REV

. 10

22-04-2020

INSTALLATION

,

USE AND MAINTENANCE MANUAL

–

PN

17 / 40

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

T

EL

. +39 0434 636811 F

AX

. +39 0434 636812

http://www.jurop.it

e-mail: [email protected]

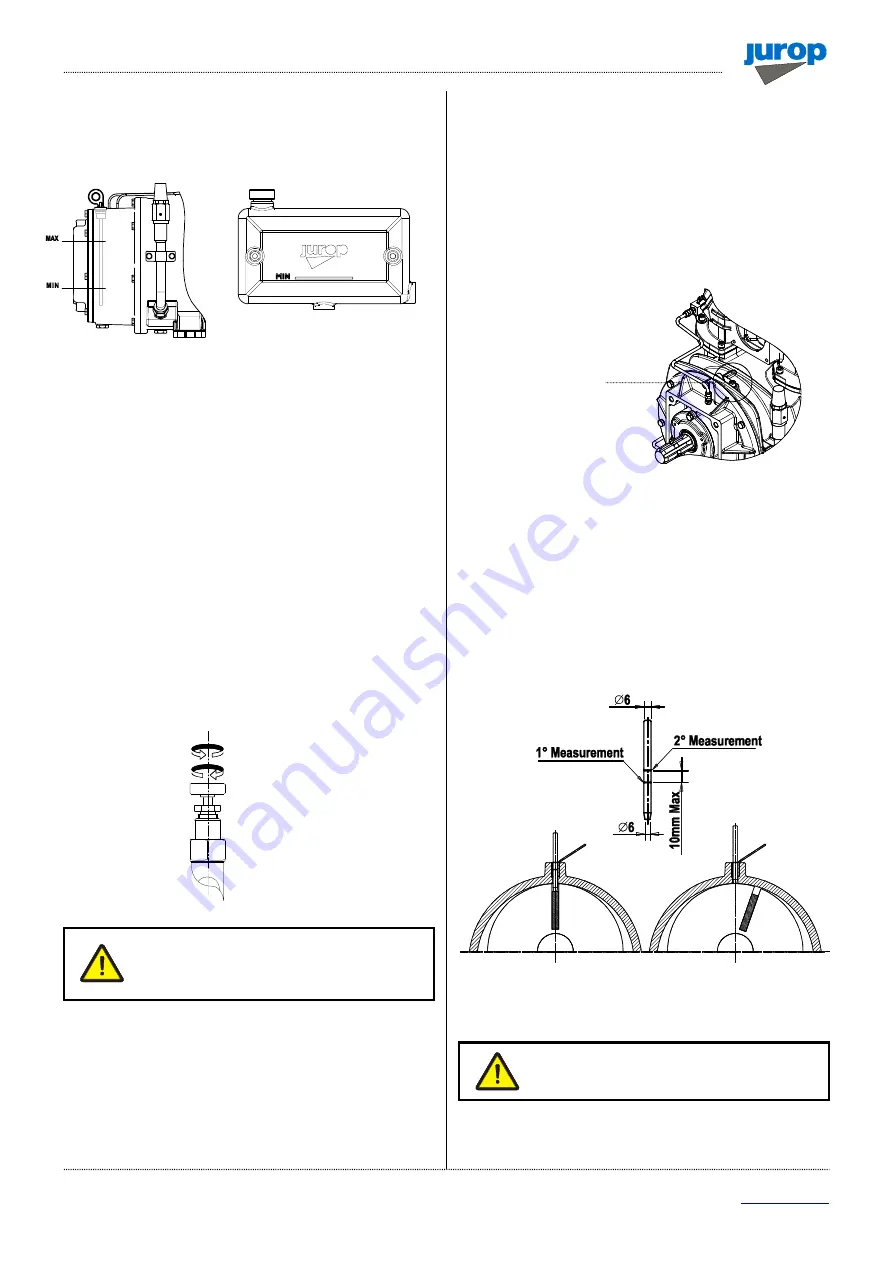

Checking the oil tank level

• Before starting the machine, check the lubricating oil level.

Pic. 6.1

• Do not run the pump with oil level under the minimum level: that

may lead to dry functioning and cause serious damages. (Pic. 6.1).

• Rear mounted tank capacity:

1,2 l (PN 23-33)

and

3,2 l (PN45-58-

84-106)

.

• Side mounted tank capacity:

4 l

.

• Also check that the oil level in the gearbox reaches the side level

hole. Top up through the hole in the upper part.

• Top up with fresh and clean oil only; use the oil required in

paragraph 2.5 or equivalent.

Checking lubrification

• Keep clean the oilers glasses and check dripping into the same

oilers.

• Check dripping in the oilers on a frequent basis during operation.

• Be sure it is regular (about 45-50 drops/min at 1300 rpm) to grant a

correct lubrication of the pump. At lower speeds, the number of drops

must be directly proportional.

Pic. 6.2

If there is no lubrication, the machine overheats

and the internal components deteriorate quickly.

Stop the machine, check the oil level and the

lubrication pump.

Checking the vanes wear (PN23…58)

• Carry out the inspection by removing the manifold. Insert, near the

outlet/inlet, a 6 mm diameter dipstick with the chamfered end facing

towards the bottom. After resting the dipstick on the rotor, carry out a

first measurement by making a mark on the dipstick.

• Turn the shaft manually and rest the rod on the outer diameter of

the rotor, making a mark on it, turn the shaft again until the rod enters

the vane slot, mark it again and measure the difference between the

two marks.

• Repeat the operation on all the vanes. If the difference exceeds 10

mm, the vanes must be replaced as soon as possible. Replace all the

vanes at the same time.

• At the end of the operation, reassemble the manifold.

Checking the vanes wear (PN84 - PN106)

• Unscrew the vanes wear check-plug on the front flange. See Pic.

6.3.

Pic. 6.3

• Turn the shaft by hand until vanes appearance.

• Vanes usually slip on seat bottom due to gravity. Check their right

entry in the seat.

• Inserire, come in Fig. 6.4, un’astina Ø 6 mm.

• Turn the rotor slowly until the stick touches the vane in idle

position in its seat. The vanes slide to the bottom of the seat due to

gravity: check they really do and mark again on the stick.

• Repeat the same procedure for all the vanes. If wear exceeds 10

mm: replace the vanes as soon as possible.

Pic. 6.4

• Replace all the pump vanes at the same time.

Replace the vanes when their wear exceeds 10

mm (L – L min): they may break. Replace all

vanes at the same time.

• At the end of this checking do not forget to replace the plug on the

port.

VANES

CHECK

-

PLUG

+

OLIO

(

MAX

)

-

OLIO

(

MIN

)

REAR MOUNTED TANK

SIDE MOUNTED TANK