REV

. 10

22-04-2020

INSTALLATION

,

USE AND MAINTENANCE MANUAL

–

PN

20 / 40

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

T

EL

. +39 0434 636811 F

AX

. +39 0434 636812

http://www.jurop.it

e-mail: [email protected]

-

+

½ giro

40 – 80 g/h

Assemble operation

• Lubricate and then insert all the vanes into their seats (1).

• Reassemble the components in the following order:

Decompressor flange (2): avoid damaging the seal rings (8)

while fitting them on the shaft. Centre properly and tighten the

screws. Insert the bearings (10) and (12) properly and all the

way into their seats. It is recommended to replace the O-Ring

(1).

Gear wheel (4) with relative bearing (11) and seal ring (7).

Pinion (5) and self-locking flanged nut (14)

Gear box and its gasket.

Cardan shaft guard.

Attention: do not damage the components during

assembly by forcing them excessively.

General warnings

• When changing the vanes do not forget to carefully clean all the

components that you have dismantled. Clean the oil filter and the oil

tank from the solid sediments. The models PN 106, are provided with a

side oil tank; be careful to the maximum tight torque of the oil filter plug.

Maximum torque: 10Nm.

• The front bearing has been greased during pump’s assembling.

Lubrication of said bearing is necessary after long working periods only

(for example, normal duration of a set of vanes). It is consequentely

suggested to pump carefully new grease through the lubrication nipple

in order to avoid damages to the seals.

• Procedure for tightening the self-locking flanged nut on the rotor:

FFasten the decompressor to a bench or to the machine

frame.

Fit the feather key and flange on the rotor. Use a pad and a

hammer to put the half-joint fully into place correctly.

Fully tighten the nut by hand.

Lock the rotor rotation.

Start tightening the nut with a suitably calibrated torque

wrench: 100 Nm for M20X15 nut (PN23-33); 250Nm for M24X2

nut (PN45-…-106).

For final tightening, use a torque wrench set at 160 Nm for

M20X15 nut (PN23-33) and 350Nm for M24X2 nut (PN45- ... -

106).

Carry out a continuous movement of about 30° without

interruptions until the nut stops when the wrench clicks at the

set torque.

Mounting the hydraulic drive

• We recommend the drive coupling be oiled when vanes are being

replaced.

• However lubricate the drive coupling every 1500 hours.

We recommend the drive coupling be oiled every

1500 hours.

• Apply coupling hub to vacuum pump axis respecting the position

marked during disassembly: the grain must go back into the seat on the

rim.

• Mount the coupling and lubricate internally with NLGI 2 Lithium

grease. Provide an adequate quantity of fat, in order to have a medium

filling.

• Reassembly the motor without forcing onto the seals.

Adjusting the self-lubricating pump

• Only for decompressors equipped with automatic lubrication

pump.

• The automatic lubricating pump is adjusted by the manufacturer

before the shipping.

• If consumption noticeably differs from the indicated value, adjust it

as follows:

-

Remove the upper protection cover;

-

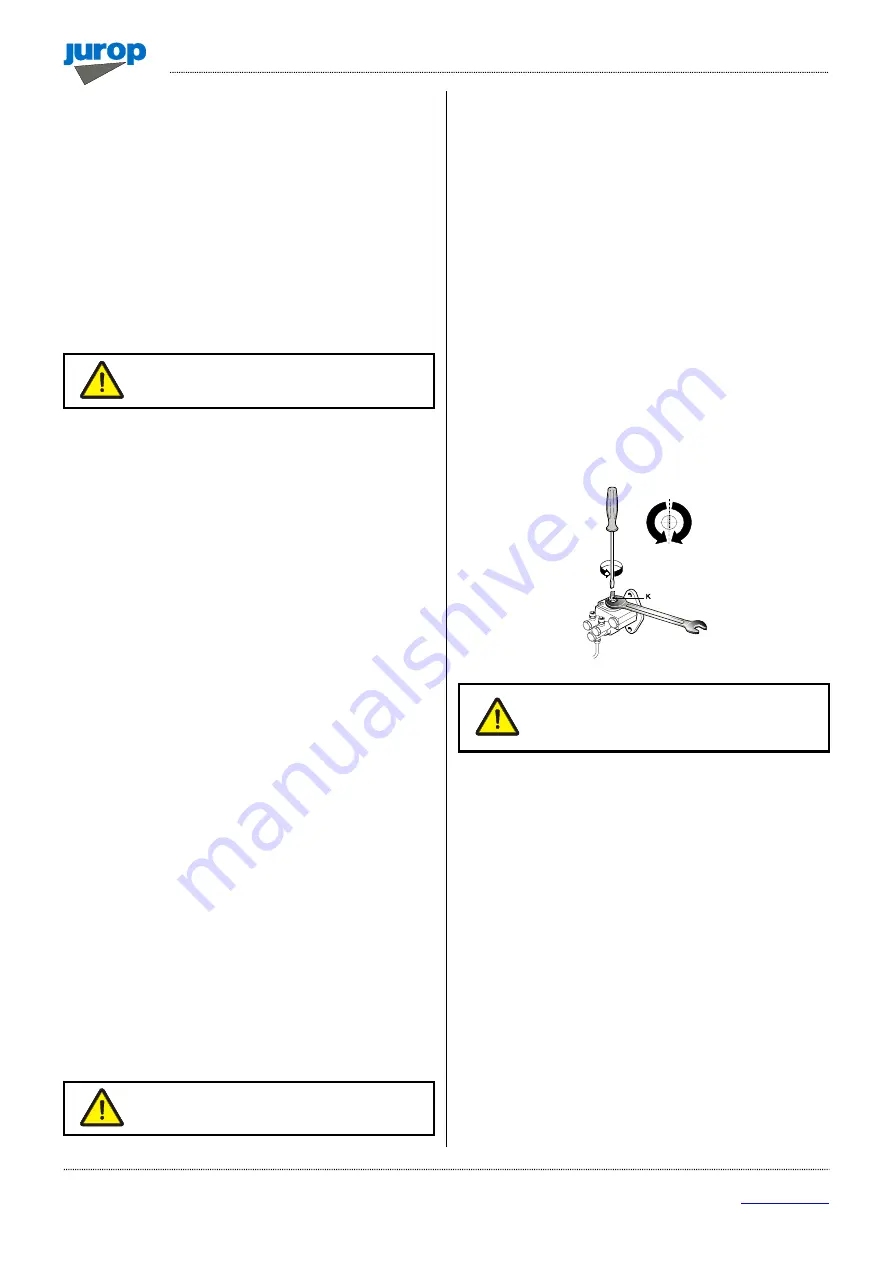

Using a screwdriver and a 10 mm wrench, adjust the adjusting

screw (K). Close the nut and remount the upper protection cover;

-

It is advisable to turn the screw of ¼ of turn and verify the actual

consumption.

Pic. 6.9

Do not reduce oil consumption below the value

indicated in par. 2.2 (for functioning at speeds

different from the maximum, flow is proportionate

to rotating speed).

• ½ turn of the adjusting screw causes a variation in the flow of

approximately

40 - 80 g/h

, depending on using conditions.

Cleaning of the inside exhaust port of the pump housing

• Frequency: at every changing of the vanes.

• How to proceed: dismantle the manifold and remove possible

oilscales or other foreign parts.

• The clogging-up of this manifold and the exhaust port depends

mainly from heavy duty use of the pump and causes an increase of

temperature and a non-perfect closing of the check valve. A careful

cleaning of all components, including the insides of the housing and the

non-return check valve and its seat, is therefore strongly

recommended.