WARNING

Compressed air!

Compressed air and devices under pressure can injure or cause death if the contained energy is

released suddenly or uncontrolled.

➤ Make sure all components and vessels are depressurized and the user's pressure gauge reads

0 bar.

2. Disconnect the hose line from the check valve.

3. Loosen the hexagon nuts and exchange antivibration pads for machine mountings.

4. Removing the air filter

5. Screw the elbow to the cylinder head and the filter to the elbow.

6.8.3 Fitting the Sound Enclosure

Precondition The antivibration pads are removed and machine mountings fitted.

The air filter is fitted.

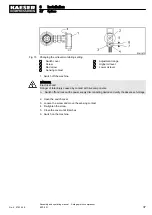

Fig. 19 Fitting the Sound Enclosure

1

Compressor block

2

Base plate

3

Machine mounting pad

4

Air cooler

5

Hose

6

User's check valve

7

Sheet metal ring

8

Pre-cut foam

9

Air inlet soundproofing box

10

Sound enclosure

11

Snap fastener

12

Panel (exhaust louver)

1. Set the machine on the base plate and secure the machine mountings.

2. Fix the sheet metal ring to the cooler with the fixings provided and slide the foam collar over the

ring.

3. Lead cables and pipes through the holes provided and connect up.

4. Fix the enclosure to the base plate.

5. Screw the air inlet soundproofing box to the enclosure, hang the panel with exhaust louvers in

the enclosure and fix with the snap fasteners.

6

Installation

6.8

Retrofitting the Sound Enclosure (accessory)

40

Assembly and operating manual 2-stage piston compressor

EPC-2-G

No.: 9_5753_04 E

Содержание EPC 1000-2-G

Страница 2: ...Original instructions KKW PEPC 1 04 en SBA KOLBEN AGGREGAT 2 STUFIG...

Страница 6: ...Contents iv Assembly and operating manual 2 stage piston compressor EPC 2 G No 9_5753_04 E...

Страница 10: ...List of Tables viii Assembly and operating manual 2 stage piston compressor EPC 2 G No 9_5753_04 E...