10

OODMANUAL 0720

KAM CONTROLS, INC.

15.

Re-tighten the Socket Cap Screws so that the gaps between the two halves of the locking collar are the same

distance. FIG. 3-12.

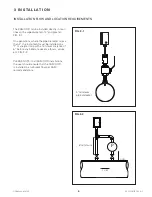

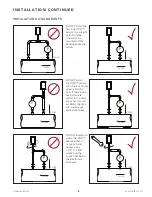

11.

Bolt or screw the OOD™ sensor to the valve.

(KAM CONTROLS recommends using thread sealant and not Teflon tape for the threaded OOD™).

12.

Slowly open Full-opening Ball Valve and check for leaks.

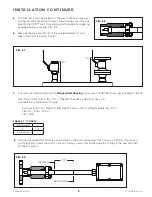

13.

Using a 3/8" Allen wrench, loosen Socket Cap Screws on the Locking Collar.

14.

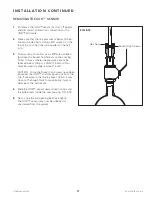

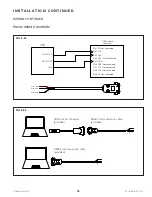

Push the OOD™ in until the Second Mark is at the top edge of the Locking Collar. FIG. 3-11.

FIG. 3-11

I N S TA L L AT I O N C O N T I N U E D

Second Mark

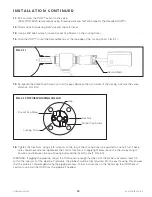

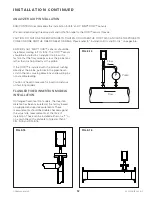

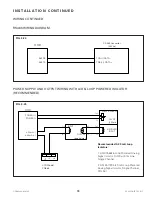

16.

Tighten the Hex Nuts, using a 3/4" wrench, on the top of the Locking Collar one quarter to one half turn. These

nuts should never be over tightened. Their major function is to apply light pressure on the chevron packing to

ensure a seal between the seal housing body and the insertion shaft. FIG. 3-12.

WARNING: If pigging the pipeline, retract the OOD sensor enough that the tip of the probe is located at least 1/4"

within the inner wall of the pipeline. Preferably, the probe should be fully retracted into the seal housing. This ensures

that the probe is not damaged during the pigging process. Follow instructions on the "Removing the OOD Sensor"

section to uninstall the OOD from the pipeline if needed.

SECTION A-A

SCALE 1 / 2

1

1

2

2

A

A

B

B

MATERIAL

FINISH

DRN

THIS DRAWING IN DESIGN AND

DETAIL IS THE PROPERTY OF

KAM CONTROLS INCORPORATED.

IT SHALL NOT BE REPRODICED

AND SHALL BE RETURNED TO US

ON DEMAND

ALL RIGHTS RESERVED

APPVD

SCALE

DATE

DWG NO.

REV

TITLE

UNLESS OTHERWISE

SPECIFIED

ALL DIM IN INCHES

ANGULAR TOL ±1/2

FRACTIONAL TOL ±1/64

3 PLACE DEC ±0.005

2 PLACE DEC ±0.010

REMOVE ALL BURRS

BREAK SHARP EDGES

DO NOT SCALE DWG

SHEET

SS316

Gerry Alejos

1:2

03-13-2013

A

2"-150 Seal Housing

Assembly

211-001-000

Kam

Controls

Incorporated

3939 Ann Arbor Dr.

Houston TX 77063

USA

WWW.KAM.COM

1

OF 1

A

1/4

5/32

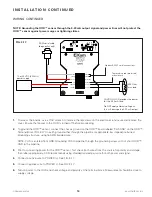

FIG. 3-12 TOP VIEW LOCKING COLLAR

Socket Cap Screw

Socket Cap Screw

Locking Collar

Gap

Hex Nut