REV

. 10

22-04-2020

INSTALLATION

,

USE AND MAINTENANCE MANUAL

–

PN

11 / 40

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

T

EL

. +39 0434 636811 F

AX

. +39 0434 636812

http://www.jurop.it

e-mail: [email protected]

• The machine expels gas during delivery at temperatures that can

reach the maximum permitted values for operation, with its lubricating

oil in suspension. Oil consumption is stated in paragraph 2.2, the

quantity of consumed oil corresponds to the quantity of oil emitted at

delivery.

• In case of PN with hydraulic motor, provide the necessary space

to disassemble the motor itself and proceed with joint lubrication.

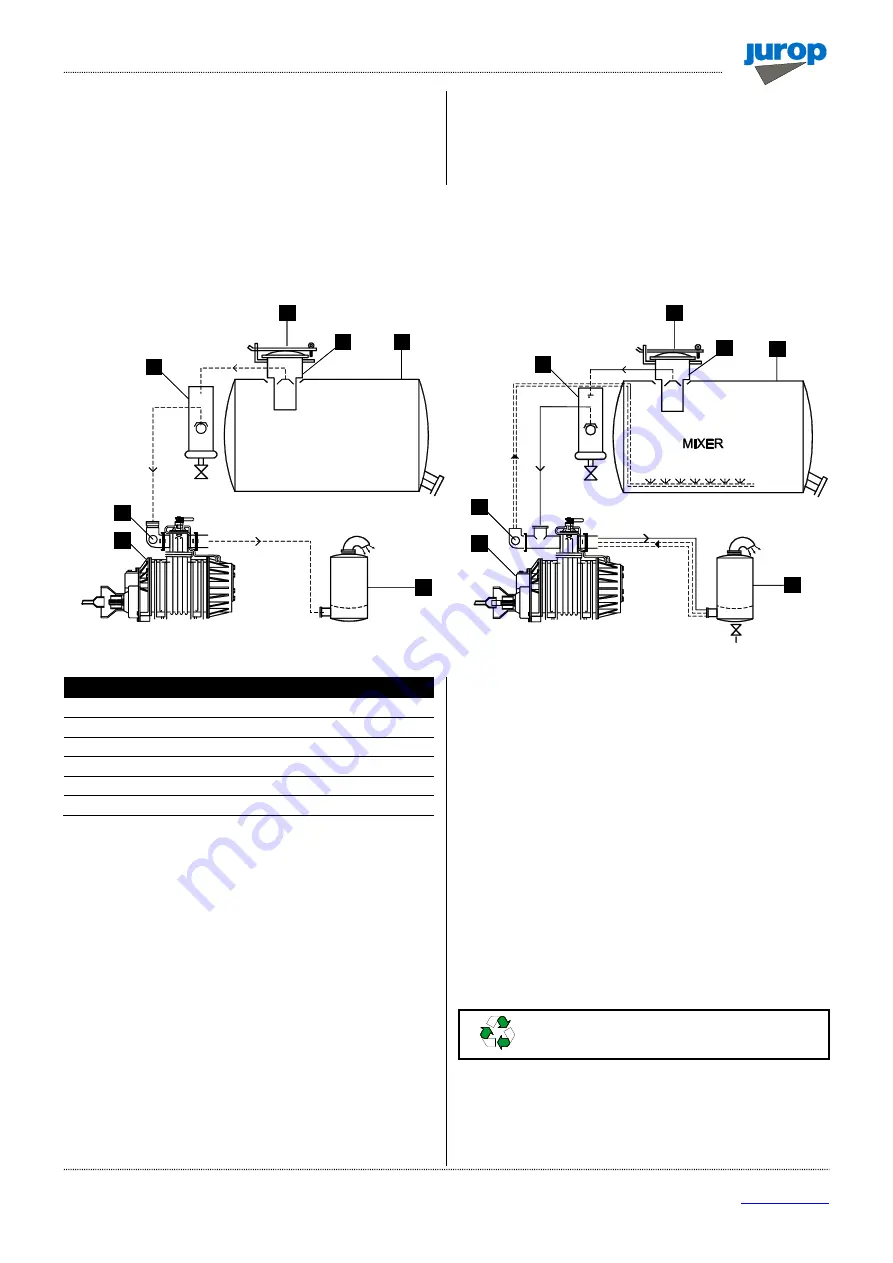

4.6. Vacuum / Pressure line

• See the following picture.

Pic. 4.2

Vacuum / Pressure line components

1

Primary shutoff

2

Tank

3

Secondary shutoff

4

Si oil trap

5

PN pump

6

Safety relief valve

• The hoses connecting the suction and exhaust ports of the

vacuum pump must be of adequate diameter (suggested not less than

3”) and of oil and corrosion resistant materials and before connecting

them, make sure that they are perfectly clean in the inside.

• The weight or dimensions of the pipes must in no way stress the

pump body. Use high temperature resistant rubber sleeves.

• Remove the port guards when mounting. The pipes and

components of the whole line must be clean.

• Avoid constrictions and tight curves where they are not essential.

• Connect the pump to the tank through the suction manifold which

has a threaded port for fitting the over-pressure valve.

• The exhaust pipes can reach high temperatures. Protect those

adequately from the operator reach.

• A non-return valve on suction pipe avoids rotation in the opposite

direction when the pump stops.

• To avoid that foreign liquids will enter the vacuum pump it is

necessary to mount on the suction line an over-flow valve of “floating-

ball” type (Fig. 4.2. - pos. 1). The flow section of this valve must be

equivalent to the suction hose’s one.

• It is also necessary to have on the line a suitable air filter for

preventing solids to be sucked inside the vacuum pump. It is also

recommended to mount a “secondary shutoff” of floating-ball type (Fig.

4.2 - pos. 3) between vacuum pump and over-flow (primary shutoff).

• Called also 4-way valve, normally is manually operated but it can

be at any time transformed in pneumatically or hydraulic operated upon

request of the appropriate kit.

• During normal running of the pump the resulting noise should be

reduced by means of a suitable silencer (Fig. 4.2 - pos. 4) mounted as

close as possible to the pump itself. It has to be dimensioned for the air

flow produced by the pump model. The oil used for the pump’s inside

lubrication has to be separated from the exhausted air by means of an

adequate oil-separator, placed directly inside the silencer. The silencer

is fitted also with a draining tap for the collected oil and condensed

liquids.

Do not dispose of in the environment. Dispose of

in compliance with the standards in force.

• Over-pressure safety relief valves (Pic. 4.2 - pos. 6). It must be

dimensioned to discharge the entire air-flow of the pump. The

adjustment of this valve has to be kept inside 10% of tolerance of the

pump's working pressure and in any case, it has to stay inside the

given value of the tank's work pressure.

3

5

4

6

1

2

5

6

4

3

2

6

6

1

PN PUMP WITH STANDARD MANIFOLD

PN PUMP WITH MIXER MANIFOLD