DC supply

current of the R6 unit.

- The motor DC load

current in continuous operation must be ≤ than the DC supply

rated current.

Observe OL function at high load currents.

- The maximum regenerative DC load

current of the connected drive must be ≤ than the max. DC regene

-

rative current.

- The regenerative DC load

current in continuous operation must be ≤ than the DC regenerative

rated

current.

Observe OL function at high load currents.

- The maximum permissible DC link capacity can be taken from the power data of the respective regene-

rative units!

∑ C

ZK capacitors

≤ max. permissible DC

link capacity

Содержание combivert R6-S

Страница 1: ...APPLICATION MANUAL Mat No Rev 00R6SEA K130 1 A GB KEB COMBIVERT R6 S Version 1 3 ...

Страница 2: ...Page 1 1 2 COMBIVERT R6 S KEB 2008 02 Introduction ...

Страница 4: ...Page 1 1 4 COMBIVERT R6 S KEB 2008 02 Introduction ...

Страница 14: ...Page 1 2 6 COMBIVERT R6 S KEB 2008 02 Product overview ...

Страница 28: ...Page 2 1 6 COMBIVERT R6 S KEB 2008 02 Fundamentals ...

Страница 34: ...Page 2 2 6 COMBIVERT R6 S KEB 2008 02 Password structure ...

Страница 40: ...Page 3 1 2 COMBIVERT R6 S KEB 2008 02 Parameter overview 3 1 1 Parameter list F5 A E and H 3 1 3 ...

Страница 116: ...Page 3 8 2 COMBIVERT R6 S KEB 2008 02 Special functions 3 8 1 Program timer counter 3 8 3 ...

Страница 130: ...Page 3 9 10 COMBIVERT R6 S KEB 2008 02 Define CP Parameters ...

Страница 140: ...Page4 2 2 COMBIVERT R6 S KEB 2008 02 Start up ...

Страница 144: ...Page4 2 6 COMBIVERT R6 S KEB 2008 02 Start up ...

Страница 146: ...Page 5 1 2 COMBIVERT R6 S KEB 2008 02 Error assistance 5 1 1 General 5 1 3 5 1 2 Error messages and their causes 5 1 3 ...

Страница 150: ...Page 5 1 6 COMBIVERT R6 S KEB 2008 02 Error assistance ...

Страница 158: ...Page 6 1 8 COMBIVERT R6 S KEB 2008 02 Project design ...

Страница 160: ...Seite 7 1 2 COMBIVERT R6 S KEB 2008 02 Annex 7 1 1 Keyword index 7 1 3 ...

Страница 166: ......

Страница 167: ......